UV Protection for Garage Floors

December 12, 2025

Every time sunlight hits your garage floor, it’s causing damage – whether you notice it or not. UV rays fade colors, weaken concrete, and degrade standard coatings like epoxy. Over time, this leads to cracks, peeling, and a worn-out look that’s hard to fix.

The solution? UV-resistant coatings. These advanced systems, including polyurea and polyaspartic options, are specifically designed to withstand sunlight while maintaining their color, strength, and durability. Unlike traditional epoxy, they don’t yellow, crack, or fail under heat or UV exposure—a key advantage in polyurea vs. epoxy UV stability.

Here’s what you need to know:

- UV rays damage concrete and coatings by increasing porosity, causing microcracks, and fading colors.

- Standard epoxy coatings fail with yellowing, peeling, and structural weakness under sunlight.

- UV-resistant coatings offer long-term protection, keeping your garage floor strong, attractive, and safe.

For the best results, look for coatings with UV stability, color retention, and resistance to heat, abrasion, and chemicals. Polyurea and polyaspartic systems, like the Penntek Evolution system from Croc Coatings, provide superior performance and come with a lifetime warranty.

How UV Exposure Damages Garage Floors

Concrete Surface Breakdown

When bare concrete is exposed to UV rays, it heats up, leading to daily cycles of expansion and contraction. Over time, this creates tiny, often invisible microcracks. Once moisture seeps into these cracks, the deterioration speeds up, causing erosion, more cracks, and even chips. In areas like North Idaho and Eastern Washington, where temperatures swing from below freezing in winter to over 90°F in summer, the freeze-thaw cycle adds to the damage. This process leaves the surface weak, dusty, and chalky, setting the stage for coatings to fail and the floor’s appearance to degrade.

Color Changes in Standard Coatings

Epoxy garage floors have pros and cons, but they don’t stand up well to UV exposure. Over time, they can fade or discolor noticeably. Surprisingly, even indoor UV light from electric bulbs can contribute to this issue, so the floor is at risk whether the garage door is open or closed. This fading not only diminishes the floor’s visual appeal but also undermines the durability of your investment.

Coating Failure from Heat and Sun

UV exposure doesn’t just affect how the floor looks – it can also weaken the structure of floor coatings. Sunlight heats the surface, causing the coating to expand, and as temperatures cool at night, it contracts. This constant movement puts stress on standard coatings, which often can’t handle the strain. Early signs of trouble include small bubbles or blisters where the coating starts to pull away from the concrete. Over time, peeling and cracking occur, especially along edges or in areas that get the most direct sunlight. As the coating becomes brittle and loses its flexibility, it not only looks worse but also stops protecting the surface effectively, leading to further safety concerns.

Reduced Safety and Home Value

UV damage doesn’t just look bad – it can also create safety hazards and hurt your home’s value. Cracked or chipped surfaces can become tripping hazards, and damaged floors are more likely to absorb stains, making them harder to clean. For homeowners looking to sell, a worn or neglected garage floor can signal poor maintenance to potential buyers, potentially lowering the property’s appeal and market value.

