How Moisture Affects Concrete in the Pacific Northwest

December 23, 2025

Moisture is the #1 enemy of concrete in the Pacific Northwest. Heavy rainfall, freeze-thaw cycles, and high humidity create the perfect storm for cracking, chemical damage, and structural weakening. Here’s what you need to know:

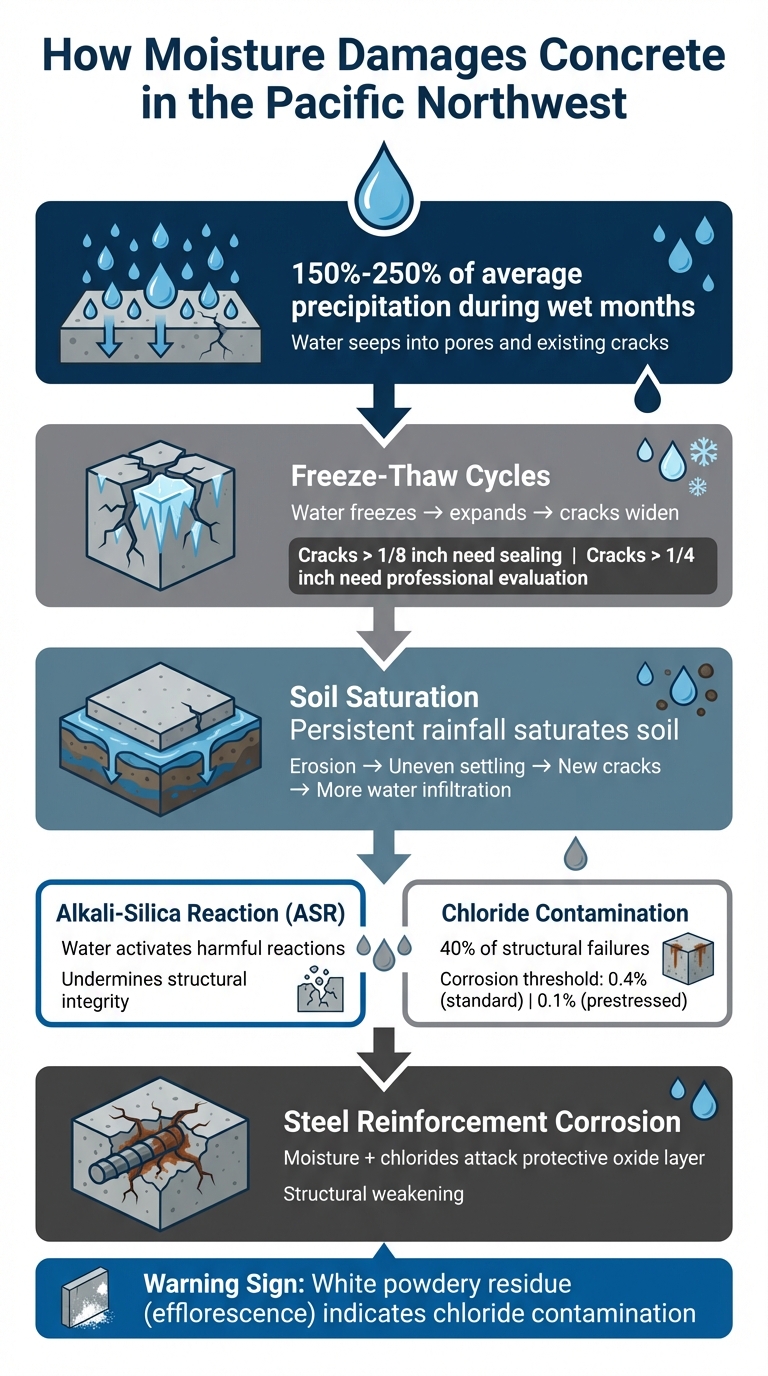

- Rainfall Impact: The region sees 150%-250% of average precipitation during wet months, saturating soil and concrete.

- Freeze-Thaw Damage: Water in cracks freezes, expands, and worsens structural issues.

