How to Check Concrete Coating Adhesion

January 20, 2026

Adhesion testing ensures your concrete coatings stick properly, preventing peeling, blistering, and costly repairs. Without a strong bond to the surface, even high-end coatings fail. Here’s what you need to know:

- Why it matters: Concrete has low tensile strength (400–500 psi), so adhesion testing confirms the coating bond is strong enough to handle wear, chemicals, and moisture.

- Where it’s critical: High-traffic areas like garages, industrial floors, patios, and basements.

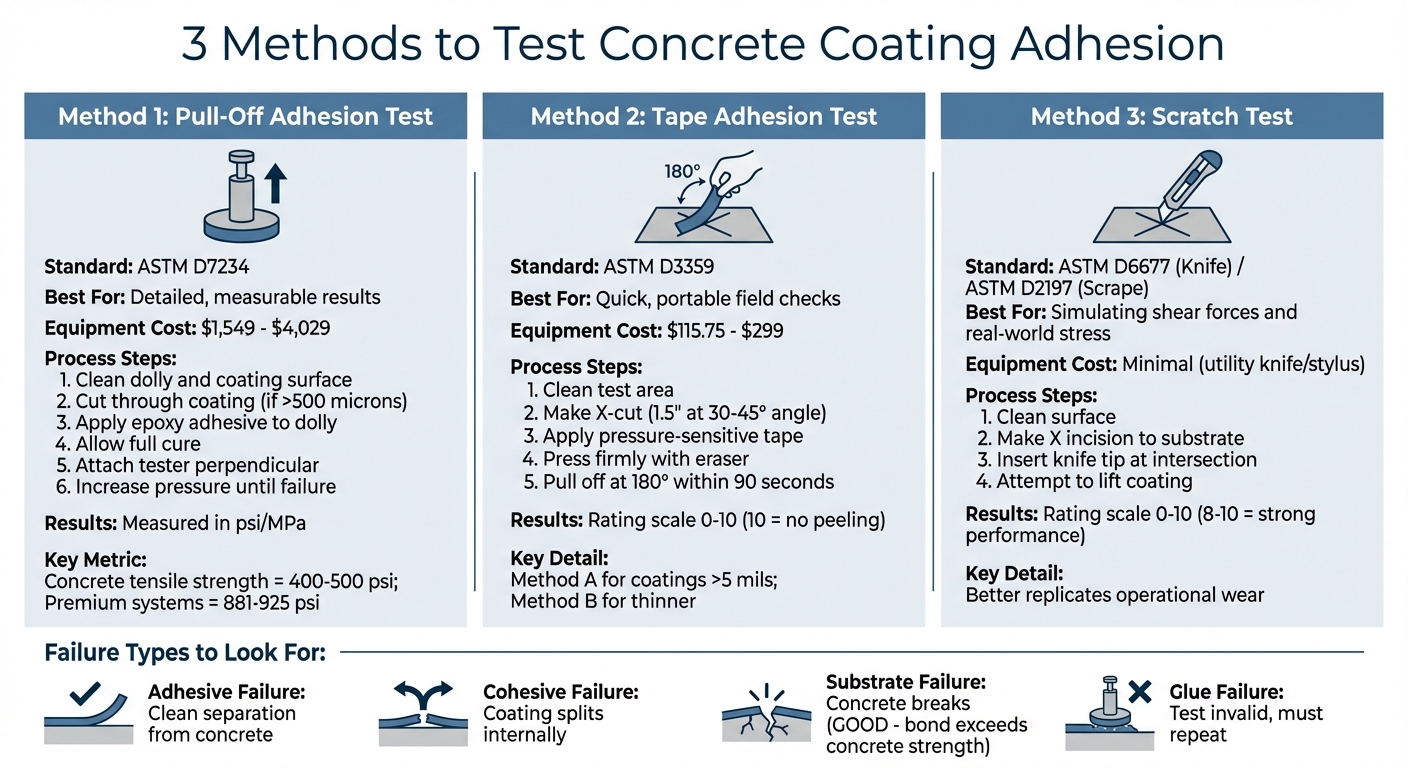

- Methods:

- Pull-off test: Measures tensile strength using a dolly and tester.

- Tape test: Quick, portable method for surface adhesion checks.

- Scratch test: Simulates shear forces to assess durability.

- Tools needed: Pull-off testers ($1,549–$4,029), dollies ($145–$195), and epoxy adhesive ($30).

- Standards: Follow ASTM D7234 (pull-off) and ASTM D3359 (tape) for reliable results.

