Garage Cabinet Installation: Step-by-Step Guide

December 15, 2025

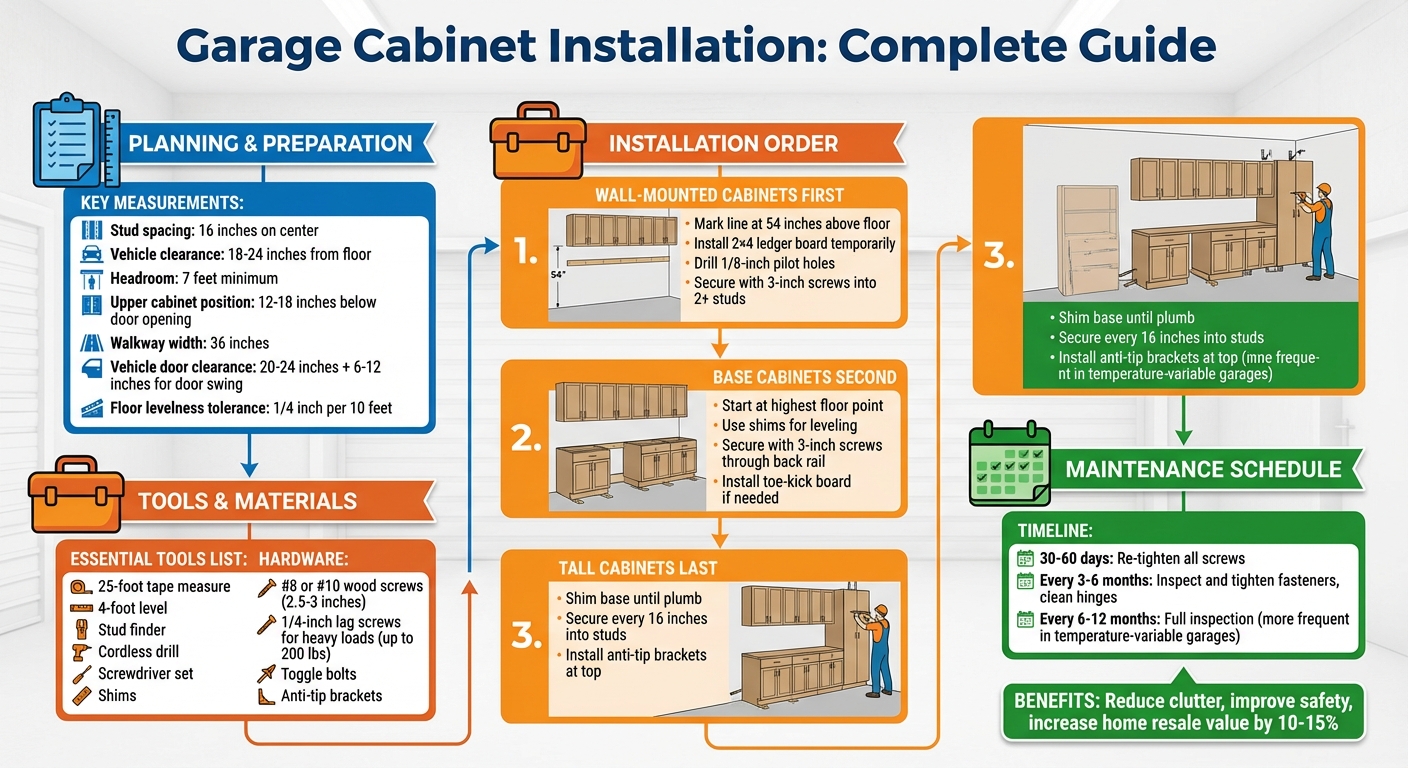

A well-organized garage starts with proper cabinet installation. This guide breaks down everything you need to know to install garage cabinets efficiently, from planning and measuring to securing them in place. Whether you’re tackling this as a DIY project or considering professional help, these steps will help you create a safer, more functional space while maximizing storage.

Key Takeaways:

- Benefits: Garage cabinets reduce clutter, improve safety, and can increase home resale value by 10–15%.

- Preparation: Measure your space, locate wall studs, and plan your layout for optimal storage and vehicle clearance.

- Installation Steps:

- Mount wall cabinets first using studs for support.