You are being MISLED about EPOXY GARAGE FLOORS…

How UV-Resistant Coatings Solve These Problems

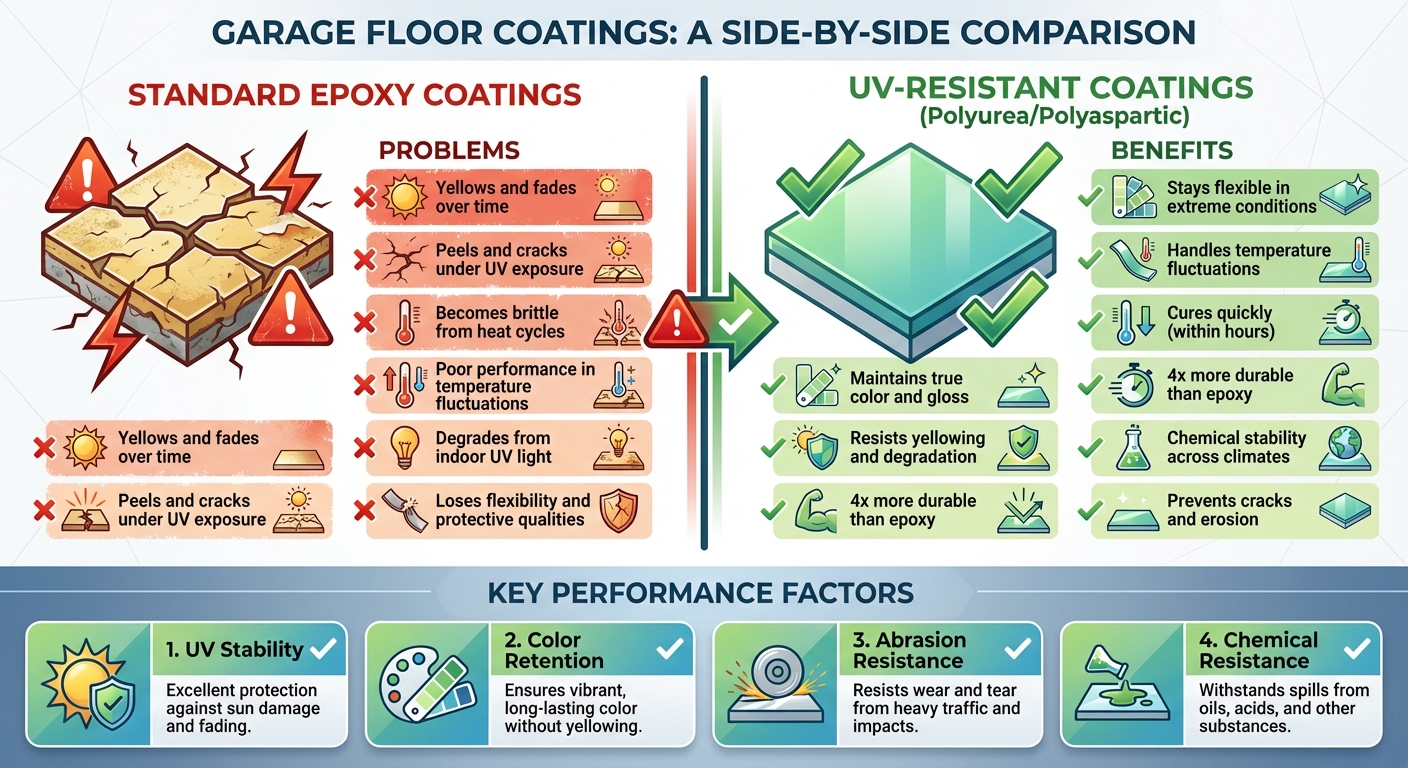

Standard Epoxy vs UV-Resistant Coatings for Garage Floors

UV-resistant coatings tackle the challenges caused by prolonged exposure to sunlight, offering both protection and durability for floors.

UV-Stable Formulas Protect Against Damage

These coatings are crafted with advanced resins designed to withstand extended UV exposure. Unlike standard epoxies that often yellow or degrade over time, UV-resistant coatings act as a shield, protecting both the coating itself and the concrete beneath from harmful radiation. This ensures the floor stays strong and visually appealing for years. Plus, their chemical stability means they can handle a variety of climates without compromising performance.

Superior Performance in Sun and Extreme Conditions

UV-resistant coatings create a tough, protective layer that resists porosity, carbonation, and heat-induced expansion. They cure quickly and remain flexible, even in humid or extreme temperature conditions. For garages that face drastic temperature changes, polyurea and polyaspartic systems are especially effective. They prevent cracks, erosion, and warping caused by direct sunlight. Additionally, their ability to handle humidity during application and adjust to thermal expansion makes them ideal for garages without climate control. Beyond their structural benefits, they also maintain a polished and attractive appearance.

Long-Lasting Aesthetic Appeal

One of the standout features of UV-resistant coatings is their ability to retain their original look over time. They maintain true color, consistent gloss, and a smooth finish, eliminating the common problems of yellowing, chalking, or dullness that plague standard epoxy floors. This lasting beauty not only reduces the need for frequent maintenance but also enhances the overall look of your home for years to come.

sbb-itb-a0e5ae3

Selecting a UV-Resistant Coating for Your Garage

Protecting your garage floor from UV damage starts with choosing the right coating. The right product ensures your floor not only looks great but also stands up to wear and tear over time.

Key Performance Factors to Look For

When evaluating UV-resistant coatings, keep an eye on four key performance factors:

- UV stability: Prevents yellowing and degradation caused by sunlight.

- Color retention: Keeps the coating looking fresh and vibrant.

- Abrasion resistance: Protects against vehicle traffic and dropped tools.

- Chemical resistance: Shields the surface from oil, gasoline, and common household cleaners.

Additionally, check for coatings certified by ASTM standards for quality assurance. Features like thickness, slip resistance, and gloss level also play a role in achieving the best results.

The Advantage of Polyurea and Polyaspartic Systems

Polyurea and polyaspartic coatings are a step above traditional epoxy. These advanced systems offer excellent UV stability, meaning they won’t yellow or degrade in direct sunlight. They also cure quickly – within hours – making them ideal for minimizing downtime. Unlike epoxy, they handle temperature fluctuations, hot tires, and heavy traffic with ease, making them a reliable choice for long-term performance.

Croc Coatings’ Penntek Evolution System

For a high-performance solution, Croc Coatings provides the Penntek Evolution system, a top-tier industrial-grade coating designed for garages exposed to UV rays. This system is 4x more durable than epoxy, offering unmatched strength and UV stability. It can be installed in just one day, and with a lifetime manufacturer’s warranty, it gives homeowners and small business owners peace of mind.

As a Penntek Certified Partner, Croc Coatings serves North Idaho, Spokane, and the Tri-Cities, delivering professional installations tailored to both residential and commercial needs. If you’re looking for a coating that combines UV resistance, quick curing, and long-lasting durability, the Penntek Evolution system is a standout option.

