Common Problems with Epoxy Garage Floors

January 2, 2026

Epoxy garage floors are durable and stylish but come with challenges that can lead to peeling, bubbling, cracking, yellowing, or slippery surfaces. These issues often stem from poor surface preparation, environmental factors, or improper installation. Up to 80% of epoxy floor failures are linked to inadequate prep, and DIY kits fail at a rate of 30% within two years.

Key Problems and Solutions:

- Peeling: Caused by poor surface prep or trapped moisture. Solution: Proper grinding and curing of concrete.

- Bubbles and Pinholes: Result from outgassing or improper mixing. Solution: Control mixing speed and apply in optimal conditions.

- Cracks: Often due to concrete movement or temperature swings. Solution: Use flexible sealants and ensure proper concrete reinforcement.

- Yellowing: Triggered by UV exposure. Solution: Apply UV-stable topcoats.

- Slippery Surfaces: A safety risk when wet. Solution: Add anti-slip solutions or decorative flakes.

For a more durable alternative, consider polyurea coatings like Penntek Evolution, which bond chemically to concrete, resist UV damage, and include slip-resistant features. These coatings last over 15 years, outperforming epoxy in strength, flexibility, and lifespan.

Problems with an Epoxy Floor Coating (5 Common Problems)

sbb-itb-a0e5ae3

Peeling and Delamination

Peeling is one of the most common – and frustrating – issues with epoxy flooring. It happens when the epoxy coating separates from the concrete surface, often leaving homeowners scratching their heads. What’s worse? It’s almost always avoidable. The floor might look flawless at first, only to start lifting over time, which is one of the pros and cons of epoxy garage floors to consider.

The main reason for peeling is poor surface preparation. For epoxy to adhere properly, the concrete surface needs to be rough and porous, allowing the epoxy to form a solid mechanical bond. If the surface is too smooth, sealed, or contaminated with substances like oil, grease, or even small amounts of brake fluid or tire dressing, the epoxy has nothing to grip onto. These residues, even in tiny amounts, can completely undermine the bond.

Moisture is another major factor. When water vapor becomes trapped beneath the concrete slab, it creates pressure that can push the epoxy right off the surface. This phenomenon, known as hydrostatic pressure, is a frequent cause of coating failures. Concrete that hasn’t fully cured – typically requiring at least 30 days – is especially prone to this problem.

"The main culprit to garage floor epoxy peeling up is poor preparation of the concrete surface." – All Garage Floors

Another issue is laitance, a thin, chalky layer of excess cement paste that forms on new concrete during the finishing process. If this layer isn’t removed – usually through grinding – the epoxy bonds to the laitance instead of the solid concrete underneath. When the laitance eventually detaches, the epoxy peels away with it.

Next, we’ll dive into other surface issues, like bubbles and pinholes, that can also affect the durability of epoxy floors.

Bubbles, Blistering, and Pinholes

Surface imperfections like bubbles and pinholes can diminish both the appearance and durability of epoxy floors. These flaws, while frustrating, are almost always avoidable with the epoxy and polyaspartic application techniques.

What Causes Bubbles and Pinholes

Bubbles and pinholes often result from outgassing – a process where air or gas escapes from the concrete, especially when exposed to direct sunlight. This creates small craters with a ridge around the edge and a tiny hole at the bottom where the gas escaped.

"Outgassing is a site condition that allows air or gas from the concrete substrate to escape in excess and cause blisters, craters, bubbles, or pinholes."

– Sherwin-Williams

Mixing epoxy too quickly – above 400 RPM – can also trap air, leading to bubbles that rise to the surface during application. Environmental factors like high humidity can cause condensation, resulting in a cloudy "epoxy blush." On the other hand, high temperatures can shorten the epoxy’s working time, causing it to form a skin before trapped air escapes. Applying the coating too thickly or working under direct sunlight can make these issues worse.

By understanding these causes, you can take steps to avoid these common pitfalls.

How to Prevent Bubbles and Pinholes

To minimize bubbles and pinholes, keep your mixer speed below 400 RPM and avoid lifting the mixer too close to the surface, which can draw air into the epoxy. After applying the epoxy, use a spiked roller or a propane heat gun held about 6 inches above the surface to release any trapped air bubbles.

