Garage Floors in High-Traffic Homes: Best Coatings

December 25, 2025

Looking for a garage floor that can handle heavy use? Here’s how to choose a garage floor coating that fits your needs:

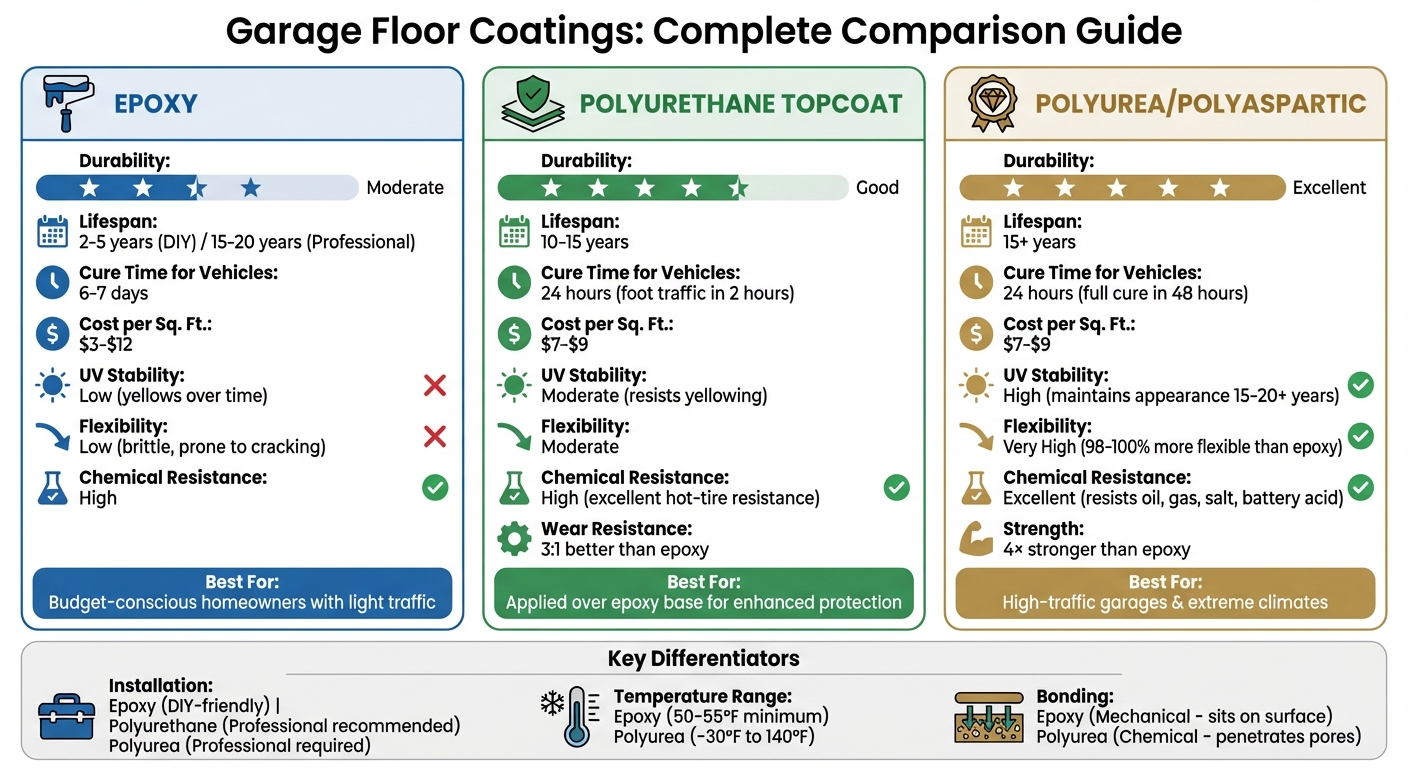

- Epoxy coatings are affordable, durable, and resist chemicals but can crack over time and require 6–7 days to cure for vehicles. Lifespan: 2–5 years (up to 15–20 years professionally applied).

- Polyurethane topcoats add durability over epoxy, resist UV yellowing, and allow quicker use (24 hours for vehicles) but are prone to peeling if applied too thinly.

- Polyurea and polyaspartic coatings are the strongest option, lasting 15+ years with high flexibility, chemical resistance, and UV stability. They cure in 24 hours but require professional installation.

