Epoxy Garage Floors: Pros and Cons

January 1, 2026

Epoxy garage floors are a popular choice for protecting and upgrading concrete surfaces. They offer durability, resistance to stains, and a polished look. However, newer options like polyaspartic floor coatings may provide better long-term performance. Here’s a quick breakdown:

- Epoxy Flooring: Costs $3–$6 per sq. ft., lasts 10–20 years (under ideal conditions), but may crack or yellow over time. Installation takes several days.

- Penntek Evolution System: Costs $7–$9 per sq. ft., lasts 15+ years, resists UV damage, and handles freeze-thaw cycles. Installation is completed in one day. Proper preparation for a 1-day floor coating is essential for a successful result.

Key Takeaway: Epoxy is budget-friendly for standard conditions, while Penntek offers better durability and faster installation for harsher environments. Choose based on your priorities – cost or long-term performance.

Epoxy vs Penntek Evolution System: Cost, Durability & Performance Comparison

1. Epoxy Garage Floors

Durability and Performance

Epoxy flooring isn’t just a surface coating; it’s a tough, chemically bonded layer that becomes part of the concrete itself. This bond is created during an exothermic curing process, forming a rigid, durable layer that goes far beyond what paint can achieve. As Hovsep Kourbouchian of Sealtech Floors explains:

Epoxy bonds chemically to the slab, creating a single, non-porous surface that resists impact from dropped tools and vibrations from vehicles.

This seamless, non-porous surface also acts as a shield against common garage contaminants like oil and grease. Built to handle heavy vehicle loads and withstand impacts, epoxy flooring is engineered for strength. However, for a coating to be considered true "epoxy flooring", it must be at least 2 millimeters thick. Anything thinner is categorized as an epoxy floor coating, which lacks the same level of durability.

This impressive strength and resilience highlight the importance of a precise and thorough installation process.

Installation Process

Installing epoxy flooring is a multi-step process that typically takes three days and requires temperatures between 50°F and 90°F for proper curing. The key to a successful installation lies in preparing the surface. Mechanical methods like diamond grinding or shot blasting are used to open up the concrete’s pores, ensuring the epoxy adheres properly.

The process includes three main phases: mechanical surface preparation, applying a primer or base coat (often with decorative flakes), and finishing with a clear topcoat. Once installed, the floor needs time to cure. While foot traffic can resume after 24–72 hours, vehicles should wait at least seven days. As general contractor Tom Silva notes:

It typically takes about seven days for the epoxy and topcoat to cure completely before you can drive on the surface.

Cost and Value

Epoxy flooring offers both performance and financial value. On average, professional installation costs around $2,441 nationwide, with most projects ranging between $1,595 and $3,337. Prices typically fall between $3 and $12 per square foot, with labor making up about 65% of the total cost. Material costs vary: solid epoxy ranges from $45 to $150 per gallon and has a lifespan of 10–20 years, while water-based epoxy costs $30 to $50 per gallon but may need reapplication every 1–3 years. According to Matthew Hage, owner of The Concrete Guy:

The long-lasting durability of epoxy makes it a smart long-term investment for protecting and enhancing a garage space.

Maintenance and Longevity

A professionally installed epoxy floor can last 15–20 years or more, while DIY installations generally hold up for 5–10 years due to differences in materials and preparation techniques. Maintenance is straightforward: regular sweeping and mopping with a pH-neutral cleaner will keep the surface looking great. Avoid using harsh chemicals or power washers, as they can damage the finish.

One thing to watch out for is sunlight exposure. Standard epoxy can yellow or chalk when exposed to direct sunlight, so garages with lots of natural light may need a UV-stable topcoat. Additionally, because epoxy is non-breathable, it’s important to test for moisture vapor transmission in the concrete before installation. High moisture levels can cause bubbling or delamination over time. Proper preparation ensures the floor’s longevity and performance.

sbb-itb-a0e5ae3

Epoxy Flooring: Pros and Cons You Should Consider Before Installation

2. Penntek Evolution System by Croc Coatings

The Penntek Evolution System by Croc Coatings takes flooring solutions to the next level, addressing the common shortcomings of standard epoxy with improved resilience and long-term value.