Environmental conditions play a big role in epoxy application. For best results, work when temperatures are between 60°F and 90°F, and keep humidity below 85%. Avoid applying epoxy in direct sunlight or during the hottest part of the day. If the concrete is highly porous, consider sealing it with a moisture-resistant primer to reduce outgassing, or consider polyurea vs. epoxy for a more breathable alternative. Additionally, ensure the concrete is completely dry by waiting at least 24 to 48 hours after power washing or acid etching.

How to Fix Bubbles and Pinholes

For small imperfections, sanding the area, cleaning it with acetone, and applying a thin epoxy patch often does the trick. For larger blisters, lightly sand the area, remove loose coating with a wire brush, vacuum up debris, wipe with acetone, and scuff the surrounding intact coating using 100-grit sandpaper before reapplying.

If bubbling is widespread, it could signal a more serious issue, such as excessive moisture in the concrete or a major mixing error. In such cases, the entire coating may need to be stripped and reapplied. While bubbles don’t typically weaken the bond strength of the epoxy, addressing them quickly is essential to prevent moisture intrusion and maintain a polished, professional finish.

Cracks in Epoxy Floors

Cracks are one of the most annoying issues with epoxy garage floors. They don’t just ruin the look of the surface – they can also weaken its structure. Unlike bubbles or discoloration, cracks often point to more serious problems, like flaws in the concrete base or mistakes during the coating process. Let’s break down the causes, ways to prevent them, and how to fix cracked epoxy floors.

Why Epoxy Floors Crack

Epoxy is tough but brittle, meaning it doesn’t flex when the concrete underneath shifts. When the concrete moves – whether from settling, the weight of heavy vehicles, or poorly installed control joints – cracks can form. Temperature swings between 60°F and 100°F also create stress. Since epoxy and concrete expand at different rates, this mismatch can lead to cracking.

Mistakes during mixing can also cause problems. If you mix epoxy too fast (over 400 RPM) or don’t get the resin-to-hardener ratio right, it can generate too much heat, making the coating brittle and prone to breaking. On top of that, poor surface prep – like applying epoxy over laitance (a weak, dusty layer) or not properly etching the concrete – can result in a weak bond that eventually fails. In fact, inadequate surface preparation is responsible for up to 80% of epoxy floor failures.

How to Prevent Cracks

The first step in prevention starts with the concrete. Make sure the slab is on a solid, well-compacted base with proper reinforcement to limit movement. Instead of relying on acid etching, use diamond grinding to achieve a Concrete Surface Profile (CSP) of 2 or 3. Before applying epoxy, go over all control and expansion joints with a grinder and fill them with a flexible, epoxy-compatible sealant rather than covering them with rigid epoxy.

"Coating over expansion joints locks the slab movements into the epoxy, causing cracks along joint lines." – Southern Illinois Epoxy

Never apply epoxy over existing cracks. For cracks wider than 1/8 inch, use an epoxy patching compound or a vinyl-resin filler before adding the topcoat. Also, allow new concrete to cure for at least 30 days to prevent shrinkage-related cracks. When mixing epoxy, keep the speed under 400 RPM and maintain ambient temperatures between 60°F and 90°F during application to avoid overheating and ensure proper curing.

How to Repair Cracked Floors

For small cracks (less than 1/4 inch wide), a pourable concrete crack filler that self-levels works well. For larger or deeper cracks, use an epoxy patch reinforced with vinyl resin and fine sand. Start by cleaning the crack with a wire brush, vacuuming out debris, and wiping it down with acetone. Once the crack is filled and cured, lightly sand the surrounding area with 100-grit sandpaper before reapplying the epoxy primer and topcoat.

Keep in mind, epoxy won’t fill or bridge cracks on its own – it’s self-leveling but not a miracle fix. If a crack is wider than 1/8 inch or if one side of the crack is higher than the other, it could signal a structural issue that needs professional attention before any surface repairs are done. For floors with widespread cracking, the best solution may be to remove the entire coating, address the root of the problem, and start fresh.

