Textured Coatings for Harsh Climates

January 30, 2026

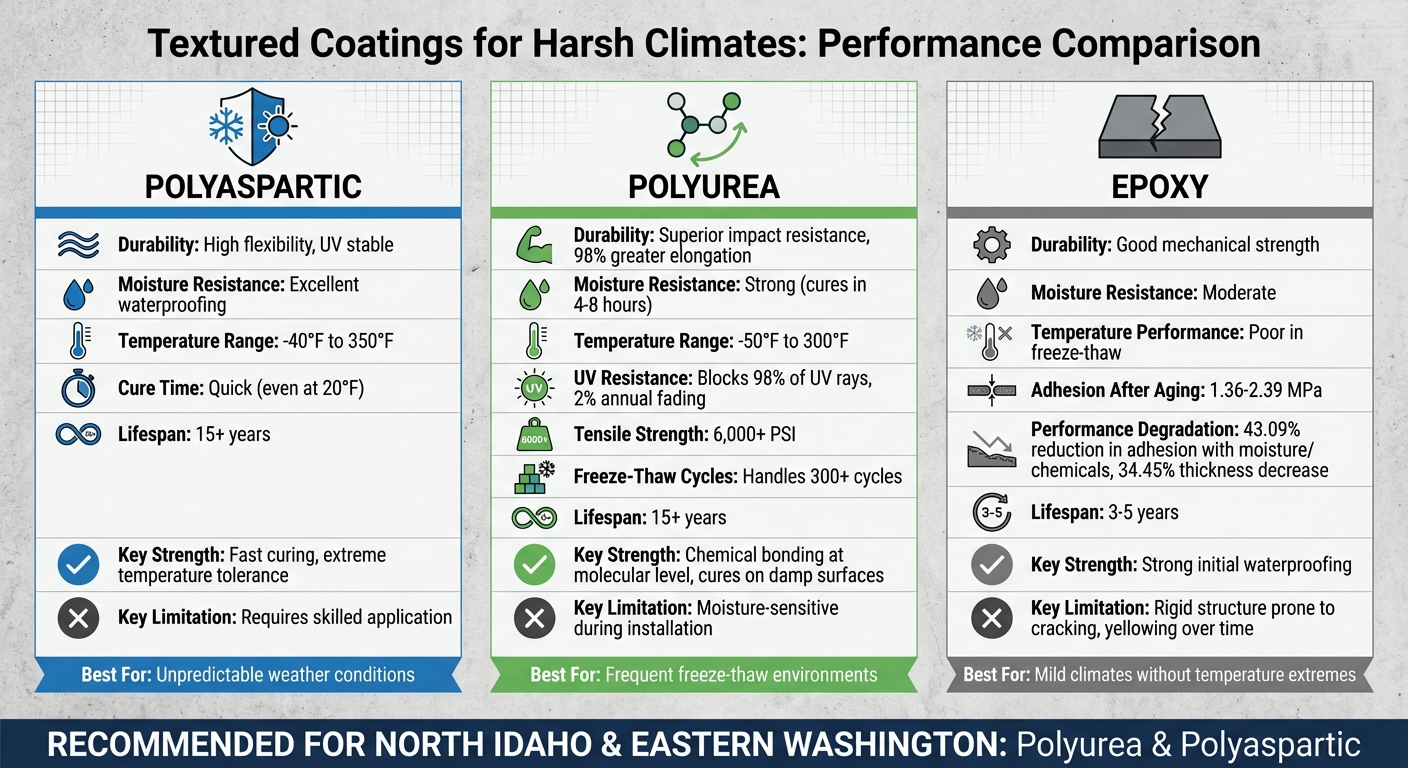

When protecting concrete surfaces in areas with extreme weather, the right coating matters. Freeze-thaw cycles, heavy rain, and UV exposure can cause cracking, peeling, and costly repairs. This article compares three types of coatings – polyaspartic, polyurea-based, and epoxy textured coatings – to determine which performs best under harsh conditions. Here’s the key takeaway:

- Polyaspartic coatings: Quick curing, highly flexible, and great for temperature extremes, but require skill to apply.

- Polyurea coatings: Strong chemical bond, excellent flexibility, and UV resistance, with fast curing even on damp surfaces.

- Epoxy coatings: Durable and waterproof, but rigid, making them less reliable in freeze-thaw conditions.

Quick Comparison:

| Coating Type | Durability | Moisture Resistance | Temperature Range | Key Limitation |

|---|---|---|---|---|

| Polyaspartic | High flexibility, UV stable | Excellent | -40°F to 350°F | Fast curing requires skill |

| Polyurea | Superior impact resistance | Strong | –50°F to 300°F | Moisture-sensitive during install |

| Epoxy | Good mechanical strength | Moderate | Poor in freeze-thaw | Rigid, prone to cracking |

For areas like North Idaho and Eastern Washington, polyurea and polyaspartic coatings are better options due to their flexibility and long-term durability. While more expensive upfront, they provide longer-lasting protection, saving money on repairs in the long run.

