Custom Garage Cabinets: Installation Tips for Beginners

December 14, 2025

Are you tired of a cluttered garage? Installing custom cabinets can help you organize tools, equipment, and seasonal items while maximizing wall space. This guide walks you through the process, from gathering tools to mounting cabinets securely. Key steps include:

- Preparation: Measure your garage walls, locate studs, and plan a layout.

- Assembly: Cut plywood panels, drill pocket holes, and construct sturdy frames.

- Installation: Secure cabinets to the wall using studs and lag screws.

- Finishing Touches: Add shelves, doors, and protective coatings for durability.

For a professional look without the hassle, companies like Croc Coatings offer one-day installations with eco-friendly materials and lifetime warranties. Whether you DIY or hire help, a well-organized garage is within reach.

Installing Garage Wall Cabinets | Garage Organization Episode 4

Tools and Materials You’ll Need

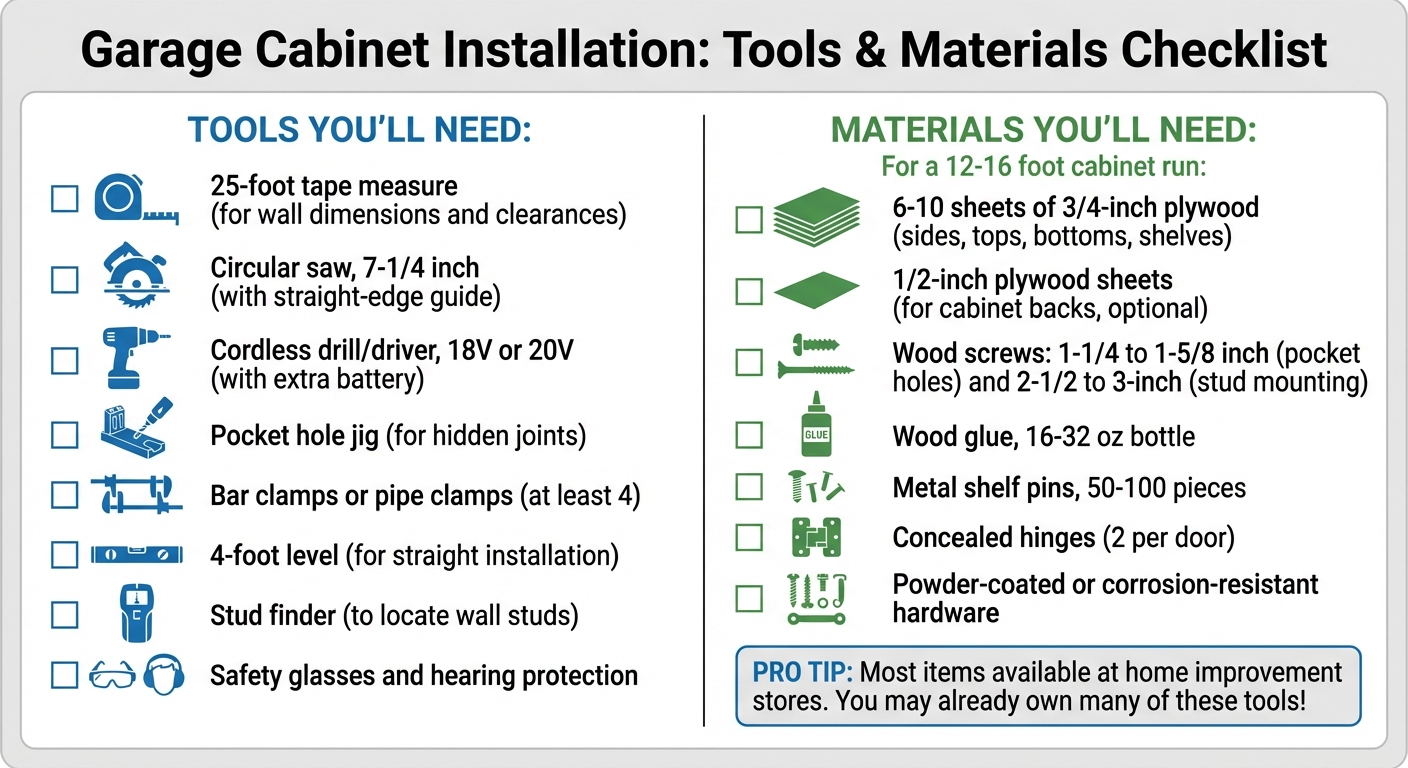

Essential Tools and Materials Checklist for DIY Garage Cabinet Installation

Before diving into cutting or drilling, it’s a smart move to gather everything you’ll need in one place. This way, you won’t have to pause mid-project to hunt down supplies. You can find most of the tools and materials for garage cabinets at big-box home improvement stores across the U.S., and chances are, you already have some of the tools at home.

Tools You’ll Need

Start with a 25-foot tape measure to check wall dimensions, cabinet heights, and clearances around doors or outlets. For cutting plywood panels to size, a circular saw (7-1/4 inch is standard) is essential – pair it with a straight-edge guide for clean, accurate cuts. A cordless drill/driver (18V or 20V) will handle drilling pilot holes and driving screws into plywood and studs. Keep an extra battery handy to avoid interruptions.

A pocket hole jig is a great tool for creating strong, hidden joints in cabinet frames, especially for beginners who want to skip complex joinery. To keep panels square while gluing or screwing, use bar clamps or pipe clamps (at least four). A 4-foot level ensures your ledger boards and cabinets are perfectly straight, preventing doors from swinging open on their own. A stud finder will help you locate wall studs, ensuring secure mounting. And, of course, don’t forget safety glasses and hearing protection for cutting and drilling tasks.

Materials You’ll Need

For a 12–16 foot cabinet run in a two-car garage, you’ll need six to ten sheets of 3/4-inch plywood for the sides, tops, bottoms, and shelves. Plywood is a better choice than MDF or particleboard because it’s stronger and resists moisture – important for garage conditions. If you prefer, you can also pick up a few sheets of 1/2-inch plywood for cabinet backs instead of hardboard.