Caring for UV-Resistant Garage Floors

While advanced UV-resistant coatings provide excellent protection, they still need a bit of help to stay in top shape. Routine maintenance plays a key role in keeping your garage floor durable and looking great over time. With a few simple habits, you can ensure your floor remains in excellent condition for years to come.

Regular Cleaning Practices

Keep your garage floor clean by sweeping or using a dust mop every week to remove dirt and debris that could scratch the surface. For a deeper clean, use a damp mop with warm water and a mild, pH-neutral detergent. Avoid harsh chemicals, ammonia-based cleaners, or abrasive tools, as they can damage the coating’s finish. Understanding the causes of concrete coating failures can help you avoid common maintenance mistakes. If you spill oil, gasoline, or antifreeze, clean it up right away to prevent stains from setting in.

Avoiding Heat Buildup

Dark rubber mats and tires can absorb up to 80–90% of sunlight, creating hotspots that may reach temperatures as high as 140°F. These hotspots can cause uneven expansion, putting stress on the floor’s coating. To prevent this, avoid leaving black mats, dark storage bins, or spare tires sitting in the same sunny spot for too long. Instead, use light-colored or woven polypropylene mats that allow airflow underneath, or move items around periodically to let the floor cool evenly. When temperatures climb above 90°F during the summer, open your garage door to improve ventilation and help disperse heat, reducing thermal stress on the coating. Keeping an eye on these conditions can also help you spot early signs of wear and tear.

Signs You Need Recoating or Repair

Be on the lookout for signs your garage floor needs a new coating, such as peeling, bubbling, lifting, micro-cracking, or a noticeable loss of gloss. These are clear indicators of adhesion problems or thermal stress. Catching these signs early allows you to address them before they lead to more serious damage, helping maintain the protective qualities of your garage floor.

Conclusion

UV-resistant coatings play a critical role in protecting garage floors from sun damage. Unlike traditional epoxy, which tends to yellow, fade, and peel when exposed to sunlight through garage doors or windows, polyurea and polyaspartic systems stay colorfast and stable for years. Beyond appearance, UV damage can lead to increased maintenance needs and reduced durability.

Comparing polyurea vs. epoxy and switching to UV-stable systems addresses these challenges effectively. These advanced coatings offer better heat resistance, faster curing times, and longer-lasting performance. Professional installers often favor polyurea and polyaspartic coatings because they preserve both the protective qualities and the visual appeal of garage floors, even in demanding conditions. There are many benefits of polyurea that make it a superior choice for these environments. This not only safeguards the floor’s integrity but also helps maintain your home’s value.

Croc Coatings brings this advanced UV-stable technology to homeowners in North Idaho, Eastern Washington, Spokane, and the Tri-Cities. As a Penntek™ Certified Partner, they install the Penntek Evolution industrial coating system, which is designed to be four times more durable than epoxy and comes with a lifetime manufacturer’s warranty. This ensures long-term protection and peace of mind for your garage floor.

FAQs

Why should I choose UV-resistant coatings instead of standard epoxy for my garage floor?

UV-resistant coatings are crafted to endure the harsh effects of sunlight, providing strong protection against fading, chalking, and surface wear caused by UV rays. In contrast, standard epoxy tends to discolor and break down over time when exposed to sunlight, making it a less reliable choice for bright or outdoor spaces.

Choosing UV-resistant coatings helps preserve the color, durability, and finish of your garage floor, ensuring it stays in great shape even in areas with heavy sun exposure.

How do UV rays damage concrete and standard garage floor coatings?

UV rays can wreak havoc on concrete surfaces, breaking them down over time and causing problems like cracking, spalling, and discoloration. Many standard coatings just aren’t built to handle prolonged UV exposure, which often leads to issues like chalking, peeling, or losing adhesion. This not only diminishes the look of your garage floor but also compromises its protective layer.

That’s where UV-resistant coatings come in. These specialized coatings are designed to shield your garage floor from harmful UV rays, preserving its surface, maintaining its strength, and even extending its lifespan. Choosing a high-quality UV-resistant coating ensures your garage floor stays durable and looks great for years to come.

How can I maintain UV-resistant coatings to keep my garage floor looking great?

To maintain your UV-resistant garage floor coating in great shape, make it a habit to clean the surface regularly with mild soap and water. Steer clear of harsh chemicals, as they can harm the coating. If spills occur, clean them up quickly to avoid stains or discoloration.

It’s also a good idea to occasionally inspect the floor for signs of wear or damage. When necessary, apply a UV-protective topcoat to preserve its durability and shield it from further harm. With these straightforward steps, you can prolong the life of your garage floor and keep it looking its best for years.

Related Blog Posts

- What Is UV Stability in Concrete Coatings?

- UV-Resistant Garage Floor Coatings: What to Know

- Why UV Stability Matters for Garage Floors

- How UV Rays Affect Concrete Coating Colors