- Chemical Reactions: Moisture triggers alkali-silica reaction (ASR) and chloride contamination, leading to corrosion and deterioration.

- Solutions: Use vapor barriers (10-20 mil thick) beneath slabs and durable surface coatings like polyurea to block moisture from all sides.

Takeaway: If you’re in areas like Spokane or the Tri-Cities, protecting your concrete with proper moisture management – both below and above the surface – can prevent costly repairs.

How to Handle High Moisture Levels in Concrete Slabs

How Moisture Damages Concrete in the Pacific Northwest

How Moisture Damages Concrete: From Infiltration to Structural Failure

Cracking and Weakening from Moisture

Concrete may seem tough, but water can exploit its vulnerabilities, especially in the Pacific Northwest. Moisture seeps into the concrete’s pores and existing cracks, setting the stage for damage. When temperatures drop below freezing, the trapped water turns to ice and expands, forcing cracks to widen with each freeze-thaw cycle. According to research from MIT’s Concrete Sustainability Hub, this phenomenon occurs due to "disjoining ionic pressure" at the interface between ice and the calcium-silicate-hydrate matrix within the concrete’s tiny capillary pores.

Here’s a quick tip: if you can fit two U.S. quarters side-by-side into a crack and the gap is more than 1/8 inch, it’s time to seal it. If the gap exceeds 1/4 inch, it’s wise to call in a professional for an evaluation.

But it’s not just cracks that water exploits. Persistent rainfall can saturate the soil beneath concrete slabs, weakening their support. This can lead to soil erosion, which creates new drainage paths and causes the slab to shift or settle unevenly. These movements often result in fresh cracks, inviting even more water to infiltrate. Additionally, when moisture reaches steel reinforcements within the concrete, it triggers corrosion, which further weakens the structure.

Beyond these physical effects, moisture also initiates chemical processes that gradually deteriorate concrete.

Chemical Damage from Water Exposure

Water doesn’t just damage concrete physically – it also sparks chemical reactions that can compromise its strength over time. One major culprit is alkali-silica reaction (ASR), a process where water activates harmful reactions within the concrete, undermining its structural integrity.

Chloride contamination is another significant issue, accounting for roughly 40% of structural failures in reinforced concrete. In the Pacific Northwest, chloride ions from de-icing salts or marine environments can penetrate concrete through its pores. Once inside, these ions attack the protective oxide layer surrounding steel reinforcements. For standard concrete, corrosion accelerates when chloride levels exceed 0.4% by the weight of cement; for prestressed concrete, the threshold is even lower at 0.1%.

Water can also carry dissolved minerals through the concrete via capillary action. When the water evaporates, it leaves behind a white, powdery residue called efflorescence. While unsightly, this residue can act as an early warning sign of chloride contamination. On top of that, moisture can transport alkalis in a high-pH solution, which may

How Moisture Barriers Protect Concrete

In the Pacific Northwest, where heavy rainfall and persistent humidity are the norm, moisture barriers play a key role in preserving concrete structures. These barriers work by either blocking moisture from reaching the concrete entirely or sealing its surface to protect it. Both methods help slow down moisture-related damage, significantly extending the life of the concrete.

Vapor Barriers for Long-Term Protection

Vapor barriers are designed to stop moisture from the ground before it even reaches the concrete slab. These barriers are typically made from 10–20 mil plastic membranes, which are placed directly beneath the slab to prevent water from moving upward through the soil.

"A commonly used thickness for a plastic concrete vapor barrier is 10 mil. This is generally accepted as the minimum thickness for concrete installations."

– Farm Plastic Supply

For outdoor projects in the Pacific Northwest, contractors often use thicker 15 mil barriers to ensure durability. These barriers must comply with ASTM 1745 standards, as this guarantees they can withstand the rigors of construction without tearing. In areas where the soil retains water, an extra measure is taken: a 6-to-8-inch layer of coarse gravel or crushed stone is added beneath the vapor barrier. This layer acts as a capillary break, further reducing the movement of moisture from the soil.

