Polyurea Coatings Support FAQs

December 20, 2025

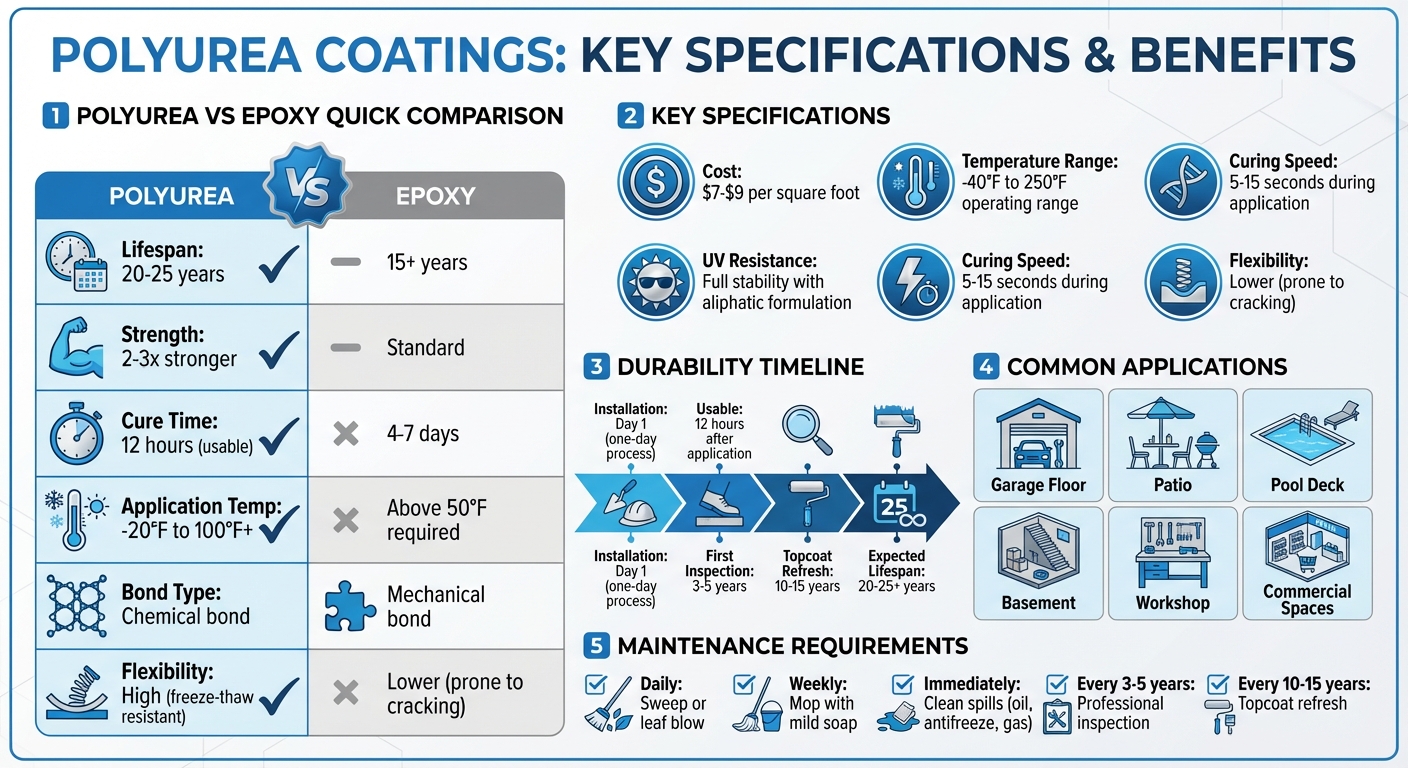

Polyurea coatings are a durable, long-lasting solution for protecting concrete surfaces in homes and businesses. Compared to epoxy, polyurea forms a chemical bond with concrete, lasting over 15 years, and offers greater flexibility to withstand freeze-thaw cycles without cracking. Proper installation is critical, requiring precise surface preparation, testing concrete moisture, and skilled application. Here’s what you need to know:

- Durability: Lasts 20–25 years with proper care.