- Install base cabinets, ensuring they are level and aligned.

- Secure tall cabinets with anti-tip brackets for added safety.

- Tools Needed: Tape measure, stud finder, level, drill, screws, shims, and safety goggles.

- Maintenance: Regularly inspect and tighten screws, adjust hinges, and clean surfaces to keep cabinets functional and secure.

By following these steps, you can transform your garage into an organized, efficient space. For added durability, consider protecting your floors with high-quality coatings like the Penntek Evolution system.

Garage Cabinet Installation Process: Planning Through Maintenance

Installing Pre-fab Garage Cabinets and Storage

Planning and Preparation

Before diving into the installation, take the time to measure and plan your layout carefully. Start by clearing out the garage area where the cabinets will be installed – this means moving vehicles, boxes, and anything leaning against the walls. Use a magnetic or electronic stud finder to locate studs, marking their positions every 16 inches on center. If needed, verify these locations with a small pilot hole. To visualize your layout, apply painter’s tape to outline cabinet footprints and ensure you account for vehicle door clearance. These steps lay the groundwork for accurate measurements and secure installation, as detailed below.

Measuring and Designing Your Layout

Begin by documenting the dimensions of each wall and creating a scaled layout. Take note of any obstacles, such as doors, windows, electrical outlets, water heaters, or garage door tracks. To ensure sufficient clearance for vehicles, leave at least 18–24 inches between the cabinet bottoms and the floor, and maintain 7 feet of headroom for the garage door to operate smoothly. Upper cabinets should be positioned 12–18 inches below the door opening, which is typically 7–8 feet high.

For maximum efficiency, mount wall cabinets (usually 12–16 inches deep) above workbenches to make the most of vertical space. Base cabinets, which are usually 18–24 inches deep, should be placed along walls while maintaining 36-inch walkways for easy movement. When planning around parked vehicles, leave 20–24 inches of clearance between the cabinet fronts and the stopping point of your car, plus an additional 6–12 inches to accommodate door swings. This level of detailed planning ensures a smooth transition to the installation process.

Inspecting Walls, Floors, and Coatings

Once your layout is finalized, inspect your garage’s walls and floors to confirm they can support the cabinets. Most garages have drywall over wood studs, but some may feature concrete block or metal framing. Tap on the walls to identify hollow versus solid areas, and use a stud finder to mark stud centers every 16 inches. If your walls are concrete, you’ll need masonry anchors instead of standard wood screws.

Check the floor for levelness using a 4-foot level, measuring multiple spots across the space. If you find slopes exceeding 1/4 inch per 10 feet, plan to use shims during installation. For garages with durable floor coatings, like Croc Coatings‘ Penntek Evolution system (which is four times stronger than epoxy), protect the surface by placing cardboard or moving blankets under your work area. When installing base cabinets, use adjustable leveling feet and always lift them into place to avoid scratching the coating.

Tools and Materials Needed

After completing your measurements and inspections, gather the tools and materials you’ll need. Here’s a list of essentials:

- 25-foot tape measure

- 4-foot level

- Stud finder

- Cordless drill with 1/8-inch pilot bits

- Screwdriver set

- Pencil and utility knife

- Shims

For hardware, stock up on #8 or #10 wood screws (2.5–3 inches long for studs), a 2×4 lumber ledger board for temporary support, cabinet clamps, and toggle bolts for areas without studs. If you’re mounting heavy cabinets (up to 200 pounds), use 1/4-inch lag screws to secure them into studs. A laser level can help with precision, and a rubber mallet is useful for fine-tuning adjustments during leveling. Lastly, always wear safety goggles when drilling or assembling to protect your eyes.

With everything in place, you’re ready to move forward with confidence and precision.

Step-by-Step Installation

With your planning complete and materials ready to go, it’s time to start installing. Begin with wall-mounted cabinets, then move on to base cabinets, and finish with tall units. Following this order helps you avoid working over installed base cabinets and ensures better alignment.

Installing Wall-Mounted Cabinets

Start by marking a horizontal reference line for the bottom of your wall cabinets. This line is typically 54 inches above the floor, allowing enough clearance for a standard workbench and easy reach. Use a 4-foot level or a laser level to extend this line across the wall.