Discoloration and Yellowing

Beyond structural problems like peeling and cracking, aesthetic changes such as discoloration can also take a toll on your garage floor’s appearance. While issues like cracks or bubbles can weaken the floor’s structure, yellowing mostly affects how it looks. Epoxy floors, for example, can shift from a clean, clear finish to an amber hue over time. Even though this doesn’t compromise the floor’s durability, it can make it look less appealing. Understanding what leads to discoloration can help you take steps to avoid it.

What Causes Yellowing

The main reason epoxy floors turn yellow is exposure to UV light. When epoxy is subjected to direct or strong sunlight, it undergoes a photochemical reaction known as polymer degradation, or "ambering." This reaction breaks down the coating, causing discoloration over time. In garages with lots of sunlight, standard epoxy can start fading or yellowing within just a few weeks. Even in areas with less sunlight, traditional epoxy coatings typically show signs of yellowing within 6 to 12 months.

"The primary cause for epoxy floor coatings turning a yellow color is exposure to U.V. light. Also known as ambering, when exposed to direct sunlight or strong indirect sunlight over a period of time, epoxy will experience a photochemical reaction known as polymer degradation." – All Garage Floors

But UV light isn’t the only factor. Oxidation can also lead to yellowing. This happens when the epoxy hardener reacts with oxygen, even in unopened containers, which is why epoxy products usually have a shelf life of about one year. Using low-quality materials, such as budget-friendly DIY kits, can worsen the problem. These kits often lack UV-stabilizing additives and rely on cheaper resins that discolor and lose their shine more quickly. Additionally, prolonged exposure to extreme heat speeds up the chemical reactions that degrade the polymer structure. Using harsh cleaners like bleach, ammonia, vinegar, or acetone can also lead to permanent staining or soft spots on the surface.

How to Prevent Yellowing

To keep your epoxy floor from yellowing, the best approach is to apply a UV-stable topcoat. Options like polyurethane, polyurea, or polyaspartic are specially designed to resist UV damage and won’t amber over time. It’s worth noting that "UV-resistant" epoxy only slows down yellowing, while "UV-stable" coatings are designed to maintain their color indefinitely.

Adding decorative flakes to the epoxy can also help. These flakes, made from UV-stable acrylic and vinyl resins, act as a shield against sunlight. If you prefer a cleaner look with fewer flakes, consider using a color-tinted polyurethane topcoat that matches the epoxy base, creating a fully UV-stable system. Choosing neutral tones like tan or beige can make yellowing less noticeable, as these colors naturally mask the ambering effect better than light grays or whites.

You can also limit UV exposure by keeping your garage door closed when it’s not in use and installing blinds or UV-blocking films on garage windows. For cleaning, stick with pH-neutral cleaners. Soap-based cleaners can leave behind a dull residue, and acidic chemicals may etch the floor’s surface. Unfortunately, once epoxy has yellowed, there’s no way to reverse it. The only solution is to sand down the surface and reapply a new UV-stable coating system.

Next, we’ll dive into the safety concerns associated with slippery epoxy floors.

Slippery Epoxy Floors

When it comes to garage safety, a slippery floor is a serious concern. While yellowing impacts the look of epoxy floors, their smooth, glossy finish can create a real hazard when wet. Whether it’s rainwater, melted snow, or oil drips from your car, wet epoxy floors can feel as treacherous as an ice rink. Let’s dive into why this happens and how you can address it.

Why Epoxy Floors Are Slippery

Epoxy flooring is seamless and non-porous, which means it naturally lacks texture. When liquids pool on the surface, they create a slick layer that significantly reduces friction. In fact, traditional epoxy flooring can increase the risk of slips and falls by as much as 40%. This issue is especially common in areas with frequent rain or snow, or in workshops where spills are more likely.

"Traction isn’t optional – it’s essential for garage safety. We’ve seen too many homeowners find their epoxy’s slippery nature the hard way, usually during the first rainy season after installation." – Galaxy Concrete Coatings

The smooth finish of standard epoxy often doesn’t meet OSHA’s slip-resistance standards, particularly when wet. Without some kind of texture, there’s little for your shoes to grip, making the surface unsafe.

