Tools Needed for Polyurea Coating Prep

January 29, 2026

90% of coating failures happen because of poor surface preparation. To make your polyurea coating last 10–20 years, you need the right tools to clean, test, and prepare the surface properly. Here’s what you need to know:

- Inspection Tools: Moisture meters, calcium chloride tests, and relative humidity probes ensure the surface is dry and ready.

- Cleaning Tools: Pressure washers, HEPA vacuums, scrapers, and degreasers remove contaminants like grease, dirt, and old coatings.

- Mechanical Profiling Tools: Diamond grinders, shot blasters, and scarifiers help achieve the ideal Concrete Surface Profile (CSP) of 3–4 for strong adhesion.

- Repair Tools: Crack fillers and adhesion testers fix imperfections and confirm the surface is ready for coating.

- Safety Equipment: PPE, ventilation fans, and barriers protect workers and keep the workspace clean.

Proper tools ensure your polyurea coating bonds well and withstands heavy use. Skipping steps or using the wrong equipment can lead to peeling and delamination. Follow a concrete surface prep inspection checklist to get it right the first time.

Inspection and Testing Tools

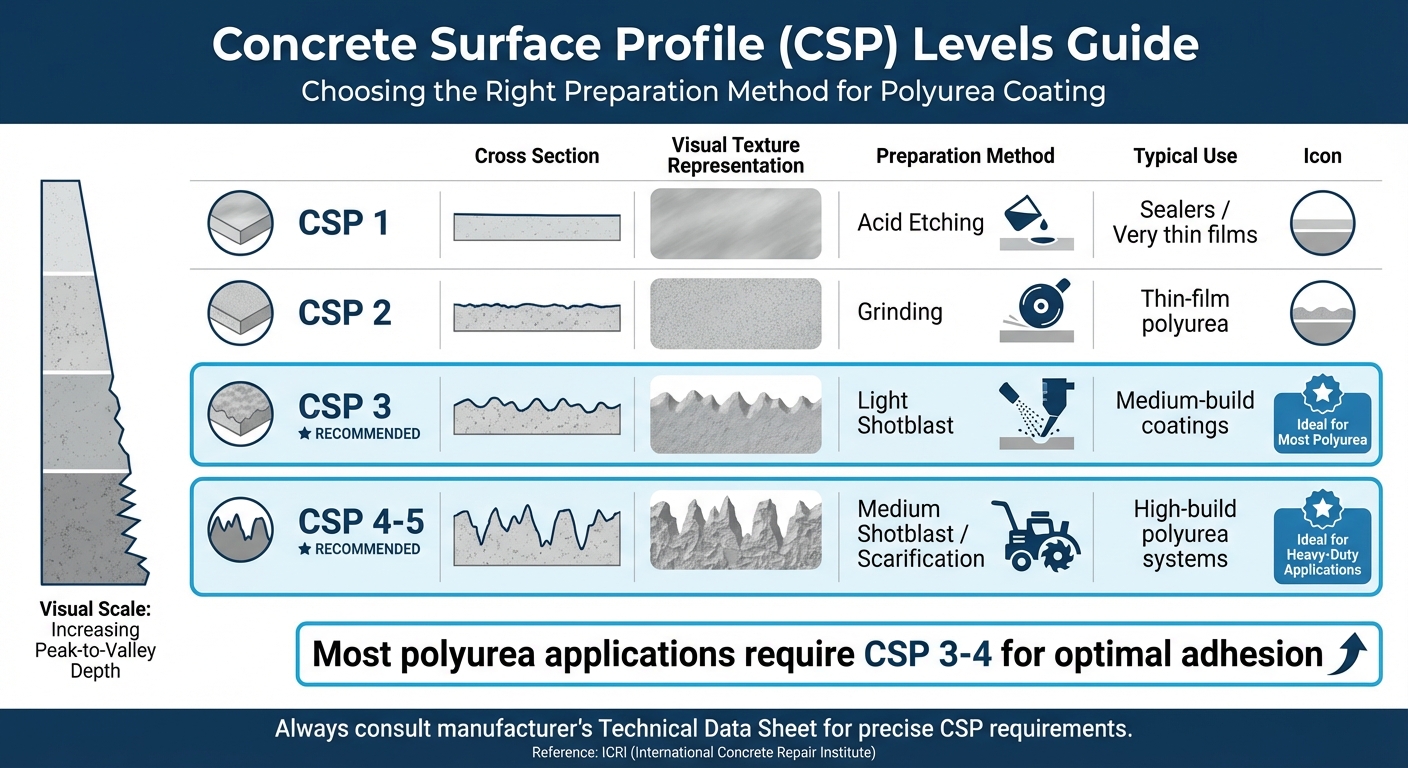

Concrete Surface Profile (CSP) Levels and Preparation Methods for Polyurea Coating

Before diving into mechanical profiling, it’s crucial to assess the substrate. Moisture within the substrate is one of the main culprits behind coating failures on concrete. This makes inspection tools an absolute necessity for a successful polyurea application.