- Cost: Typically $7–$9 per square foot.

- Advantages: Handles extreme temperatures (-40°F to 250°F), resists UV damage (with aliphatic formulations), and cures quickly (usable within 12 hours).

- Maintenance: Regular sweeping, mild cleaning, and occasional topcoat refreshes extend its lifespan.

- Warranty: Covers manufacturing defects like peeling or flaking but excludes issues caused by improper installation or moisture problems.

Polyurea coatings are ideal for garage floors, patios, pool decks, and commercial spaces. For support or repairs, contact your installer promptly to address any issues like chips or bubbling. Proper maintenance ensures your investment performs as expected for decades.

Polyurea vs Epoxy Coatings: Performance Comparison Chart

What You Need to Know About Polyurea Coatings

What Are Polyurea Coatings?

Polyurea was first developed in the early 1980s as a solution to the moisture sensitivity issues found in polyurethane products. Andy Phelan, Director of Business Development and Training at Rhino Linings Corporation, explains:

"Polyurea was invented in the early 1980s when a less moisture-sensitive form of polyurethane was desired… It has significantly less sensitivity to moisture than other urethane-based coatings."

One of the standout features of polyurea is its rapid curing time – it can set in seconds or minutes, even in extreme conditions ranging from -20°F to over 100°F. This makes it a more versatile option compared to traditional epoxy, which typically requires temperatures above 50°F to perform effectively. As Marvel Industrial Coatings puts it:

"Polyurea coatings thrive where others struggle. They can be applied in freezing temperatures as low as -20°F… making them ideal for cold climates and fast-track projects."

Polyurea doesn’t just handle temperature extremes; it also boasts remarkable strength and flexibility. It remains resilient in temperatures spanning -40°F to 250°F and is estimated to be 2 to 3 times stronger than standard epoxy floors. Most formulations are 100% solids, meaning they contain no solvents or VOCs, which helps eliminate shrinkage during curing. These coatings can be applied in single passes ranging from 20 to 500 mils.

When it comes to UV exposure, the type of polyurea matters. Aromatic polyurea is suitable for indoor use but tends to yellow under UV light. On the other hand, comparing polyurea vs. epoxy UV stability shows that aliphatic polyurea combined with polyaspartic topcoats ensures full UV stability, making it ideal for outdoor projects. Professional systems, such as those used by Croc Coatings, often pair a pure polyurea basecoat with a UV-stable clear coat to deliver top-tier performance in any environment.

Thanks to these robust characteristics, polyurea coatings are a go-to choice for a wide range of uses.

Where Polyurea Coatings Are Used

With its advanced properties, polyurea has become a practical solution for numerous applications. It’s commonly used on garage floors, workshops, patios, pool decks, basements, and commercial spaces. Its chemical bond and flexibility make it especially effective in harsh conditions, such as freeze-thaw cycles, exposure to road salt, chemical spills, and heavy foot or vehicle traffic.

One of polyurea’s key advantages is its flowable composition, which allows it to penetrate deeper into concrete pores compared to thicker epoxy coatings. This creates a stronger bond with the substrate, making it an excellent choice for concrete slabs, vertical foundation edges, and stairs that require long-term durability.

For homeowners and businesses in regions with extreme weather, polyurea offers impressive resistance to oil, gas, antifreeze, and salt, providing a reliable way to protect concrete surfaces. Another major benefit is its quick turnaround time – floors coated with polyurea are often ready for use within 12 hours, while epoxy-coated floors typically take 4 to 7 days to fully cure.

Installation and Maintenance

The Installation Process

Getting a polyurea coating installed correctly is key to making sure it lasts and performs well. It all starts with surface preparation – the concrete needs to be clean, dry, and free from contaminants. This often involves grinding or shot blasting to create a textured surface that helps the coating bond effectively.