If results fall below expectations or are inconsistent, consult professionals to diagnose issues like poor surface preparation or improper curing. Testing ensures your coating lasts and performs as intended.

8. How to Measure the Pull-Off Adhesion of Coatings on Concrete

Tools and Materials Required

Getting ready for adhesion testing? Make sure you have the right tools and materials to get accurate and dependable results. Most tests don’t require much – just a few key items.

Testing Equipment

The cornerstone of any adhesion test is a pull-off adhesion tester. These portable devices apply controlled tensile force to gauge how well a coating sticks to concrete. A few popular models include:

- Elcometer 106: A mechanical tester that needs annual calibration.

- Hydraulic HATE model: A hydraulic option for precise measurements.

- Air-energized PATTI: Uses a conversion chart for readings.

- Self-aligning hydraulic PosiTest AT: Known for its ease of use.

Manual testers like the Elcometer 106/6 are priced around $1,549.00, while automated models such as the Elcometer 510 range from $3,409.00 to $4,029.00.

For these tests, you’ll need 50 mm (2-inch) diameter dollies, which are metal fixtures that define a consistent test area. This size helps account for the uneven nature of concrete. A set of five dollies costs between $145.00 and $195.00, and pre-blasted versions offer better adhesion. To attach the dolly to the coating, use a high-strength two-part epoxy adhesive like Araldite or Hardman Double Bubble, which costs about $30.00 for a 15 ml kit. To isolate the test area, invest in a dolly cutter (around $165.00, with an additional $49.00 for the handle). Before applying adhesive, roughen both the dolly and coating surface using 100-grit or finer sandpaper for better results.

For simpler field tests, you can use pressure-sensitive tape (per ASTM D3359 standards), a sharp utility knife or razor blade, and a metal straightedge to create cross-hatch patterns. Cross-cut guide kits cost between $115.75 and $299.00, and a soft brush is handy for clearing away loose particles. If you need a quick check, a rounded stylus or utility knife can be used for scrape or knife adhesion tests. Always follow established standards to ensure your results are reliable.

Industry Standards and Compliance

Sticking to established testing protocols ensures your results are consistent, repeatable, and credible. ASTM D7234 is the go-to standard for testing coatings on concrete, outlining proper pull-off testing methods. It specifies that the load rate shouldn’t exceed 30 psi per second, and tests should ideally take between 5 to 30 seconds. While ASTM D4541 was initially created for metal surfaces, it’s often used for portable testers and can be adapted for rigid substrates.

"The 50mm diameter loading fixture size accommodates testing over a more representative surface area, since concrete can be non-homogeneous." – KTA University

For tape testing, ASTM D3359 provides guidelines, with Method A for coatings thicker than 125 μm (5 mils) and Method B for thinner coatings. Additionally, ASTM D6677 covers knife adhesion assessments. Keep your equipment calibrated – either as per the manufacturer’s guidelines or at least every three years – to maintain accuracy. When documenting results, include details about the equipment used, as different tools may produce varying data. This step is essential for quality control and warranty compliance.

How to Perform Adhesion Tests

Concrete Coating Adhesion Testing Methods Comparison Chart

Adhesion tests are crucial for ensuring your concrete coating can withstand tough conditions. Each method offers unique insights: pull-off tests provide detailed, measurable results; tape tests are quick and portable; and scratch tests simulate real-world stress.

Pull-Off Adhesion Test

Start by thoroughly cleaning both the dolly and the coating surface to eliminate dust or grease. For coatings thicker than 500 microns (20 mils), cut through to the substrate to avoid interference from lateral bonding. Mix a two-part epoxy adhesive, apply it to the dolly, and press firmly. Allow the adhesive to fully cure for accurate results.

Once cured, attach the tester perpendicular to the surface and gradually increase the pressure until the coating fails. The tester will record the maximum force in psi or MPa. After testing, examine the fracture surface. If the concrete itself fractures (substrate failure), it’s a strong sign that the coating bond exceeds the concrete’s natural tensile strength. For instance, in October 2021, Slide-Lok chemist Samuel Strayer used a DeFelsko PosiTest AT-A to test primer systems on diamond-ground concrete. A waterborne acrylic sealer failed at an average of 321 psi (adhesive failure), while a waterborne epoxy primer achieved 881 psi (substrate failure), significantly reinforcing the concrete beyond its original strength.

"Failure will occur along the weakest plane within the system comprised of the loading fixture, glue, coating system, and substrate, and will be exposed by the fracture surface." – ASTM International

For a faster, more portable option, consider the tape test.