Quick Comparison

| Feature | Epoxy | Polyurethane | Polyurea/Polyaspartic |

|---|---|---|---|

| Durability | Moderate | Good | Excellent |

| Lifespan | 2–5 years (DIY) | 10–15 years | 15+ years |

| Cure Time (Vehicle) | 6–7 days | 24 hours | 24 hours |

| Cost per Sq. Ft. | $3–$12 | $7–$9 | $7–$9 |

| UV Stability | Low (yellows) | Moderate | High |

For tough conditions or extreme climates, polyurea coatings like Croc Coatings’ Penntek Evolution system stand out. They bond deeply with concrete, resist cracking, and come with a lifetime warranty. While costlier upfront, their durability and low maintenance make them a strong long-term choice.

Garage Floor Coating Comparison: Epoxy vs Polyurethane vs Polyurea

Which Concrete Coating Should You Use? | FULL COMPARISON

For more expert advice on maintaining your floors, explore our concrete floor maintenance guide.

1. Epoxy Coatings

Epoxy coatings are made by combining polymer resins with a polyamine hardener, creating a strong bond with concrete surfaces. The result is a tough, impact-resistant, and nonporous surface that stands up to oils, chemicals, and heavy traffic.

The most durable option is 100% solids epoxy, which cures to leave a thick, wear-resistant layer. When applied professionally, these coatings can last 15 to 20 years. However, DIY kits or lower-grade products often fall short, especially in areas with freeze-thaw cycles, where they may only last 2 to 5 years.

One downside of epoxy, particularly for busy households, is the cure time. You can walk on it after 24 hours, but vehicles need to stay off for 6–7 days, which can be inconvenient. Professional installation costs typically range between $3 and $12 per square foot, with the average garage project costing about $2,342.

Epoxy does have some limitations, especially in extreme environments. Standard formulations can yellow when exposed to sunlight and become brittle over time. This brittleness makes the coating prone to cracking as the underlying concrete expands and contracts. Additionally, the surface can be slippery when wet unless anti-slip solutions like decorative flakes or aluminum oxide are used.

Warranties for epoxy coatings vary, typically ranging from 1 to 2 years in colder climates, though some high-end products offer coverage up to 10 years. Bob Harris from the Decorative Concrete Institute notes:

"For a DIYer or where speed isn’t critical, a 100%-solids epoxy is great for coating garage floors, but it requires two to three days to apply".

Up next, we’ll look at polyurethane topcoat systems, which provide a different mix of durability and faster application.

2. Polyurethane Topcoat Systems

Polyurethane topcoats work differently from epoxy coatings – they don’t adhere directly to bare concrete. Instead, they’re applied as a clear protective layer over an epoxy base coat, combining the thickness and strong adhesion of epoxy with polyurethane’s enhanced surface durability.

One standout feature of polyurethane is its impressive wear resistance. At just 2–3 mils thick, it offers 3:1 wear resistance compared to epoxy. Thanks to its flexibility, polyurethane absorbs impacts without chipping, and its water-clear finish resists UV yellowing, keeping the surface looking pristine over time.

Polyurethane also excels in resisting hot-tire pickup, a common issue where warm tires cause coatings to soften and peel. Unlike epoxy, polyurethane holds up under these conditions and provides better protection against harsh chemicals like methylene chloride, often found in paint strippers. Bob Harris from the Decorative Concrete Institute emphasizes:

"Regardless of the system you use, it’s a good idea to topcoat with a clear polyaspartic aliphatic polyurea. This will give you better chemical resistance, hot tire resistance, and UV stability".

Another advantage is its quicker return-to-service time. Polyaspartic systems, a high-performance type of polyurethane, allow foot traffic in just 2 hours and vehicle traffic within 24 hours. While professional installation costs range from $7 to $9 per square foot – about 20% higher than standard epoxy – these systems can last 15 years or more with proper application. This durability and fast curing make polyurethane ideal for high-traffic areas like garages.

However, it’s worth noting that the glossy finish, while visually appealing, can become slippery when wet. To address this, anti-slip aggregates should be added. Professional expertise is essential for installation, especially since some polyurethane formulations cure in as little as 10 minutes. These characteristics highlight the need for careful consideration when weighing the pros and cons of polyurethane topcoat systems.

sbb-itb-a0e5ae3

3. Polyurea/Polyaspartic Coatings (e.g., Croc Coatings’ Penntek Evolution)

Polyurea and polyaspartic coatings have taken garage floor protection to a whole new level. Unlike epoxy, which forms a mechanical bond that simply sits on the surface of the concrete, polyurea creates a chemical bond that penetrates deep into the concrete’s pores. This difference makes polyurea coatings about four times stronger than traditional epoxy, with a lifespan exceeding 15 years – far outlasting epoxy’s typical 2–5 years. Strength aside, flexibility is another major factor that sets polyurea apart, especially in garages with heavy foot and vehicle traffic.