You’ll need wood screws in a couple of sizes: 1-1/4 to 1-5/8 inch coarse-thread screws for pocket holes and 2-1/2 to 3-inch construction screws for attaching cabinets to studs. Add a 16–32 oz bottle of wood glue for structural joints, along with 50–100 metal shelf pins for adjustable shelving. For cabinet doors, grab concealed hinges (two per door). To withstand the garage environment – moisture, temperature changes, and even road salt – opt for powder-coated or corrosion-resistant hardware like hinges, pulls, and mounting screws. These finishes ensure your cabinets stay functional and durable for years, much like the high-quality systems offered by companies such as Croc Coatings, known for pairing custom cabinets with industrial-grade floor coatings.

Once your tools and materials are ready, you can move on to precise measurements and layout planning.

Taking Measurements and Planning Your Layout

Getting precise measurements is key to avoiding expensive mistakes and ensuring your garage cabinets fit perfectly, with doors that close properly and no unsightly gaps. Start by carefully measuring your garage walls and sketching a layout that shows exactly where each cabinet will go. Here’s how you can do it step by step.

Measuring Your Garage Walls

First, clear out the area completely to give yourself room to work. Use a tape measure to record the length of the wall from corner to corner. Then, measure the height from floor to ceiling at three points: the left side, the center, and the right side. Garage floors and walls are rarely perfectly level, so taking multiple measurements helps you identify any uneven spots early on.

Next, grab a stud finder and locate the studs in the wall where you’ll hang your cabinets. In most U.S. garages, studs are spaced 16 inches apart, though some may use 24-inch spacing. Mark the centerline of each stud with a pencil, drawing a vertical line about 12 inches long. For safety, you’ll need each cabinet to be anchored to at least two studs, as some wall-mounted systems can support up to 200 pounds per cabinet when properly installed. Don’t forget to mark the locations of outlets, switches, water heaters, or anything else that could interfere with your cabinet placement.

Drawing Your Cabinet Layout

Now, create a scaled drawing of your wall. Use a ratio like 1/2 inch equals 1 foot to make it easier to visualize. Start by placing the base cabinets. The standard height for these is 36 inches from the floor to the countertop, which matches the height of most workbenches and provides a comfortable working surface for adults.