Testing for moisture is also a critical step. If the concrete has too much moisture, the coating might not adhere properly, which could lead to bubbling or peeling. As Southwest Exteriors points out:

"If there is too much moisture in the concrete, the coating will not bond properly to the concrete"

When moisture is detected, installing a barrier is necessary to ensure proper adhesion.

Polyurea is known for its rapid curing time – it sets in just 5–15 seconds during application. The coating is applied in even layers using a roller or sprayer, and multiple coats can be added for extra durability. However, this quick cure time means the application process requires precision and speed to avoid issues like air bubbles. Floor Shield Coatings emphasizes:

"The quick cure time of polyurea can be a blessing and a curse… it demands precision and speed during application"

Companies like Croc Coatings streamline this process into a one-day installation. For instance, they completed a garage floor project in Coeur d’Alene, Idaho, in December 2025. Their thorough preparation and professional application made the floor ready to use within hours. As they describe it:

"We handle everything, so you can start enjoying your new floors right away."

This efficient and professional approach ensures a durable, high-performing surface that lasts. Once installed, maintaining your polyurea coating is simple and helps keep it in top condition.

Maintaining Your Polyurea Coating

With proper care, polyurea coatings can last 20–25 years. The good news? Keeping them in great shape is straightforward and doesn’t require any complicated products or techniques.

Daily sweeping or using a leaf blower helps remove dirt, sand, and grit that could scratch the surface. A weekly mop with mild dish soap or warm water works well to maintain its clean and shiny appearance. If needed, a small amount of ammonia can be added, but avoid harsh chemicals like bleach, vinegar, or acidic cleaners, as they can damage the finish.

Spills, especially from automotive fluids like oil, antifreeze, or gasoline, should be cleaned up immediately to prevent stains or surface damage.

For long-term care, scheduling a professional inspection every 3–5 years and refreshing the topcoat every 10–15 years is a smart move. This not only restores UV protection but can also extend the coating’s life well beyond 20 years. As concrete-coating expert Crayton Caudill explains:

"Polyurea polyaspartic coatings have emerged as a long-lasting, flexible, and increasingly popular alternative… offering an expected lifespan of up to 20 or even 25 years"

Warranty and Customer Support

What the Warranty Covers

Croc Coatings provides a lifetime warranty that protects against manufacturing defects and wear. This coverage aligns with the impressive durability of polyurea, which, with proper maintenance, can last over 20 years. Polyurea’s resilience is well-documented, retaining more than 80% of its strength even after prolonged UV exposure.

The warranty specifically addresses problems like peeling, flaking, or bond failures caused by manufacturing defects. However, it does not cover issues linked to installation errors, such as air bubbles, improper mixing, or applying the coating to concrete with high moisture levels. For outdoor areas like patios or driveways, it’s essential to use a coating formulated for UV resistance to prevent fading – standard formulations may not offer the same level of protection.

Polyurea technology has been a trusted solution since 1988, with decades of proven performance.

When to Reach Out for Support

A strong warranty is only part of the equation – timely support is crucial to safeguarding your investment.

If you notice chips, scratches, or divots in your coating, contact Croc Coatings right away. Addressing these issues quickly can prevent moisture from seeping into the concrete, which could lead to further damage. The team can use specialized fillers to repair these areas and restore the protective seal.

You should also reach out if you notice unexpected peeling or bubbling, particularly if moisture seems to be coming through the concrete slab. While polyurea is exceptionally durable, excessive moisture vapor can weaken the bond. Similarly, for outdoor coatings, if you observe fading or unusual surface changes, support can help determine if the problem qualifies for warranty coverage.