Tape Adhesion Test

The tape test, defined by ASTM D3359, comes in two variations: Method A (X-cut) for coatings over 5 mils (125 µm) and Method B (Cross-cut) for thinner coatings. Begin by cleaning the test area and, if necessary, removing any chalky residue from the surface.

Using a sharp tool, make two 1.5-inch cuts at a 30° to 45° angle that intersect to form an "X." Ensure the cuts go through all coating layers down to the substrate in one smooth motion. Apply pressure-sensitive tape over the cuts, pressing it firmly with a pencil eraser. Within 90 seconds (± 30 seconds), pull the tape off quickly at a 180° angle. Assess the coated surface (not the tape itself) and rate adhesion on a scale from 0 to 10, where 10 means no peeling and 0 indicates significant removal beyond the cuts.

"Experience has shown that high pull-off adhesion values can be achieved on a coating system that is easily lifted with a knife, tape or in some cases one’s fingers. This is primarily due to the directional forces applied to the coating system during the tests." – Raymond Tombaugh, Senior Coatings Consultant, KTA-Tator, Inc.

To evaluate shear forces, move on to the scratch test.

Scratch Test

Scratch tests measure how well a coating withstands shear or peel forces, mimicking real-world stress more closely than tensile tests. Start with the Knife Test (ASTM D6677). After cleaning the surface, use a sharp utility knife to make an "X" incision through the coating to the substrate. Insert the knife tip at the intersection and try to lift the coating. Rate adhesion on a scale from 0 to 10, with 8 to 10 indicating strong performance.

For the Scrape Test (ASTM D2197), use a rounded stylus and gradually increase the pressure as you drag it across the coating until it detaches. This test simulates operational wear and further demonstrates coating durability. It’s common for the substrate to fail before the coating does.

"The shear tests are oftentimes more definitive because they better replicate the way in which coatings fail." – KTA University

sbb-itb-a0e5ae3

How to Read and Record Test Results

After running the tests, the next step is to interpret the results and document them accurately. This involves closely examining the fracture surface to pinpoint the weakest link in the coating system.

Types of Coating Failure

The fracture surface provides key insights into where the system failed.

Adhesive failure happens when the coating separates cleanly from the concrete surface. In this case, the dolly face will appear smooth with little to no concrete residue, and the substrate will show no leftover coating or crater. This type of failure usually points to issues like inadequate surface preparation or material incompatibility.

Cohesive failure occurs within the coating layer itself. Here, both the dolly and the substrate will retain coating material, signaling that the bond to the substrate is stronger than the coating’s internal strength.

Substrate failure is when the concrete itself breaks before the coating bond does. This will leave rough concrete chunks on the dolly face and a visible crater in the substrate. Surprisingly, this is a good sign – it means the coating bond exceeds the concrete’s natural tensile strength, which typically ranges from 400 psi to 500 psi.

"The face of the dolly and the pull location tell a story unique to each adhesion pull. It is important to evaluate each individual pull to determine if the failure point is at the substrate, within the coating itself or at the glue/dolly interface." – Samuel Strayer, Chemist, Slide-Lok

Glue failure invalidates the test. If the dolly face is clean or only shows adhesive residue while the coating remains intact, the glue bond failed. For "Test to Fracture" protocols, if glue failure affects more than 25% of the loading fixture area, the results must be discarded, and the test repeated.

Once you’ve identified the failure mode, it’s time to document the findings thoroughly.

Recording Test Data

Accurate record-keeping is essential for performance tracking and meeting project requirements. Start by noting the tester model, as results can vary between devices and aren’t directly comparable.

Key details to record include:

- Pull-off strength in psi or MPa

- Failure mode, expressed in percentages (e.g., 80% cohesive in concrete, 20% adhesive)

- Environmental conditions during testing, such as temperature and humidity, as these can affect bond strength

- Glue type, cure time, and pull rate (keep it under 30 psi per second for concrete substrates)

To ensure reliable data, perform at least three replicate tests in each designated area. A simple table format can help organize this information, with columns for test location, pull-off strength, failure mode, and pass/fail status based on your project’s criteria.

Comparing Results to Industry Standards

To evaluate your results, use ASTM D7234 for pull-off strength on concrete and ASTM D3359 for tape adhesion ratings. Concrete generally has a tensile strength between 400 psi and 500 psi, so substrate failures above this range indicate strong coating performance.

High-performance primers, such as waterborne or 100% solids epoxy, can significantly enhance substrate strength. For example, in comparative studies, acrylic sealer primers failed at an average of 321 psi – about 64.3% lower than the pull-off strength of epoxy or polyaspartic systems. Premium systems often achieve substrate failures between 881 psi and 925 psi, reinforcing the concrete far beyond its original capacity.