Durability and Performance

Unlike traditional epoxy, the Penntek system is built to last. It uses a pure polyurea basecoat that forms a chemical bond with concrete, delivering 98% more elongation and 10 times the flexibility of epoxy. This flexibility allows it to handle freeze–thaw cycles without cracking or peeling. Croc Coatings explains:

"Epoxy keeps curing year after year so as it continues to harden, the movement of the concrete below eventually forces the coating to break free causing peeling, chipping and ultimately failure."

Polyurea cures completely within 48 hours and retains its flexibility for over 15 years, far exceeding the typical 2–5 year lifespan of epoxy. Additionally, it resists UV damage without yellowing and tolerates heat up to 266°F. To back up these claims, Croc Coatings offers a 15-year manufacturer’s warranty.

Installation Process

The Penntek system is designed for efficiency, with professional installation completed in just one day. Industrial grinders are used to create a Concrete Surface Profile (CSP) of 3–4, while tools like the Tramex CMEX5 moisture meter ensure proper moisture levels before application. Floors are walkable within 24 hours and fully cured in 48 hours. One notable installation highlighted the system’s ability to perform reliably even in challenging conditions, showcasing its practicality and quick turnaround time.

Cost and Value

The Penntek Evolution System costs approximately $7 to $9 per square foot, compared to the $3 to $6 per square foot price range for standard epoxy. While the upfront cost is higher, its extended lifespan – lasting over 15 years compared to epoxy’s 2–5 years – offers considerable value over time.

Maintenance and Longevity

Keeping the Penntek-coated floor looking great is simple: regular sweeping and mopping with pH-neutral cleaners are all that’s needed. Its slip-resistant surface adds an extra layer of safety, making it ideal for garages and workshops. Unlike epoxy, which hardens and becomes brittle over time, the Penntek coating flexes with the concrete, ensuring both durability and visual appeal for years to come.