Moisture Meters

Moisture testing determines if the concrete is ready for coating. For polyurea systems, the moisture vapor emission rate (MVER) must stay below 3 lbs per 1,000 sq. ft. over 24 hours. Exceeding this threshold increases the risk of delamination and coating failure.

- Calcium Chloride Tests: These tests measure the MVER from the concrete surface over 60 to 72 hours. Following ASTM F1869 standards, testing conditions should be maintained at 75°F (±10°F) and 50% (±10%) RH for 48 hours. This method quantifies the moisture escaping from the concrete, providing critical data for bonding success.

- Electronic Moisture Meters: These tools offer faster, non-destructive readings using various technologies:

- Radio Frequency Meters: Measure relative moisture up to 1 inch deep on a scale of 0–999, with values under 145 indicating safe dryness.

- Electrical Impedance Meters: Assess moisture content up to 6%.

- Conductivity Meters: Use contact pins to measure between two points, with readings under 85 units confirming moisture below 2%.

To ensure accuracy, perform dual testing: one test evaluates water penetration into the concrete (porosity), and the other measures vapor emission coming out of it. After profiling, spray water on the surface – if it beads or puddles instead of absorbing, further mechanical profiling is needed.

Once moisture levels are within acceptable limits, move on to verifying the surface texture with profile gauges.

Surface Profile Gauges

Surface profile gauges confirm that mechanical profiling created the right texture for polyurea adhesion. The International Concrete Repair Institute (ICRI) defines Concrete Surface Profile (CSP) standards from CSP 1 (nearly flat) to CSP 10 (very rough). Most polyurea applications require a CSP level of 3 to 4.

| CSP Level | Preparation Method | Typical Use |

|---|---|---|

| CSP 1 | Acid Etching | Sealers / Very thin films |

| CSP 2 | Grinding | Thin-film polyurea |

| CSP 3 | Light Shotblast | Medium-build coatings |

| CSP 4-5 | Medium Shotblast / Scarification | High-build polyurea systems |

These gauges rely on ICRI visual standards and benchmark profiles to measure the average distance between surface peaks and valleys. A surface that’s too smooth won’t allow the polyurea to grip properly, while an overly aggressive profile wastes material and risks showing texture through the finished coating. Always consult the manufacturer’s Technical Data Sheet for the precise CSP requirement before profiling. Proper surface preparation ensures a strong mechanical bond and prevents coating failures.

Once surface moisture and profile are verified, the next step is to assess in-slab humidity using RH probes.

Relative Humidity Probes

RH In Situ Probes provide an accurate snapshot of moisture conditions inside the concrete slab. This method involves drilling holes to 40% of the slab’s thickness, inserting sleeves or sensors, and sealing them for 72 hours to reach equilibrium. Testing follows ASTM F2170 standards.

These probes measure both ambient and in-slab humidity. Concrete typically cures at 80% to 85% relative humidity, and you’re looking for conditions that confirm the slab has dried sufficiently – usually after at least 28 days at 70°F.

Monitoring slab humidity is about more than avoiding delamination. For clear polyurea coatings, excess moisture can cause the finish to appear cloudy, ruining its look. By testing, you ensure the concrete has cured properly and hydration levels have stabilized, securing substrate stability and preventing coating issues.

sbb-itb-a0e5ae3

Cleaning and Surface Preparation Tools

Once you’ve tested for moisture and surface profile, the next essential step is decontamination. This involves using cleaning tools to eliminate oils, grease, dirt, and other contaminants that could prevent the coating from bonding effectively with the concrete. After cleaning, mechanical profiling tools are used to refine the surface texture and improve adhesion.

Pressure Washers

Pressure washers are great for removing contaminants like grease and oil stains from concrete surfaces, especially in areas like garage floors where vehicle fluids are common. However, pressure washing alone isn’t enough. Low-pressure water jetting, for instance, only achieves a Concrete Surface Profile (CSP) of 2 or less, which falls short of the level needed for proper polyurea adhesion.

"Low pressure water jetting and acid etching produce too low a CSP (2 and lower). They are simply not good enough for long-term bonding of a newly applied epoxy coating."