Even with vapor barriers in place, concrete slabs require significant drying time – anywhere from six weeks to over a year. Before adding floor coverings or coatings, the slab’s moisture levels must be tested. Common testing methods include the Relative Humidity Probe (ASTM F 2170) and the Anhydrous Calcium Chloride Test (ASTM F 1869). Many manufacturers specify that moisture vapor emission rates should not exceed 3 to 5 pounds per 1,000 square feet per 24 hours.

While these beneath-the-slab measures are effective at blocking ground moisture, protecting the surface from above is equally important.

Surface Coatings for Moisture Protection

Surface coatings provide a top layer of protection, shielding concrete from moisture, salt, and chemicals that come from above. Polyurea coatings are particularly effective because they create a seamless, non-porous seal that bonds chemically with the concrete.

Unlike epoxy, which forms a weaker mechanical bond and is prone to issues like blistering and delamination when moisture gets trapped, polyurea’s chemical bond is far more durable. In fact, polyurea coatings can last 20 to 40 years, compared to epoxy’s typical lifespan of just 3 to 5 years.

Another major advantage of polyurea is its flexibility. These coatings are designed to expand and contract along with the concrete as it responds to seasonal temperature changes and ground movement. This flexibility is critical in the Pacific Northwest, where freeze-thaw cycles and saturated soils can cause significant stress on concrete surfaces. Unlike rigid coatings that may crack or chip under these conditions, polyurea coatings maintain their integrity.

sbb-itb-a0e5ae3

Croc Coatings: Moisture-Resistant Concrete Protection

Croc Coatings’ Penntek Evolution system offers a tough, moisture-resistant solution designed specifically for the challenges of the Pacific Northwest. Whether you’re in North Idaho, Spokane, or the Tri-Cities, this system is four times stronger than traditional epoxy and built to withstand the chemical wear and tear that often causes standard coatings to break down in damp climates.

Unlike traditional epoxy, which can succumb to hydrolysis and lose its structure when exposed to moisture, the Penntek Evolution system maintains its strength even under intense vapor pressure that forces water through concrete slabs. This is especially vital in areas where saturated soil generates tens of thousands of pounds of hydrostatic pressure.

The system also addresses two key concerns in the region: UV stability and antibacterial properties. UV stability prevents the coating from becoming brittle or developing micro-cracks due to sun exposure, while the antibacterial design helps stop mold and mildew from forming in damp conditions. Together, these features ensure surfaces remain clean and durable, even in environments prone to organic growth. On top of that, the system is installed quickly, with a fast-track process that cuts down on exposure to unpredictable weather.

The entire installation can be completed in just one day, significantly reducing the risk of freshly applied coatings being affected by rain or other environmental factors. Its non-porous finish prevents water absorption, solving many moisture-related problems.

Where to Use Croc Coatings

The Penntek Evolution system is versatile enough for both residential and commercial use across North Idaho and Eastern Washington. Garage floors benefit from exceptional resistance to impacts, abrasions, and chemicals, making them ideal for harsh winters and wet road conditions. Basements are also well-protected, with the coating shielding against ground moisture, hydrostatic pressure, and mold growth.

For outdoor spaces like patios and pool decks, the UV-stable formula ensures long-lasting protection without yellowing or fading, even under direct sunlight. Croc Coatings also offers a rubberized coating option for pool decks, combining slip resistance with a stylish finish – perfect for wet, high-traffic areas.

Lifetime Warranty and Easy Maintenance

Croc Coatings backs the Penntek Evolution system with a lifetime warranty for residential use and a 5-year warranty for commercial applications. Thanks to its non-porous finish, maintenance is minimal – just occasional sweeping and mopping are enough to keep it performing at its best. This makes it a practical, low-maintenance solution for areas prone to moisture and wear.