If you’re including upper cabinets, leave 18 to 24 inches of space between the countertop and the bottom of the upper cabinets. This gives you enough room to work with tools and appliances without feeling cramped. Transfer your stud markings to the drawing and adjust cabinet positions so each one aligns with at least two studs. If a cabinet falls between studs, shift it slightly to the left or right to ensure proper support while maintaining a balanced look.

Be sure to leave a few inches of clearance at corners and near doors to accommodate any irregularities and allow for door swing. Double-check all measurements against the actual wall before you begin assembling or mounting anything. A well-thought-out layout makes the installation process much easier and ensures your cabinets are securely anchored and perfectly positioned.

Assembling the Cabinet Frame

With your garage space optimization layout finalized, it’s time to bring your cabinet to life. This involves cutting panels, drilling pocket holes, and assembling a frame that’s both square and sturdy. Here’s how to do it step by step.

Cutting the Plywood Panels

Start with 3/4-inch plywood, like birch or maple, which is durable, resists warping, and can handle heavy loads. Avoid thinner options like 1/2-inch sheets for the sides, top, and bottom, as they won’t provide the strength needed for garage storage. For a standard cabinet, cut:

- Two side panels: 23.75 inches high by 23.5 inches deep

- Two top and bottom panels: 24 inches wide by 23.5 inches deep

- Shelves (as needed): 23 inches wide by 23.5 inches deep

Wear safety gear, clamp the plywood securely, and mark your cut lines using a square for precision. If you’re using a circular saw, attach a straightedge guide with a 1/4-inch offset to account for the blade width. Adjust the blade depth to slightly exceed the plywood thickness (about 1/4 inch extra). Measure everything twice before cutting, and use a framing square to confirm your corners are perfectly 90°.

Drilling Pocket Holes

Pocket holes create strong, hidden joints and are a great choice for this project. Use a pocket hole jig to drill angled holes, which provide 25–50% more strength than basic butt joints. For 3/4-inch plywood, set your jig to the "1" material thickness setting and use #8 fine-thread screws that are 2.5 inches long. The jig typically drills at a 15-degree angle, which increases screw holding power.

Clamp the jig flush to the end grain of each panel before drilling. Drill two holes for each joint, spacing them 1 to 2 inches apart for even strength. Use the drill’s stop collar to prevent over-drilling, which could cause blowout on the opposite side.

Putting the Frame Together

Begin by dry-fitting the joints with pocket screws. Check that the frame is square by measuring the diagonal lengths – both should match within 1/8 inch. If they don’t, make adjustments until they do.

Once everything aligns, disassemble the frame and apply a thin bead of Titebond II wood glue (about 1/8 inch thick) to all mating surfaces. This glue is water-resistant, making it ideal for garage conditions. Reassemble the frame, inserting screws by hand first. Then, use four to six bar clamps (24 to 36 inches long) to hold the joints securely, rechecking each corner with a framing square as you go.

After 30 minutes, tighten the screws fully and allow the glue to cure for at least one hour. Work on a flat surface to avoid racking, and tighten screws evenly to keep the frame square. Properly assembled, these joints can support more than 200 pounds of static load per cabinet. Once the frame is complete, you’re ready to move on to installing shelves and doors.

sbb-itb-a0e5ae3

Adding Shelves and Doors

Now it’s time to add shelves and doors to make your cabinets functional and polished.

Installing Adjustable Shelves

Adjustable shelves give you the flexibility to adapt your storage as your needs evolve. Start by marking a reference line on each side of the cabinet. Typically, measure about 4 inches up from the bottom and mark where the first row of shelf pin holes will go. Use a level to ensure the marks are perfectly aligned.

To avoid chipping the plywood, apply masking tape where you’ll drill. Clamp a shelf-pin jig or a simple template (with holes spaced 1.25 to 2 inches apart) to the cabinet side. Use a brad-point bit that matches your pin size (commonly 1/4 inch or 5mm) and wrap tape around the bit to act as a depth stop, preventing you from drilling through the cabinet. Drill straight down one column of holes, then reposition the jig to drill the second column. Repeat the process on the opposite side of the cabinet. Keep the holes at least 2 inches from the front edge for added strength.