– Robert Hanson, President and Founder, GarageFloorCoating.com

While pressure washing is a good first step to clear surface contaminants, it should always be followed by mechanical profiling tools such as diamond grinders or shot blasters. Additionally, ensure the surface is fully dry before proceeding to the next step.

HEPA Vacuums

HEPA vacuums are essential for capturing fine dust and laitance – a weak, powdery layer of cement and sand fines left on the surface after profiling. If this layer isn’t removed, the polyurea coating may bond to it instead of the solid concrete, increasing the risk of delamination.

Industrial-grade vacuums designed for concrete dust typically range in size from 16 to 32 inches, making them suitable for handling the output of grinders. After vacuuming, test the surface porosity by spraying water on it. If the water beads or pools instead of soaking in, additional cleaning or profiling is needed.

"Lack of surface preparation causes 90% or more of overlay failures. The surface needs sufficient ‘bite’ for the overlay to bond, otherwise delaminating failure can result."

– Chris Sullivan, Technical Expert, Sullivan’s Corner

Scrapers and Degreasers

For stubborn residues like old coatings, flaking paint, rust, or scale that pressure washing might miss, manual scrapers are your go-to tools. Solvents and degreasers are also highly effective for breaking down embedded oils and grease, particularly in high-use areas such as vehicle parking lanes or industrial settings.

It’s crucial to ensure the surface is entirely free of oils, acids, salts, and other contaminants before applying a polyurea coating. After using degreasers, allow the surface to dry completely to maintain moisture levels below 8%. Pay extra attention to high-traffic spots like parking spaces, where tire marks and oil stains are common, and double-check corners and edges for leftover contaminants. Proper cleaning at this stage can significantly extend the life of your polyurea coating, often lasting 10–20 years or more.

Mechanical Profiling Tools

After removing contaminants, the next step is to create the proper surface texture that allows polyurea to adhere effectively. This involves using mechanical profiling tools to achieve a Concrete Surface Profile (CSP) of 3–4, which is considered ideal for polyurea bonding. Depending on the project size and surface conditions, different tools may be more suitable.

Diamond Grinders

Diamond grinders use rotating discs to strip away the weak upper layer of concrete (laitance) and leave behind a textured surface. These tools are perfect for smaller projects like residential garages, where a smooth but textured finish is needed.

"Grinders can produce CSPs of 3 and up to 4 in some cases, which, when prepping concrete for epoxy coating applications, is in the Goldilocks range."

– Robert Hanson, President and Founder, GarageFloorCoating.com

For larger tasks, propane-powered grinders are often preferred over electric ones. They eliminate the hassle of extension cords, produce less exhaust, and offer more power for deeper profiling. High-performance models, such as the Lavina 30-inch grinder, weigh around 750 pounds, providing the necessary pressure for thorough concrete profiling. Costs vary widely: single-head grinders range from $2,000 to $4,000, while four-head models can exceed $6,000. For temporary use, a 10-inch walk-behind grinder rents for $235–$450 per day.

However, grinders struggle with coatings thicker than 1/8 inch. In such cases, a scarifier is a better choice. To minimize dust, always pair your grinder with a HEPA-filtered vacuum, which can capture about 90% of the debris.

Shot Blasters

Shot blasters are highly efficient for prepping large industrial floors. They work by firing steel shot at high velocity to pulverize the concrete surface and remove contaminants. Shot blasters can achieve CSP levels between 2 and 7 without causing microcracks, making them ideal for removing thin, aged coatings over expansive areas.

These machines excel in speed and coverage compared to grinders, but they come at a steep cost – a walk-behind model with a 13-inch blast path can easily exceed $20,000. They are less effective on rubbery or elastomeric coatings, which are better addressed with grinding or scarifying methods. For commercial spaces like warehouses or parking garages, the investment may be worthwhile, but for smaller residential jobs, a grinder is likely a more practical option.

Scarifiers

Scarifiers, equipped with a rotating drum and toothed cutters, are the most aggressive profiling tools. They deliver a CSP range of 4–9, making them ideal for removing thick layers of mastics, old epoxy, or preparing surfaces for heavy-duty coatings. When dealing with coatings thicker than 1/8 inch, scarifiers are often the go-to option.