Be mindful of cleaning products, as harsh chemicals like bleach or vinegar can harm the coating’s finish. If such cleaners have been used and you see signs of damage, contact support to assess the situation. For warranty claims or repair assistance, call 480.382.9690 or use the online contact form available on the Croc Coatings website.

sbb-itb-a0e5ae3

Polyurea Application For Garage Floors Tutorial

Conclusion

Polyurea coatings can provide over 25 years of durability when installed by professionals, maintained correctly, and supported with reliable service. As we’ve discussed, every step – installation, maintenance, and care – plays a vital role in ensuring this longevity.

The foundation of a successful polyurea coating starts with proper surface preparation. Concrete surfaces need to be mechanically ground to achieve the right texture for the coating to bond effectively. Cutting corners with methods like acid etching won’t yield the same results. Given how quickly polyurea cures, mistakes during the installation process can be challenging to fix. Contaminants like dust, oil, or grease can cause the coating to detach in large sheets rather than small flakes.

Once installed, routine maintenance is key to keeping your coating in great shape. Regular sweeping and gentle cleaning are usually enough to maintain its performance. Addressing issues as they arise can further extend the life of your floor.

If you spot chips, scratches, or any unexpected changes in the coating, repairing them promptly helps protect your investment. For warranty claims or repair assistance, you can reach Croc Coatings at 480.382.9690 or use the contact form available on their website.

FAQs

What makes polyurea more durable and flexible compared to epoxy?

Polyurea is known for its outstanding strength and versatility, offering a lifespan of 20–25 years – far surpassing the 5–10 years typically seen with epoxy coatings. This durability stems from polyurea being nearly four times stronger than epoxy, making it an excellent option for areas that face heavy traffic or demanding use.

What really sets polyurea apart, though, is its flexibility. Thanks to its elastomeric properties, it boasts about 98% greater elongation compared to epoxy. This means it can handle temperature shifts and impacts without cracking, while epoxy, being more rigid, is more susceptible to wear and tear over time. With its combination of strength and adaptability, polyurea is a solid choice for both residential and commercial applications.

What steps are essential for a proper polyurea coating installation?

To get a durable, long-lasting polyurea coating, here’s what you need to do:

- Inspect the concrete: Look for cracks, contaminants, or moisture problems. Tackling these issues upfront helps prevent peeling or adhesion failures down the line.

- Thoroughly clean the surface: Remove all grease, oil, and debris. A spotless surface is key to ensuring the coating sticks properly.

- Repair and prep the surface: Fill in any cracks and create a textured surface using tools like diamond grinders or shot blasters. This step improves the coating’s ability to adhere.

- Apply primer and base coat: Start with a primer to seal the surface, then evenly spread the polyurea base coat, following the recommended thickness.

- Ensure proper curing conditions: Keep the temperature between 60°F and 85°F and avoid any traffic or exposure to moisture during curing. This step is crucial for achieving the best results.

Stick to these steps, and you’ll end up with a professional-grade finish that meets Croc Coatings’ high standards and is built to last.

What’s the best way to care for my polyurea-coated surface to ensure it lasts?

Maintaining your polyurea-coated surface doesn’t take much effort, but it goes a long way in keeping it durable and looking its best over time. Here are some tips to help you take care of it:

- Sweep or dust frequently to clear away dirt and debris that might scratch the surface.

- Use a pH-neutral cleaner weekly with a microfiber mop for cleaning. Steer clear of harsh chemicals or abrasive tools that could harm the coating.

- Clean up spills right away to avoid stains or potential damage from substances like oil or gasoline.

- Add extra protection in high-traffic spots by using rugs, mats, or furniture pads to minimize wear and tear.

- Fix chips or scratches quickly with a compatible filler or reach out to Croc Coatings for professional repairs.

By following these steps, you’ll extend the life of your coating, keep it resistant to stains and chemicals, and ensure the lifetime warranty from Croc Coatings stays intact.

Related Blog Posts

- Top 5 Benefits of UV-Stable Polyurea Coatings

- How Polyurea Coatings Resist Wear Over Time

- Polyurea vs. Epoxy: Best for Humid Areas

- Impact Resistance in Harsh Climates: Polyurea Benefits