Adjust the shelf spacing based on what you plan to store – lower shelves are better for heavier items. Once the holes are drilled, vacuum out any debris, then firmly insert shelf pins into four matching-height holes. Place the shelf on the pins, press it into place at each corner, and check that it’s level. If the shelf sags under heavy loads, consider adding a center support or using thicker material before fully loading it.

With the shelves in place, the next step is attaching cabinet doors for a finished, cohesive look.

Mounting Cabinet Doors

Euro-style concealed overlay hinges are a great choice for beginners because they’re easy to adjust and keep the hardware hidden for a sleek appearance. For doors up to 36 inches tall, use two hinges; for taller or heavier doors, opt for three. Start by marking hinge cup locations about 3–4 inches from the top and bottom of the door. Lay the door flat and drill the cup recess using a 35mm Forstner bit. Drill carefully, checking frequently to avoid going through the door. Then pre-drill pilot holes and attach the hinges to the door.

Inside the cabinet, mark where the mounting plates will go – these should align with the hinge cup locations. Pre-drill holes and screw the mounting plates to the cabinet sides, ensuring they’re level. Clip the hinges onto the mounting plates, tighten the main screws, but leave the adjustment screws loose for now.

To maintain consistent gaps between doors and the frame, use playing cards or 1/8-inch spacers at the top and sides. Hang one door first as a reference, adjusting it to be square and level using the hinge’s three adjustment screws: side-to-side, in/out, and up/down. Once the first door is properly aligned, hang the neighboring doors and adjust their tops and gaps to match. Step back to check that horizontal lines are straight and vertical gaps are even. When everything looks right, tighten all screws securely.

Mounting Cabinets to the Wall

With your cabinets assembled and doors in place, it’s time to secure them to the wall. This step is essential – properly mounted cabinets can support 150-300 lbs when fully loaded, provided they’re anchored correctly to wall studs. Skipping critical steps can result in sagging or even a complete collapse.

Finding Studs and Setting Up a Ledger Board

Start by locating the wall studs using a stud finder, marking the center of each one. You’ll need at least two studs to support each cabinet section. To confirm your marks, tap the wall – studs will sound solid, while the gaps between them will sound hollow.

Next, install a ledger board as temporary support to hold the cabinets level during installation. A sturdy 1×4 or 2×4 piece of lumber works well for this. Measure up from the floor to the height where the bottom of the cabinets will sit (typically around 54 inches for comfortable access) and mark this height at several points across the wall. Use a 4-foot level to connect these marks with a perfectly horizontal line. Even a 1/8-inch difference over a long distance can result in uneven cabinets.

Align the ledger board with this line and pre-drill pilot holes at each stud location. Secure the board with 3-inch wood screws, anchoring it to at least every other stud. This provides a stable base that can hold over 200 lbs per cabinet section. Once the cabinets are permanently mounted, you can remove the ledger board. With this support in place, you’re ready to attach the cabinets.

Anchoring Cabinets with Lag Screws

With the ledger board installed, it’s time to anchor the cabinets. Lift and rest each cabinet on the board. If your walls are uneven, use shims (no more than 1/8 inch thick) to fill any gaps. This prevents stress on the cabinet joints and ensures the doors align and close properly.

Check that the cabinet is level and plumb using a level tool, adjusting with shims as needed. Once positioned correctly, pre-drill through the cabinet’s back rail into the studs. Secure the cabinet to at least two studs using lag screws (typically 1/4-inch in diameter and 3 to 4 inches long). When installing adjacent cabinets, clamp them together and secure them as a unit before anchoring them to the wall. This method ensures the cabinets remain stable, even when fully loaded.

After all screws are tightened, test the cabinet’s stability by gently pushing on the front – it should stay firm without any movement. Trim any excess shim material flush with the cabinet edges using a utility knife. Once all cabinets are secure, you can remove the ledger board. Keep in mind, cabinets should never be mounted to drywall alone – they must be attached to studs or secured with heavy-duty toggle bolts rated for at least 500 lbs as a backup. Always wear proper safety gear during installation.

For step-by-step video tutorials on securely mounting your cabinets, visit the Croc Coatings YouTube channel.