Advantages and Disadvantages

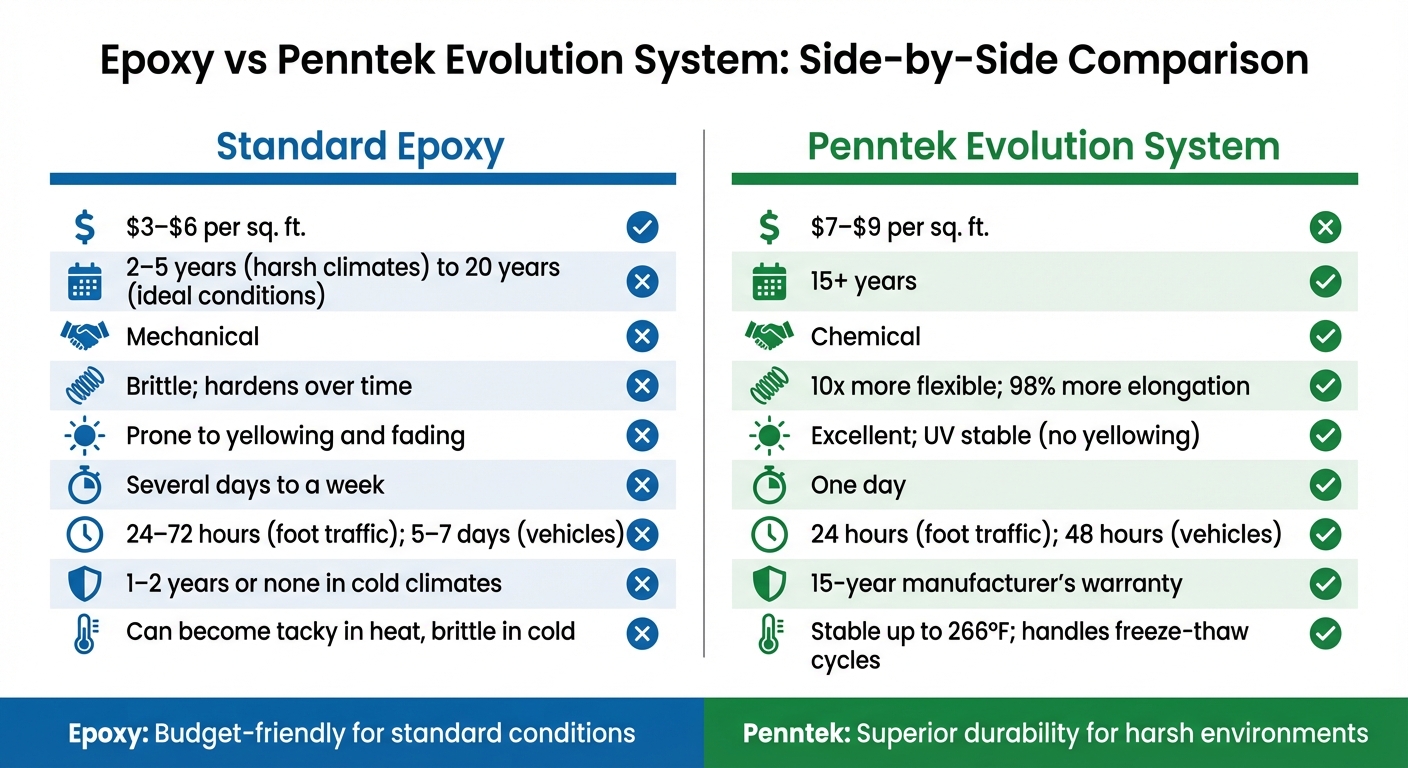

Here’s a breakdown of how standard epoxy compares to the Penntek Evolution System in terms of cost, durability, and performance. The table below highlights their key differences.

Standard epoxy is an economical option, costing about $3 to $6 per square foot, which makes it appealing for homeowners looking to save money. It provides a smooth, polished finish and, with routine maintenance like sweeping and using pH-neutral cleaners, it can hold up reasonably well. However, epoxy relies on a mechanical bond and continues to harden over time, which can make it susceptible to cracking – especially in areas with freeze-thaw cycles. Its lifespan ranges from 2 to 5 years in harsh environments but can stretch up to 20 years in ideal conditions. That said, it does have some downsides: exposure to UV light can cause yellowing, extreme heat may leave the surface sticky, and cold temperatures can make it brittle.

The Penntek Evolution System, on the other hand, uses a chemical bond that is significantly more flexible – 10 times more so than standard epoxy – and offers 98% greater elongation. This flexibility helps prevent peeling and cracking. It also resists UV damage without yellowing, withstands temperatures as high as 266°F, and holds up well in freeze-thaw conditions. With a lifespan of over 15 years, backed by a 15-year manufacturer’s warranty, it’s a long-term solution. Installation is quick, taking just one day, with a full cure in 48 hours, compared to the multi-day process often required for epoxy. While Penntek costs more at $7 to $9 per square foot, its durability and lower maintenance needs make it a worthwhile investment for those seeking a long-lasting option.

| Feature | Standard Epoxy | Penntek Evolution System |

|---|---|---|

| Cost per sq. ft. | $3–$6 | $7–$9 |

| Lifespan | 2–5 years (harsh climates) to 20 years (ideal) | 15+ years |

| Bond Type | Mechanical | Chemical |

| Flexibility | Brittle; hardens over time | 10x more flexible |

| UV Resistance | Prone to yellowing and fading | Excellent; UV stable |

| Installation Time | Several days to a week | One day |

| Cure Time | 24–72 hours (foot traffic); 5–7 days (vehicles) | 24 hours (foot traffic); 48 hours (vehicles) |

| Warranty | 1–2 years or none in cold climates | 15-year manufacturer’s warranty |

| Temperature Tolerance | Can become tacky in heat, brittle in cold | Stable up to 266°F; handles freeze-thaw cycles |

If you’re looking for a budget-friendly, short-term solution, epoxy might work for you. But if long-term durability and performance are priorities, the Penntek Evolution System is the better choice.