How to Improve Traction

The good news? Slippery epoxy floors can be made safer with a few adjustments during installation. By adding anti-slip additives like aluminum oxide, silica sand, or polymer grit to the topcoat, you can create a textured surface that improves traction without compromising durability. Aluminum oxide, in particular, not only enhances grip but also boosts the floor’s toughness.

"Standard epoxy garage flooring can become slippery, especially when wet or exposed to oil. However, this issue is easily resolved by incorporating anti-slip additives into the final coat." – The Garage Floor Company

One effective method is broadcasting these additives into the wet coating, embedding them permanently into the surface. Decorative flakes can also be added to the base coat to create a layered texture that not only improves safety but also adds a stylish touch. To maintain traction over time, it’s important to use pH-neutral cleaners, which preserve the textured finish. The level of grit can even be tailored to your needs – higher grit for areas prone to snow and salt, or a lighter texture for typical residential garages.

Why Choose Penntek Evolution Coatings by Croc Coatings

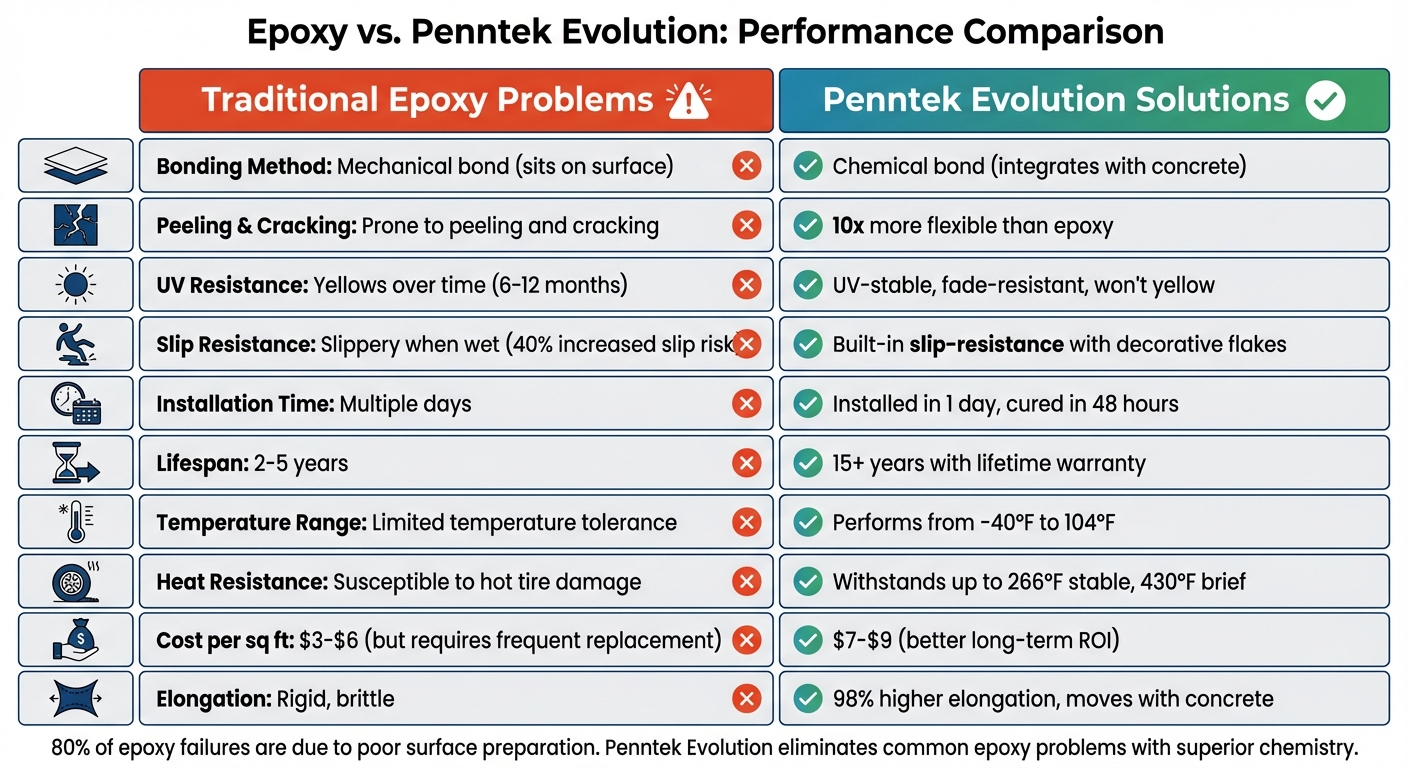

Epoxy vs Penntek Evolution Polyurea Coating Comparison

Say goodbye to peeling, cracking, yellowing, and slippery surfaces with a flooring solution that outperforms traditional epoxy in every way. Enter Penntek Evolution, a cutting-edge industrial coating system that’s four times stronger than epoxy. At the forefront of this transformation is Croc Coatings, a trusted provider of Penntek Evolution coatings in North Idaho and Eastern Washington, serving areas like Spokane and the Tri-Cities. Whether it’s your garage, patio, pool deck, basement, or industrial floor, their system offers unmatched durability and comes with a lifetime warranty for residential installations.

Penntek Evolution vs. Epoxy

The Penntek Evolution system is built on 100% pure polyurea, which sets it apart from epoxy in a big way. While epoxy merely forms a mechanical bond that sits on the surface of your concrete, polyurea creates a chemical bond, making it an integral part of the concrete itself. This difference isn’t just technical – it’s transformative.

Here’s how Penntek Evolution solves the problems commonly associated with epoxy:

| Problem with Epoxy | Penntek Evolution Solution |

|---|---|

| Peeling and cracking | Forms a chemical bond with concrete; 10x more flexible than epoxy |

| Yellowing or discoloration | UV-stable and fade-resistant; won’t yellow over time |