Finishing Touches and Custom Options

With your cabinets securely mounted, it’s time to focus on protecting them and adding practical features. These final steps not only enhance their durability but also improve their functionality and ease of use.

Applying a Protective Finish

A polycrylic finish is a great choice, especially for beginners. It’s easy to apply, dries quickly, and creates a clear, durable shield against moisture, dust, and chemicals. Start by lightly sanding all surfaces with 220-grit sandpaper, then wipe them clean with a tack cloth. Use a synthetic brush to apply the first coat, following the direction of the wood grain. Each coat dries in about two hours.

Once the first coat is dry, sand lightly again, clean the surface, and apply a second coat. For the best results, apply 2–3 thin coats. This process makes your cabinets significantly more resistant to wear and tear, allowing you to clean them effortlessly with a damp cloth and mild soap. Let the finish cure for 24 hours before loading the cabinets with heavy items to ensure maximum durability.

Adding Custom Features

Customizing your cabinets can make them more efficient and tailored to your needs. For example, dowel storage is an excellent solution for organizing vertical tools. To create this, drill 1-inch holes spaced 4–6 inches apart into the cabinet’s side panels using a Forstner bit. Insert 18-inch wooden dowels, securing them with wood glue. This simple upgrade can improve space efficiency by up to 30% and hold as many as 20 items per cabinet section.

For better lighting, consider installing under-shelf LED strips. Opt for a 12V strip that’s 16.4 feet long and produces 1,200 lumens. Use 3M adhesive tape to mount the lights, connect them to a plug-in transformer hidden at the top of the cabinet, and add a motion-sensor switch for automatic activation. This setup takes less than an hour to install and uses less than 20 watts of power.

Another useful addition is a pull-out pegboard mounted on drawer slides for extra tool storage. This feature makes accessing tools easy and keeps everything organized. For detailed installation instructions, check out the Croc Coatings YouTube channel for helpful guides.

Conclusion

Every step in the process of installing garage cabinets plays a crucial role in ensuring a smooth and functional setup. From precise planning to the final installation, attention to detail helps avoid common problems like misaligned doors, sagging shelves, or unstable mounting.

The key to success lies in accurate measurements, thoughtful planning, and consistently checking for level alignment. Start small – tackling just one cabinet section can help you get the hang of things before diving into a full garage transformation.

If any part of the project feels overwhelming, there’s no shame in combining your DIY efforts with professional expertise. For those in North Idaho and Eastern Washington, Croc Coatings offers a one-day installation service backed by a lifetime warranty, providing a stress-free way to achieve a polished, professional finish.

FAQs

What tools do I need to install custom garage cabinets?

To set up custom garage cabinets, make sure you have a few key tools ready: a hammer, screwdriver, level, drill, measuring tape, stud finder, pencil, safety goggles, and gloves. These will help you measure precisely, mount the cabinets securely, and stay safe while working.

Using the proper tools not only simplifies the process but also helps achieve a polished and well-aligned finish. Be sure to double-check your measurements and rely on the level to keep everything straight and looking neat.

What’s the best way to securely install garage cabinets on the wall?

To install garage cabinets securely, begin by finding the wall studs using a stud finder – this will provide a sturdy anchor point. Opt for heavy-duty screws or wall anchors suited to the cabinet’s weight and material. Before securing the cabinets, use a spirit level to ensure they are perfectly aligned. These precautions will help keep the cabinets stable and prevent long-term wear or damage.

What are the best materials for durable garage cabinets?

When it comes to sturdy garage cabinets, wood, metal, and high-quality composite materials stand out as top contenders. Among wood options, plywood and MDF (medium-density fiberboard) are favored for their strength and affordability. On the other hand, steel is a go-to for its long-lasting durability and clean, modern aesthetic.

It’s essential to think about your garage’s conditions when choosing materials. If moisture is a concern, metal or moisture-resistant composite materials can help protect against warping or long-term damage.

Related Blog Posts

- Garage Cabinet Costs: What to Expect

- Custom Garage Cabinets vs DIY Shelves

- How to Budget for Custom Garage Cabinets

- Custom Garage Cabinets vs. Big Box Store Garage Cabinets