One downside is that scarifiers can cause microcracking, or "bruising", which may weaken the bond if not addressed. To counteract this, follow up with grinding or shot blasting to smooth out any surface damage. These tools are expensive – ride-on models with a 12-inch cutting swath can cost over $30,000 – so they are typically reserved for large-scale commercial or industrial jobs.

| Tool Type | CSP Range | Best Use Case | Microcracking Risk |

|---|---|---|---|

| Diamond Grinder | 3–4 | Residential garages, smoothing, light profiling | None |

| Shot Blaster | 2–7 | Large industrial floors, removing thin coatings | None |

| Scarifier | 4–9 | Removing thick mastics, heavy-duty milling | Moderate |

Before starting your project, test different tools on a small area to ensure the desired CSP is achieved. The best tool for the job depends on factors like coating thickness, project scale, and the surface profile recommended by your polyurea manufacturer.

At Croc Coatings, we prioritize thorough surface preparation to ensure our polyurea coatings last. For more tips and video tutorials on using these tools, check out the Croc Coatings YouTube channel. Once your surface is properly profiled, you can move on to repair and finishing tools to enhance adhesion further.

Repair and Finishing Tools

After mechanical profiling, the next step is all about fixing imperfections. Small voids, like bug and pinholes, need to be addressed to achieve a smooth and long-lasting finish. The tools in this category are designed to help repair these flaws and ensure the surface is ready for coating.

Crack Fillers and Applicators

Before applying polyurea, cracks in the concrete need to be routed and filled. Routing creates a clean channel, allowing the filler to bond effectively. Two-part polyureas are a popular choice for this task, often applied with automated mixing equipment. While epoxies and polyurethanes are also options, it’s essential to confirm compatibility with your primer system to avoid delamination.

"Our line of crack repair and joint filling equipment will save you a lot of time compared to using a manual dispensing gun, especially when you’re working with two-part polyureas."

– Graco

For small-scale jobs, a manual dispensing gun does the trick. But for larger projects, automated crack-filling machines are a game-changer. These machines mix and apply the material simultaneously, streamlining the process for large commercial floors. Once the filler cures, grind down any protrusions that exceed 1/16 inch.

After repairs, it’s crucial to confirm the surface is ready for coating by conducting adhesion tests.

Adhesion Testers

Adhesion testing ensures the surface is properly prepared for bonding. This step confirms that the weak laitance layer – a fragile film of cement and fines – has been removed, allowing polyurea to grip the solid concrete beneath. Use a water drop test and a Calcium Chloride test (ASTM F1249-13) to check porosity and moisture levels. If the water beads on the surface, further profiling is needed. Also, ensure the concrete has cured for at least 28 days at 70°F before testing or coating.

"There is rarely a successful polyurea application that does not include proper surface preparation and testing."

– Polyurea Systems

At Croc Coatings, testing is non-negotiable. Their proprietary Penntek Evolution system boasts strength that’s four times greater than epoxy, but that performance hinges on proper adhesion. For more tips on surface prep and testing, check out the Croc Coatings YouTube channel.

Safety and Protection Tools

Surface preparation can be hazardous – think dust, chemical vapors, and flying debris. To keep your crew safe and ensure the project goes smoothly, proper safety tools are a must. These not only protect workers but also play a key role in achieving a quality polyurea application that lasts.

Personal Protective Equipment (PPE)

When grinding or sanding, workers need full-body PPE, including respiratory protection. In confined or indoor spaces, use NIOSH-approved air-purifying respirators (APR) with organic vapor/P100 cartridges, powered air-purifying respirators (PAPR), or supplied-air respirators (SAR). OSHA 29 CFR 1910.134 guidelines require fit tests and seal checks for respirators to work properly. Facial hair that disrupts the seal? That’s a no-go.

For hand protection, opt for chemical-resistant gloves made from nitrile, neoprene, butyl, or PVC to shield against harsh chemicals and cleaning solvents. Protect eyes with safety goggles or a face shield, and always have an eyewash station or safety shower nearby in case of exposure to corrosive materials. Disposable, chemically resistant long-sleeve coveralls with hoods are essential, along with MDI-resistant boots or booties for full-body protection.

| PPE Category | Recommended Equipment for Prep & Cleaning |

|---|---|

| Respiratory | NIOSH-approved APR with organic vapor/P100 cartridges or SAR |

| Gloves | Nitrile, neoprene, butyl, or PVC (MDI-resistant) |

| Eye Protection | Chemical safety goggles or full-face respirator |

| Clothing | Chemically resistant coveralls (with hood) or MDI-resistant apron |

| Footwear | Safety boots or MDI-resistant fitted booties |

| Head | Hard hat (if falling object hazards exist) |

Once PPE is sorted, the next step is managing airborne contaminants with ventilation.