Conclusion

If you’re working on a budget and need a coating for standard conditions, epoxy is a solid choice. But if you’re looking for something that cures quickly and offers exceptional durability, Penntek is the way to go.

Epoxy performs well in climate-controlled spaces, like garages with minimal UV exposure. When installed by professionals, it offers dependable protection at a lower upfront cost. However, for areas exposed to harsh conditions or when you need a quick turnaround, the Penntek Evolution System provides better long-term value. While the initial cost is higher, its benefits – like flexibility, UV resistance, and faster installation – help minimize future maintenance needs.

To break it down: epoxy is an affordable option but requires careful consideration of the environment. On the other hand, Penntek’s advanced formula overcomes many of the challenges associated with traditional coatings, delivering practical perks like reduced downtime, fewer repairs, and longer-lasting results.

Croc Coatings specializes in installing the Penntek Evolution System. Their certified teams ensure surfaces are properly prepared and applied for maximum durability.

If your priorities include durability, quick use, and long-term peace of mind, the Penntek Evolution System is the clear winner. For those prioritizing cost over longevity, epoxy remains a practical, though higher-maintenance, alternative.

FAQs

How does epoxy compare to the Penntek Evolution System in terms of durability and performance?

Epoxy coatings are known to last around 2 to 5 years before wear and tear start to show – think oil stains, UV fading, or cracking. On the other hand, the Penntek Evolution System, a polyurea-based coating, is built to last. It’s 4x stronger than epoxy and, with proper installation and maintenance, it can hold up for 15 years or more.

What sets the Penntek Evolution System apart is its flexibility, resistance to chemicals, and ability to handle heat. It tolerates temperatures as high as 266°F (and short-term exposure up to 430°F) without cracking, unlike epoxy, which is more vulnerable to heat damage. If durability and longevity are what you’re after for your garage floor, the Penntek Evolution System is designed to handle the toughest challenges with ease.

What’s the difference between installing epoxy flooring and the Penntek Evolution System?

Epoxy flooring involves a detailed, multi-step process that can stretch over several days. It starts with cleaning, degreasing, and mechanically etching the concrete to ensure the coating adheres properly. Then, multiple layers are applied: a base coat, optional decorative flakes, and a clear topcoat. Each layer requires 12–24 hours to cure, and cooler weather can extend this time. The process also produces strong fumes, so proper ventilation and protective gear are a must.

On the other hand, the Penntek Evolution System, offered by Croc Coatings, simplifies everything with a one-day application. After preparing the surface with cleaning and light shot-blasting, a proprietary coating is applied in a single layer. This coating chemically cures in just hours, skipping the need for multiple layers. Even better, your garage floor can be ready to use the same day. The Penntek system is also designed to be 4x stronger than traditional epoxy, making it a tough, efficient solution for your garage.

Why might someone choose epoxy flooring instead of the Penntek Evolution System for their garage?

Epoxy flooring is a popular choice for homeowners because it’s generally more budget-friendly upfront and can be installed as a DIY project. This makes it especially appealing to those who are mindful of costs or enjoy tackling home improvement projects themselves. Plus, epoxy flooring comes in a wide range of colors and finishes, making it easy to customize and align with personal style preferences.

While the Penntek Evolution System stands out for its durability and high performance, epoxy’s affordability and simple application process make it an attractive option for anyone focused on saving money or seeking a quick, personalized flooring solution.

Related Blog Posts

- Polyurea vs. Epoxy: Eco-Friendly Garage Floor Options

- Top 3 Benefits of Polyurea for Garage Floors

- Short-Term vs Long-Term Costs of Garage Floor Coatings

- Polyurea vs. Epoxy: Warranty and Cost Differences