Next, temporarily secure a 2×4 ledger board along the level line by screwing it into the wall studs. This will support the cabinets while you work. Place the first cabinet on the ledger, check that it’s level, and drill 1/8-inch pilot holes through the cabinet’s back rail into the stud centerlines you marked earlier. Then, drive 3-inch #10 wood screws or lag screws through the back rail into at least two studs for solid support.

When adding the next cabinet, clamp it to the first one before fastening. Pre-drill, then join the cabinets with shorter screws through their sides. Once secured together, attach each cabinet to the studs independently. After all wall cabinets are installed, remove the ledger board and check that the doors and shelves open and close smoothly.

Installing Base Cabinets

With the wall cabinets in place, move on to the base cabinets. Start by marking a level line on the wall to indicate the top height of the base units. Begin at the highest point of the floor, as this will determine the baseline for leveling. Place the first base cabinet at this high point and use shims under the corners and midpoints until the top aligns with your marked line. Use a level to check both front-to-back and side-to-side alignment. Many modular systems come with adjustable legs, which can make this step easier.

As you add more base cabinets, clamp them together at the face frames to ensure a seamless fit. Level each unit to match the height of the first cabinet, then secure them to the wall by driving 3-inch or longer structural screws through the upper back rail into the studs – using at least two screws per cabinet. If the floor slopes significantly, use a toe-kick board or trim to cover any large gaps created by shims. This not only improves appearance but also protects against moisture and debris. Always secure cabinets into studs or use masonry anchors for concrete walls; avoid relying on drywall alone for support.

Installing Tall Cabinets and Final Adjustments

Once the wall and base cabinets are installed, move on to the tall units. Shim the base of the tall cabinet until it’s perfectly plumb, then clamp it to the adjacent cabinets for proper alignment. Secure the cabinet by fastening the top and bottom back rails into studs every 16 inches. For added stability, especially in earthquake-prone areas or homes with children, install anti-tip brackets at the top, anchoring them into ceiling joists if possible.

After all the cabinets are mounted, check that doors and drawers open and close smoothly. Adjust hinges and drawer slides as needed. If your floor has a professional coating – like the Penntek Evolution system from Croc Coatings – ensure that cabinet feet or shims aren’t scratching the surface. Also, seal any gaps to prevent moisture from wicking into the cabinet bases.

sbb-itb-a0e5ae3

Finishing Touches and Maintenance

Once your cabinets are installed, it’s important to confirm their stability and load capacity. Use a 24-inch or 48-inch level to check that both wall and base cabinets remain plumb and level under their own weight. Gradually load the shelves with your garage items, making sure the weight is distributed evenly. Test doors and drawers while the cabinets are loaded to ensure hinges and slides operate smoothly without sagging or sticking. For tall or freestanding units, double-check that anti-tip brackets are securely anchored to wall studs or ceiling joists. This step is especially crucial to prevent tipping hazards, particularly in homes with children or pets.

Safety Checks and Load Testing

Within the first 30–60 days after installation, re-tighten all mounting screws to account for settling. After that, plan regular inspections every 6–12 months. During these checks, ensure all fasteners remain tight and free of rust. Open and close each door and drawer, listening for squeaks or grinding noises. If you notice play or sag, tighten hinge screws and drawer-slide screws. In garages with large temperature swings, consider inspecting every six months, as expansion and contraction can loosen fasteners over time. Replace stripped screws with slightly longer or thicker ones to ensure a secure hold. If fasteners spin in drywall, relocate them into studs or use proper anchors for full support.

Once stability is confirmed, it’s time to protect your garage floor and surfaces.

Protecting Floors and Coated Surfaces

If your garage floor has a professional coating – like the Penntek Evolution system from Croc Coatings – take extra precautions to preserve its finish. Use soft-wheel dollies or furniture sliders when moving cabinets to avoid scratching or gouging the surface. Never drag metal cabinet feet directly across the coating. After installation, place rubber or vinyl pads under cabinet feet to protect the floor. Clean up any dust or metal shavings with a soft broom or shop vacuum, then mop with a pH-neutral cleaner approved for your floor coating. Avoid harsh acidic or alkaline cleaners, as these can dull the finish over time and reduce slip resistance.

With your floors protected, focus on keeping your cabinets in top condition.