One standout feature of polyurea is its enhanced flexibility – up to 10 times greater than epoxy. This flexibility allows the coating to move with the concrete as it expands and contracts during temperature changes, significantly reducing the risk of cracks. It also absorbs impacts better, making it less prone to chipping. Plus, it resists "hot-tire pickup", where heated tires can peel lesser coatings off the floor.

Polyurea also shines in its chemical resistance. Its non-porous surface can handle spills from oil, gasoline, antifreeze, road salt, and even battery acid without staining or degrading. Adding a clear polyaspartic topcoat takes things further, boosting both chemical and UV resistance for long-lasting performance.

Another big advantage? The speedy installation process. Croc Coatings’ Penntek Evolution system is a prime example of this efficiency, offering one-day professional installation with a lifetime warranty to back it up. Once applied, the surface is ready for foot traffic in just a few hours and can handle vehicle traffic within 24 hours. Full curing is complete in 48 hours. At a cost of $7 to $9 per square foot, the extended lifespan and minimal maintenance make it a smart investment.

Because of its fast curing times and the precise mixing required, professional installation is a must. Installers use industrial grinders to achieve a Concrete Surface Profile (CSP) of 3–4 and check moisture levels with digital meters before applying the coating. Croc Coatings is so confident in the durability of its Penntek Evolution system that it offers a lifetime warranty for residential use.

Advantages and Disadvantages

Choosing the right floor coating for a high-traffic garage often comes down to weighing the benefits and drawbacks of each option. Every coating type has unique characteristics that affect how well it performs under heavy use.

Epoxy coatings are a budget-friendly option, costing around $3 to $6 per square foot. Their longer pot life makes them easier for DIY projects. However, epoxy is rigid, which can lead to cracking as the concrete beneath it shifts over time. Croc Coatings explains:

"Epoxy keeps curing year after year so as it continues to harden, the movement of the concrete below eventually forces the coating to break free causing peeling, chipping and ultimately failure".

Another drawback is its poor UV resistance, which causes yellowing over time, making it less ideal for garages exposed to sunlight.

Polyurethane topcoat systems provide strong chemical resistance and moderate UV stability. These coatings, however, require up to four days to cure before they can handle vehicle traffic. Their thinner application can also make them more prone to peeling under heavy use.

Polyurea and polyaspartic coatings, like Croc Coatings’ Penntek Evolution system, offer significant advantages. They bond deeply with the concrete’s pores rather than just sitting on the surface, making them about four times stronger than epoxy and up to 98–100% more flexible. This flexibility allows them to move with the concrete without cracking. They also excel in chemical resistance, hot tire resistance, and UV stability, making them a top choice for demanding environments. The trade-offs? A higher upfront cost of $7 to $9 per square foot and the need for professional installation due to their short pot life of just 10–12 minutes.

Here’s a quick comparison of key features across these systems:

| Feature | Epoxy | Polyurethane | Polyurea/Polyaspartic |

|---|---|---|---|

| Wear Resistance | Moderate; prone to chipping/cracking | Good; better than epoxy but thinly applied | Excellent; 4× stronger than epoxy |

| Chemical Resistance | High (resists oil, gas, and household chemicals) | High (commonly used as a protective topcoat) | Excellent; resists salts, gases, and hot tire pickup |

| Cure Time (Vehicle) | About 7 days | Up to 4 days | 24–96 hours |

| Expected Lifespan | 2–5 years | Variable; may peel if too thin | 15+ years |

| UV Stability | Low (yellows or fades over time) | Moderate to high | High (especially with a polyaspartic topcoat) |

| Flexibility | Low (brittle) | Moderate | Very high (98–100% more flexible than epoxy) |

For garages exposed to direct sunlight, polyaspartic finishes stand out by maintaining their appearance for 15 to 20+ years, unlike epoxy, which tends to yellow and chalk over time. Additionally, polyaspartic coatings can cure in temperatures ranging from –30°F to 140°F, whereas epoxy requires a minimum of 50–55°F, making polyaspartic systems ideal for year-round installation in a variety of climates.