| Slipperiness when wet | Built-in slip-resistance with decorative flakes for added safety |

| Long installation time | Installed in one day; fully cured within 48 hours |

| Short lifespan (2–5 years) | Lasts over 15 years with a manufacturer’s warranty |

| Temperature sensitivity | Performs in extreme conditions from -40°F to 104°F |

| Heat damage from tires | Withstands stable heat up to 266°F and brief exposure to 430°F |

One standout feature is polyurea’s ability to handle freeze-thaw cycles without cracking, thanks to its 98% higher elongation compared to epoxy. It moves with the concrete, preventing the peeling and chipping that epoxy coatings often suffer from. As Croc Coatings explains:

"Epoxy keeps curing year after year so as it continues to harden, the movement of the concrete below eventually forces the coating to break free causing peeling, chipping and ultimately failure".

While epoxy might seem like the cheaper option at $3–$6 per square foot, its short lifespan (2–5 years) means frequent replacements. Penntek Evolution, priced between $7–$9 per square foot, offers a far better return on investment with its 15+ year lifespan. The upfront cost quickly pays off in reduced maintenance and long-term performance.

Additional Benefits of Croc Coatings

Penntek Evolution doesn’t just outperform epoxy – it makes life easier. Its nonporous surface repels oil, gas, antifreeze, and salt, simplifying cleanup. Plus, it’s antibacterial and antimicrobial, promoting a cleaner and healthier environment for your garage or workspace.

Croc Coatings also prioritizes safety and sustainability. They use low-VOC, eco-friendly materials, ensuring safer installations for your home and family. Their certified team completes the entire installation in just one day, and you can walk on your new floor within hours. For those looking to upgrade their space even further, they offer custom powder-coated garage cabinets made in the USA.

For pool decks, Croc Coatings provides a premium rubberized coating that enhances slip resistance, even when wet. Every installation is handled with precision, using industrial grinders to achieve the correct Concrete Surface Profile (CSP 3–4) and digital moisture meters to ensure a strong, lasting bond.

If you’re tired of the limitations of epoxy and want a flooring solution that stands the test of time, Penntek Evolution by Croc Coatings is the answer. With its durability, low maintenance, and safety features, it’s a game-changer for both residential and commercial spaces.