Maintenance Tips

Every 3–6 months, inspect and re-tighten mounting screws, shelf pins, and connector bolts, especially if your cabinets bear heavy loads or are exposed to vibrations from garage doors or equipment. Adjust concealed hinges seasonally to keep doors aligned and functioning smoothly. Twice a year, clean hinges and drawer slides, applying a light, approved dry lubricant for smooth operation.

For melamine or laminate cabinets, wipe them down with a soft cloth or sponge using warm water and mild dish soap. Avoid abrasive cleaners or pads that could scratch the surface or damage edge banding. For painted or powder-coated steel cabinets, clean with a non-abrasive cleaner and microfiber cloth to avoid scratching the finish. Promptly wipe up spills of automotive fluids, fertilizers, or chemicals from both cabinets and floors to prevent staining or corrosion.

Regular maintenance ensures your cabinets stay functional and looking great for years to come.

Conclusion

Adding garage cabinets can turn a messy, chaotic space into an organized and functional area. By sticking to the steps outlined here – measuring accurately, ensuring everything is level and plumb, and securely attaching the units to wall studs – you can achieve a polished, professional look.

The secret to long-term success lies in those finishing touches, like thorough safety checks and regular maintenance. As mentioned earlier, periodic inspections and proper cleaning will keep your cabinets in great shape for years to come.

A well-done installation sets the stage for a lasting improvement to your garage. If you’re aiming to maximize the value of this space, consider pairing high-quality cabinets with a durable floor coating. For instance, Croc Coatings offers the Penntek Evolution system, known for its impressive durability – four times stronger than epoxy – and its quick, one-day installation process. Backed by a lifetime warranty, their team has successfully completed over 1,000 installations across North Idaho, Spokane, and the Tri-Cities. With more than 300 five-star reviews, they’ve earned a reputation for professionalism and attention to detail.

"The installation team was professional and you could see the pride they took in their work. Highly recommend the product and the company’s customer service." – Leon Marshall

Whether you decide to install the cabinets yourself or bring in professionals like Croc Coatings for custom cabinets and flooring, the end result is a garage that’s cleaner, safer, and adds value to your home. For a free in-home estimate, call 208-244-0694.

FAQs

What mistakes should I avoid when installing garage cabinets?

To set up your garage cabinets like a pro, steer clear of these frequent pitfalls:

- Skipping measurements: Accurate measurements are non-negotiable. Without them, you risk cabinets that don’t align properly, wasting both time and effort.

- Neglecting leveling: Uneven cabinets don’t just look bad – they can also mess with their functionality.

- Rushing the process: Slow down and follow each step methodically. A little patience goes a long way toward a polished, professional finish.

- Ignoring manufacturer instructions: Those instructions exist for a reason. Stick to them to avoid unnecessary mistakes.

- Using the wrong tools: The right tools make all the difference, ensuring a smoother installation and a secure fit.

- Improper wall anchoring: Skimping on wall anchoring can lead to unstable cabinets or even damage. Make sure they’re firmly secured.

Taking the time to plan carefully and avoid these missteps will leave you with sturdy, well-installed cabinets that stand the test of time.

What’s the best way to securely mount garage cabinets to concrete walls?

To securely attach garage cabinets to concrete walls, you’ll need heavy-duty masonry anchors or wall anchors made for concrete surfaces. Begin by drilling pilot holes using a hammer drill equipped with a masonry bit, making sure the holes match the size of your anchors. After inserting the anchors, secure the cabinet mounting brackets with strong screws to ensure stability and durability. Don’t forget to check the alignment and confirm the weight capacity to keep everything safe and secure.

How can I maintain my garage cabinets to keep them looking great and functioning well?

To keep your garage cabinets looking great and functioning well, make regular cleaning a habit. Use mild soap and water to wipe them down, steering clear of harsh chemicals that might harm the finish. Be on the lookout for signs of wear, like loose hinges or scratches, and fix these issues as soon as you notice them. Good ventilation is key during cleaning to avoid moisture buildup, which can cause mold or even warp the cabinets over time. If your cabinets have a protective coating, don’t forget to reapply it when necessary to maintain their durability.

Related Blog Posts

- Ultimate Guide to Garage Space Optimization

- Custom Garage Cabinets vs DIY Shelves

- How to Budget for Custom Garage Cabinets

- Custom Garage Cabinets: Installation Tips for Beginners