Conclusion

When it comes to choosing the best garage floor coating, factors like traffic load and local climate play a big role. For homeowners on a budget who experience light to moderate traffic, standard epoxy might be a good starting point. However, if your garage faces heavy vehicle traffic or you’re in a region with harsh winters and freeze-thaw cycles – like North Idaho or Eastern Washington – polyurea coatings are a smarter choice. Thanks to their flexibility, polyurea coatings move with the concrete, preventing cracks and peeling, and provide a durable, low-maintenance option.

In cold climates, DIY epoxy kits often fall short. Areas like Spokane, Coeur d’Alene, and the Tri-Cities see extreme temperature swings, and these kits lack the flexibility to handle such conditions. A professional polyurea system, such as the Penntek Evolution, offers advanced bonding technology for better durability.

For garages exposed to direct sunlight, UV stability is another key factor. While epoxy coatings can yellow within a few years, polyaspartic topcoats maintain their appearance for 15–20 years or more. If your garage endures daily hot-tire exposure or other tough conditions, polyurea coatings stand up to the challenge with superior resistance.

For homeowners seeking a trusted solution, Croc Coatings is a top choice in North Idaho (serving Post Falls, Coeur d’Alene, Rathdrum, and Sandpoint) and Eastern Washington (including Spokane and the Tri-Cities: Richland, Pasco, and Kennewick). As a Penntek Certified Partner, Croc Coatings has completed over 1,000 installations and earned 300+ five-star reviews. They provide one-day installations, a lifetime manufacturer’s warranty, and use industrial grinders to achieve the ideal Concrete Surface Profile (CSP) of 3–4, ensuring strong adhesion and long-lasting results.

If you’re looking for a garage floor that stays free from peeling, chipping, or fading for 15+ years, Croc Coatings can help. Their Penntek Evolution system is specifically designed to handle the tough conditions of the Pacific Northwest. Contact them for a free in-home estimate and see how they can transform your garage floor.

FAQs

What makes polyurea coatings better than epoxy for garage floors?

Polyurea coatings stand out for their exceptional durability, flexibility, and long-lasting performance when compared to epoxy. One of their biggest advantages is the fast curing time – often just a matter of minutes – making them a practical choice for areas that see a lot of activity. On top of that, polyurea offers strong resistance to UV rays, chemicals, and abrasions, helping your garage floor stay in great shape both in appearance and functionality.

Another key benefit is how well polyurea adheres to concrete surfaces. This strong bond significantly reduces the chances of peeling or cracking over time. For homes with heavy foot traffic or frequent vehicle use, polyurea coatings are a reliable, low-maintenance option built to withstand the demands of daily life.

How does the installation process impact the durability of garage floor coatings?

The installation process is a key factor in how long a garage floor coating will hold up over time. Properly preparing the surface – like thoroughly cleaning and repairing the concrete – lays the groundwork for the coating to bond securely. When done by professionals, this process can extend the coating’s lifespan to 15 years or even longer.

However, cutting corners during preparation or rushing the installation can lead to problems like peeling or cracking, which drastically shorten the coating’s durability. Choosing a high-quality installation process is crucial if you want a floor that stands up to wear and tear for years to come.

What should I look for in a garage floor coating for extreme weather conditions?

When selecting a garage floor coating for regions with extreme weather – think scorching summers, freezing winters, or constant temperature swings – prioritize durability and the ability to handle stress. You’ll want a coating that can endure expansion and contraction without cracking. Polyurea-based systems, like the Penntek Evolution, are specifically engineered to survive freeze-thaw cycles and heavy use.

Another important factor is UV resistance. This prevents the surface from yellowing or deteriorating under strong sunlight. Additionally, choose coatings with chemical and moisture resistance to guard against damage from road salt, oil spills, and water, which can gradually wear down your concrete. And don’t forget to weigh the lifespan and maintenance needs – polyurea coatings can last 15 years or more, often outliving traditional epoxy, which might require replacement every 3–5 years.

For homeowners in areas like North Idaho, Spokane, and the Tri-Cities, Croc Coatings specializes in high-performance solutions built for these tough conditions. Their Penntek Evolution system provides outstanding durability, UV protection, and resistance to chemicals, all with the convenience of a one-day installation and a lifetime warranty. Curious about the process? Check out their YouTube channel for a behind-the-scenes look!

Related Blog Posts

- Epoxy Alternatives: Price Comparison 2025

- Polyurea vs. Epoxy: Eco-Friendly Garage Floor Options

- Top 3 Benefits of Polyurea for Garage Floors

- Short-Term vs Long-Term Costs of Garage Floor Coatings