Conclusion

Epoxy garage floors can look stunning, but their durability depends heavily on precise installation. Studies indicate that up to 80% of epoxy floor failures stem from poor surface preparation, and DIY epoxy kits have a failure rate of up to 30% within just two years. Achieving a long-lasting, reliable floor requires proper surface preparation, moisture testing, and the use of professional-grade materials.

If you’re looking for a floor that won’t peel, crack, yellow, or become dangerously slippery, there’s a better option available. Enter Penntek Evolution by Croc Coatings. This polyurea-based system is a game changer – it’s 10 times more flexible than epoxy, forms a chemical bond with your concrete, resists UV damage without yellowing, and is installed in just one day. Even better, it cures within 24 hours and comes with a lifetime warranty for residential applications.

Whether you’re tackling an old floor that’s already causing problems or starting with a blank slate, professional installation with high-quality materials is the only way to avoid expensive fixes down the road. Croc Coatings uses industrial-grade tools like diamond grinders and moisture meters to ensure a flawless bond every time. Their certified installers serve North Idaho, Spokane, and the Tri-Cities, delivering results you can count on.

Don’t risk a floor that might fail in a few short years. Choose a solution designed to last, backed by experts who get it right the first time. With this advanced system, you’ll get the durability and performance you need without the headaches.

FAQs

How can I prepare my garage floor for an epoxy coating to ensure long-lasting results?

Proper preparation is the foundation of a long-lasting, flawless epoxy garage floor. Start by giving the area a thorough cleaning. Remove all items from the garage, sweep away debris, and ensure the surface is completely free of dust and cobwebs. Next, examine the concrete for any cracks, chips, or oil stains. Use a concrete filler to repair any damage, ensuring a smooth and even surface. After repairs, scrub the floor with a heavy-duty degreaser to eliminate grease, oil, and other residues. Rinse thoroughly and allow the floor to dry completely.

To ensure the floor is ready, test for moisture by taping a piece of clear plastic to the surface for 24 hours. If condensation appears underneath, address the moisture issue before moving forward. Once the area is dry and moisture-free, mechanically grind the surface to create the rough texture needed for the epoxy to bond properly. This step is critical for avoiding issues like peeling or bubbling later on. If the floor is porous or has lingering moisture concerns, applying a primer can help seal the surface and improve adhesion.

By carefully following these steps, you’ll set the stage for a clean and well-prepared surface, ensuring your epoxy coating adheres securely and stands the test of time. For a stress-free option, Croc Coatings offers professional installation completed in just one day, backed by a lifetime warranty and their advanced Penntek Evolution system.

How can I keep my epoxy garage floor from being slippery?

To keep your epoxy garage floor safe and less slippery, here are some practical steps you can take:

- Mix in a slip-resistant additive during installation. Adding materials like sand or polymer grit can create a textured surface, improving grip even when the floor is wet.

- Use a non-slip topcoat after the epoxy has cured. Coatings with anti-slip granules provide an extra layer of traction and durability.

- Maintain a clean and dry surface. Regular sweeping, mopping with a pH-neutral cleaner, and quickly addressing spills can prevent slick spots from forming.

If you’re looking for a tougher, more slip-resistant solution, consider the Penntek Evolution system from Croc Coatings. It’s four times stronger than standard epoxy and can be customized for extra safety. With the right preparation and upkeep, your garage floor can remain safe and functional for years to come.

What makes Penntek Evolution a better choice than traditional epoxy for garage floors?

Penntek Evolution is a polyurea-based coating system built to withstand the test of time. While traditional epoxy coatings often need replacing after just 2–5 years, this system is engineered to last 15 years or more, even in areas with heavy use.

What sets Penntek Evolution apart is its strength – it’s four times stronger than epoxy, making it highly resistant to peeling, cracking, and everyday wear. It’s a top choice for garage floors, but it’s also great for patios, pool decks, and basements. Plus, the system offers a quick one-day installation and comes with a lifetime warranty, giving you confidence that your floors will stay protected for years to come.

Related Blog Posts

- 7 Signs Your Garage Floor Needs a New Coating

- Polyurea vs. Epoxy: Eco-Friendly Garage Floor Options

- Top Anti-Slip Solutions for Garage Floors

- DIY Garage Floor Coating Mistakes to Avoid