Comparison of Polyaspartic, Polyurea, and Epoxy Coatings for Harsh Climates

1. Polyaspartic Textured Coatings

Durability in Harsh Climates

Polyaspartic coatings are built to handle extreme weather. They cure quickly – even in temperatures as low as 20°F – reducing the chance of contamination and creating a solid bond. This makes them perfect for areas like North Idaho and Eastern Washington, where weather can be unpredictable. Their flexibility is another standout feature, allowing them to expand and contract with concrete during temperature swings, from freezing cold to over 90°F. This adaptability helps prevent cracking and peeling, ensuring long-lasting protection.

Resistance to Moisture and Chemicals

These coatings act as a tough, waterproof shield, keeping water out – a critical feature in places prone to heavy rain or freeze-thaw cycles. Their dense structure also holds up against de-icing salts, automotive fluids, and household chemicals, stopping them from breaking down the concrete. Paired with their ability to handle temperature changes, this makes polyaspartic coatings a smart choice for challenging environments.

Performance in Temperature Fluctuations

Polyaspartic coatings can handle a wide temperature range, from -40°F to 300°F, without losing their strength. They stay flexible in freezing cold, resist softening in extreme heat, and even stand up to UV damage from sunlight. This durability ensures they protect outdoor surfaces year-round, outperforming many other types of coatings in extreme conditions.

sbb-itb-a0e5ae3

2. Polyurea-Based Textured Coatings

Durability in Harsh Climates

Polyurea coatings form a strong chemical bond with concrete, creating a connection that goes beyond the surface. Instead of just filling surface pores, polyurea penetrates deeply and reacts with the moisture naturally present in concrete. This reaction creates covalent urea linkages. As Croc Coatings explains:

This reaction forms urea linkages, which are covalent bonds that create a molecular-level attachment between the coating and the concrete.

This bond is incredibly durable, reducing the chances of chipping, peeling, or delamination, even under heavy use or extreme weather. The coating’s flexibility also helps it withstand temperature changes without cracking. Additionally, its rapid reaction with environmental moisture makes it a practical choice for damp conditions.

Resistance to Moisture and Chemicals

Polyurea coatings stand out because they don’t require a perfectly dry surface to cure. They can react with ambient moisture and set in just 4–8 hours, making them ideal for areas with high humidity or frequent rain. This makes them especially useful in regions like North Idaho and Eastern Washington, where moisture levels can vary. Unlike coatings that take 24–72 hours to cure, polyurea significantly reduces the risk of weather-related contamination during application.

Performance in Temperature Fluctuations

Polyurea coatings are engineered to handle a wide temperature range, from –50°F to 300°F, without losing their strength or flexibility. For instance, the Penntek Evolution system boasts a tensile strength of over 6,000 PSI and blocks 98% of UV rays. This means the coating experiences minimal fading – about 2% annually – and retains over 90% of its color after five years. In comparison, many alternatives begin yellowing within just 18 months, highlighting polyurea’s superior long-term performance.

3. Epoxy Textured Coatings

Durability in Harsh Climates

Epoxy coatings, while known for their toughness, face limitations in extreme climates due to their rigidity. They provide strong mechanical resistance and excellent waterproofing for concrete, forming a barrier against chemicals and erosion. However, they don’t handle freeze-thaw cycles well. In regions like North Idaho and Eastern Washington, where temperatures fluctuate drastically, epoxy’s stiffness under freezing conditions can allow moisture to seep into microcracks. This moisture can then freeze and expand, leading to fractures. Over time, this vulnerability makes epoxy coatings less reliable in areas with repeated freeze-thaw cycles.

Resistance to Moisture and Chemicals

Epoxy coatings are designed to resist chloride penetration and bridge small cracks effectively. But when exposed to combined stressors, such as moisture and chemicals, their performance declines. For example, testing with a 7% urea solution and freeze-thaw cycles showed a 43.09% reduction in pull-off adhesion, a 34.45% decrease in coating thickness (compared to a 23.51% reduction in water-only conditions), and a 146.73% increase in water absorption. A study published in Scientific Reports noted:

The presence of moisture has the potential to weaken the mechanical properties of the epoxy, leading to degradation or failure and ultimately resulting in a reduction in adhesion strength.

This highlights the challenges epoxy coatings face when exposed to both moisture and chemical environments simultaneously.

Performance in Temperature Fluctuations

Another challenge for epoxy coatings is their inability to handle extreme temperature swings. In climates with freezing winters and hot summers, the constant expansion and contraction of materials can weaken the coating. When combined with chemical exposure, these thermal cycles can lead to adhesive failure and lower bond strength. After undergoing aging tests, the adhesion strength of epoxy coatings typically falls within a range of 1.36 to 2.39 MPa. This reduced performance underscores their limited suitability for environments with significant temperature fluctuations.