Ventilation Fans

Ventilation fans are key for maintaining airflow in enclosed spaces where dust and chemical vapors can build up. For effective cross-ventilation, position fans so that supply air comes from one side and exhaust air exits from the opposite side. To maintain negative pressure, ensure the exhaust fan’s capacity is about 10% higher than the supply fan’s. A smoke tube can help confirm proper airflow. Also, seal off existing HVAC openings to stop contaminants from spreading to other parts of the building. Keep the ventilation running even after the work is done – until the material has fully cured and off-gassing has ceased.

Barriers and Tarps

Tape, sheeting, and physical barriers are your best friends for protecting non-target surfaces from dust and debris. Before using mechanical profiling equipment, cover surrounding structures, equipment, and landscaping. This prevents concrete dust from settling on sensitive areas and cuts down on cleanup time. Pairing barriers with a triple HEPA-filtered vacuum system – which captures about 90% of airborne dust during grinding – creates a cleaner workspace. Once the barriers and tarps are removed, vacuum thoroughly to eliminate any remaining debris, ensuring the surface is spotless before applying the coating.

Conclusion

The steps of inspection, cleaning, and profiling are essential when preparing surfaces for polyurea coatings, but the right tools are what truly set the stage for success. Without the proper equipment, even the highest-quality coatings can fail to perform.

"Surface preparation is the key element for long term success. The concrete surface must allow the coating to absorb into the surface of the concrete to create a strong mechanical bond." – Garage Flooring LLC

Using diamond grinders to achieve the ideal CSP (Concrete Surface Profile) of 3–4 ensures a strong mechanical bond while minimizing surface imperfections. Additionally, testing tools help confirm that the substrate is dry and ready for coating, preventing common issues like delamination or cloudiness. For example, exceeding moisture levels of 3 lbs per 1,000 sq. ft. within 24 hours can weaken the bond strength. These steps collectively have a direct impact on the coating’s durability and performance.

When preparation is done correctly, the results speak for themselves. A properly prepped and coated floor can last anywhere from 10 to 20 years – even in heavy-use environments. This kind of longevity reduces maintenance needs, minimizes callbacks, and boosts customer satisfaction. Whether you’re coating a residential garage or a large commercial space, the tools and techniques used during preparation are critical to the coating’s long-term success.

Croc Coatings’ Penntek Evolution industrial coating system is four times stronger than epoxy. However, that strength only delivers results when paired with meticulous surface preparation. By using professional-grade tools and following strict preparation protocols, Croc Coatings ensures that their polyurea coatings not only outperform industry standards but also provide lasting durability – guaranteed by their lifetime warranty.

FAQs

Why is achieving the correct Concrete Surface Profile (CSP) crucial for polyurea coatings?

Achieving the right Concrete Surface Profile (CSP) is crucial for ensuring that a polyurea coating bonds effectively to the surface. When the CSP is properly prepared, it creates a strong mechanical connection between the concrete and the coating, reducing the risk of common problems like peeling, blistering, or delamination over time.

Additionally, the correct CSP contributes to the coating’s ability to perform under tough conditions, including heavy traffic and exposure to various elements. In short, surface preparation is the key to a durable, high-quality finish that stands the test of time.

How does moisture affect the application of polyurea coatings?

Moisture is a key factor that can make or break the success of polyurea coatings. When concrete has high moisture levels, it can lead to problems like poor adhesion, bubbling, peeling, or even delamination. These issues can significantly affect the coating’s durability and performance.

To avoid these outcomes, it’s essential to check the moisture levels in the concrete before applying the coating. Tools like moisture meters or even a simple water drop test can help you determine whether the surface is ready. For the best results, aim for a moisture content of less than 8%. This ensures proper adhesion and helps the coating last longer.

What safety precautions should be followed when preparing a surface for polyurea coating?

To stay safe while preparing surfaces for polyurea coatings, always wear the right personal protective equipment (PPE). This includes gloves, safety goggles, and a respirator – especially when handling chemicals, cleaners, or performing abrasive tasks like grinding or shot blasting. Make sure there’s adequate ventilation to prevent inhaling harmful dust or fumes. Using dust extraction systems or working in open, airy spaces can help.

If you’re using power tools such as grinders or shot blasters, stick to the manufacturer’s safety guidelines. Check the equipment for any damage and maintain a safe distance from moving parts. Training on how to properly use tools and handle chemicals is essential for safety. Additionally, inspect the surface for potential hazards and conduct moisture tests to ensure both safety and the best coating results. These steps not only create a safer work environment but also set the stage for a successful application.

Related Blog Posts

- How to Prepare Concrete for Polyurea Coatings

- Ultimate Guide to Surface Preparation for Concrete Coatings

- How to Clean Concrete for Coating Prep

- Why Surface Prep Matters for Concrete Coatings