Conclusion: Protecting Concrete from Pacific Northwest Moisture

The Pacific Northwest’s wet climate poses a serious threat to concrete surfaces. Heavy rainfall saturates the ground, and high water tables create hydrostatic pressure that can weaken, crack, and chemically damage unprotected concrete. Prolonged exposure to moisture often results in bond failures, delamination, and even mold growth. To combat these challenges, a two-pronged approach is essential – one that prevents moisture from rising and protects the surface itself.

This protection involves using both vapor barriers and specialized surface coatings. Vapor barriers, typically 10 to 20 mils thick, stop groundwater from seeping upward through concrete. Meanwhile, moisture-resistant surface coatings act as a shield, preventing vapor from penetrating the concrete’s surface. This dual strategy is especially important in regions like North Idaho, Spokane, and the Tri-Cities, where damp soil and unpredictable weather conditions put additional strain on concrete structures.

"Failure to take into account the moisture mitigation of your concrete floor can be expensive and cause headaches down the road." – Duraamen Engineered Products

Croc Coatings’ Penntek Evolution system is a perfect example of this dual-protection approach. Designed to block water vapor, it also offers UV stability and antibacterial properties, ensuring long-term durability. With the added benefits of a one-day installation process and a lifetime warranty for residential applications, this system provides a practical and reliable solution for homeowners and businesses looking to safeguard their concrete against the Pacific Northwest’s challenging climate.

If you’re looking to protect your garage floor, basement, patio, or pool deck, now is the time to act. Proper moisture management today can save you from costly repairs and headaches in the future.

FAQs

How do freeze-thaw cycles damage concrete in the Pacific Northwest’s wet climate?

Freeze-thaw cycles take a heavy toll on concrete in the Pacific Northwest, thanks to the region’s consistently wet climate. Here’s what happens: water seeps into the tiny pores of the concrete. When temperatures drop and that water freezes, it expands by about 9%, putting immense internal pressure on the material. Unfortunately, concrete isn’t built to handle this kind of stress, leading to surface spalling and internal cracks. And with each freeze-thaw cycle, the damage only gets worse.

Concrete without proper air-entrainment is especially at risk. Without this feature, the material can’t adequately handle the stress caused by expanding ice. Over time, these cycles can weaken both the strength and appearance of concrete surfaces. That’s why protective steps like applying moisture barriers or using durable coatings are so important – they help shield the concrete and extend its lifespan.

What materials work best for vapor barriers to protect concrete in wet climates?

To safeguard concrete in damp areas like the Pacific Northwest, thick and durable vapor barriers are a must-have. The top choices include low-density polyethylene film (with a thickness of at least 10 mil) and advanced plastic sheeting, such as EVOH-based membranes. These materials are highly effective at blocking moisture, provided they comply with ASTM E 1745 standards and have a permeance rating of less than 0.3 perm.

Investing in high-quality vapor barriers is crucial for preventing moisture from penetrating concrete surfaces. This helps minimize the risk of issues like cracking, spalling, and other water-related damage. However, the key to achieving long-lasting protection lies in proper installation.

What makes the Penntek Evolution coating better than traditional epoxy for concrete surfaces?

The Penntek Evolution system stands out as a superior alternative to traditional epoxy coatings. Designed with a polyurea base, it offers four times the tensile strength of epoxy, making it much better at resisting cracks and impact damage. Additionally, its nearly impermeable waterproof barrier provides excellent protection against moisture – a critical feature for the Pacific Northwest’s wet climate, where freeze-thaw cycles are a common threat to concrete surfaces.

One of the biggest drawbacks of epoxy is its tendency to become brittle in cold weather. Penntek Evolution, however, stays flexible even at temperatures as low as 40°F, enabling it to endure over 300 freeze-thaw cycles without losing its integrity. Installation is quick and hassle-free, often completed in just a single day. Plus, it comes with a lifetime warranty that covers peeling, cracking, and UV-related damage. These qualities make it a durable and low-maintenance choice for protecting concrete in regions with wet and cold conditions.

Related Blog Posts

- Protect Concrete from Salt Damage

- Impact Resistance in Harsh Climates: Polyurea Benefits

- Preventing Moisture-Related Coating Failures

- How Moisture Affects Concrete Coating Performance