Applying Epoxies in Cold Temperatures

Advantages and Disadvantages

When it comes to coatings for harsh climates, each option has its own strengths and weaknesses. Understanding these trade-offs is key to choosing the right one for the job.

Polyaspartic coatings stand out for their excellent UV resistance and quick curing time, making them a go-to for projects on a tight schedule. However, their fast curing process demands a skilled hand for proper application.

Polyurea-based coatings shine in flexibility and impact resistance, making them highly effective during freeze-thaw cycles without cracking. They also bond exceptionally well and can handle a wide range of temperatures. That said, they are moisture-sensitive during installation and require specialized tools to apply.

Epoxy coatings offer decent durability and can improve slip resistance while enhancing bond strength. They provide moderate protection against moisture but tend to be more rigid, which makes them less reliable in freeze-thaw environments.

Here’s a quick comparison of their attributes and limitations:

| Coating Type | Durability | Moisture Resistance | Temperature Performance | Key Limitation |

|---|---|---|---|---|

| Polyaspartic | High flexibility, UV stable | Excellent waterproofing | –40°F to 350°F range | Fast cure requires skill |

| Polyurea | Superior impact resistance | Strong when properly applied | Handles 300+ freeze-thaw cycles | Moisture-sensitive during install |

| Epoxy | Good mechanical strength | Moderate | Poor in freeze-thaw conditions | Rigid, prone to cracking |

For areas like North Idaho and Eastern Washington, where freeze-thaw cycles are frequent, coatings that remain flexible and maintain strong adhesion over time are crucial for enduring performance.

Conclusion

Polyurea and polyaspartic coatings have proven to be a better choice than epoxy for harsh climates. Their ability to flex, resist UV damage, and compare polyurea and epoxy for extreme temperatures makes them ideal for challenging conditions in areas like North Idaho and Eastern Washington.

One standout feature of polyurea is its impressive 98% greater elongation, allowing it to adapt to concrete’s movement during freeze-thaw cycles. This flexibility also supports its excellent thermal performance, enduring stable heat up to 266°F and short bursts up to 430°F. For outdoor surfaces exposed to sunlight, polyurea resists UV-induced yellowing, unlike epoxy, which tends to degrade over time.

"While polyurea is more expensive than epoxy, you pay for the longevity and durability that will give you your money’s worth." – Rebecca Harrell, Content Writer, Southwest Exteriors

The cost may be higher upfront, but the long-term cost benefits of polyurea are clear. With a lifespan exceeding 15 years, polyurea far outlasts epoxy’s 3 to 5-year service life. When professionally installed, polyurea coatings offer decades of reliable performance, free from the cracking, yellowing, or peeling that epoxy often experiences in tough environments.

For homeowners in North Idaho and Eastern Washington, polyurea-based systems are a solid choice for surfaces like patios, pool decks, driveways, and garage floors. Working with Croc Coatings ensures your surfaces are equipped to handle even the most demanding weather conditions.

FAQs

Why are polyurea coatings a great choice for areas with frequent freeze-thaw cycles?

Polyurea coatings are a smart option for areas that deal with frequent freeze-thaw cycles. Why? Because they stay flexible even in cold temperatures, which helps them resist cracking and peeling when temperatures swing rapidly. This flexibility makes a big difference in preventing damage caused by constant freezing and thawing.

On top of that, polyurea forms a strong, waterproof shield that keeps moisture out. Since water infiltration is a leading cause of freeze-thaw damage, this protective barrier is crucial. These coatings are built to handle tough weather, making them perfect for surfaces like garage floors, patios, and pool decks in challenging climates. Their ability to hold up through temperature shifts means they stay effective and reliable over time.

What makes polyaspartic coatings better than epoxy for UV resistance?

Polyaspartic coatings stand out for their UV resistance, making them a great option for spaces exposed to sunlight. Unlike epoxy, which tends to yellow, fade, or lose its luster when subjected to UV rays, polyaspartic coatings stay durable and retain their look even under intense sunlight.

This durability and visual appeal make them perfect for outdoor areas like patios, pool decks, or any space where both performance and appearance matter over time.

Why is it important to have polyaspartic coatings installed by professionals?

Professional installation of polyaspartic coatings plays a key role in achieving a high-quality, durable finish. Proper surface preparation, accurate material mixing, and applying the coating under the right conditions are critical to avoiding problems like bubbling, poor adhesion, or early failures.

Because polyaspartic coatings cure quickly and are sensitive to temperature and moisture, they require skilled handling to ensure they perform as intended. Relying on experts not only helps extend the life of your surfaces but also ensures they can handle tough conditions and heavy use over time. It’s an investment in both quality and longevity.

Related Blog Posts

- Concrete Coatings for Harsh Climates

- Weatherproof Patio Coatings for Harsh Climates

- Polyurea vs. Epoxy: Best for Humid Areas

- Impact Resistance in Harsh Climates: Polyurea Benefits