"When testing in a specific location, the highest results obtained may be the most representative. The most common errors made during the testing process lead to artificially lower results, typically not higher results." – ASTM D4541 (Note 11)

Before testing, confirm that the coating has fully cured according to the manufacturer’s recommendations. Testing too early can result in artificially low cohesive strength readings. For projects with strict performance standards, consider using Protocol 2 (Pass/Fail) testing.

When to Call a Professional

While DIY adhesion testing can offer helpful insights, there are times when professional expertise is not just beneficial but necessary. If your tests fall short of required standards or you notice visible issues like peeling, blistering, or delamination, it’s a clear sign that the coating hasn’t bonded properly to the concrete. Attempting unauthorized repairs in such cases can often make the problem worse. Additionally, if your test results are inconsistent or unclear, it’s best to call in a professional for a thorough evaluation.

Determining the exact cause of failure often requires specialized knowledge. Factors like excessive moisture, improper surface porosity, or extreme application conditions (such as high humidity or temperature) can undermine adhesion in subtle ways that aren’t immediately obvious.

"Adhesion testing isn’t just an option – it’s a necessity that ensures your concrete coatings deliver long-lasting performance and durability. Of course, partnering with experienced professionals will be a great help." – Sealwell Inc

For one-time projects, the cost of industrial-grade pull-off adhesion testers – designed to meet ASTM D7234 standards – can be prohibitive. Plus, these tests are inherently destructive, leaving a small "plug" where the coating detaches. Professionals are skilled at performing these tests strategically and can make immediate spot repairs to preserve the integrity of your flooring.

Advantages of Professional Inspection

Professional inspectors bring more than just tools – they bring precision. Using self-aligning testers, they can achieve more reliable pull-off values compared to manual or fixed-alignment methods. For instance, if a "glue break" affects more than 25% of the test area, professionals will typically discard the result and retest to ensure the data accurately reflects the coating’s true strength.

Beyond testing, experts assess whether the concrete surface was properly prepared before coating application. Poor surface preparation is one of the leading causes of adhesion failure. They also confirm that the coating has had sufficient time to cure according to the manufacturer’s guidelines, avoiding artificially low test results caused by premature testing.

Contact Croc Coatings

If your adhesion testing reveals issues that DIY methods can’t address, it’s time to seek professional help. For residents in North Idaho and Eastern Washington – including Spokane and the Tri-Cities – Croc Coatings offers expert evaluations and durable solutions. Their Penntek Evolution industrial coating system is 4x stronger than epoxy and backed by a lifetime warranty. With a one-day installation process, Croc Coatings can upgrade garage floors, patios, pool decks, basements, and industrial spaces efficiently. Led by founders Jim and Kelley Hobart, their certified team ensures all installations meet ASTM standards, delivering lasting performance and reliability.

Conclusion

Testing adhesion is a critical step in ensuring your floors can withstand the challenges of daily use. Without proper testing, there’s no guarantee that the coating will hold up against wear and tear, moisture, or exposure to chemicals. When adhesion fails, issues like common concrete coating defects like peeling, blistering, and delamination can arise – leading to expensive repairs down the line.

For reference, the tensile strength of untreated concrete typically falls between 400–500 psi. However, professional-grade primers can significantly boost this range to 880–925 psi. This highlights why thorough adhesion testing is so important, as it directly impacts the durability and performance of your flooring system.

"Adhesion pull-off strength testing is invaluable in determining the overall quality and integrity of an installed system and its potential performance or lack thereof." – Samuel Strayer, Chemist, Slide-Lok

Key Takeaways

To ensure your flooring system performs as expected, keep these points in mind:

- Adhere to industry standards. Use ASTM D7234 for pull-off tests and ASTM D3359 for tape tests. These methods provide measurable data on bond strength and can reveal potential failure points before they become visible problems.

- Pay attention to curing and conditions. Always allow the recommended cure times, monitor environmental factors, and use the right tools for testing.

- Seek professional help when needed. If your DIY tests show inconsistent results or fail to meet required specifications, it’s best to consult an expert. Companies like Croc Coatings bring specialized equipment and certified expertise to the table, ensuring accurate test results and reliable solutions. For homeowners in North Idaho, Spokane, and the Tri-Cities area, Croc Coatings offers the Penntek Evolution system, which delivers adhesion strength four times greater than traditional epoxy. Plus, it comes with a lifetime warranty against cracking, peeling, and delamination.

FAQs

What’s the difference between pull-off, tape, and scratch tests for concrete coating adhesion?

When evaluating how well a concrete coating sticks to a surface, pull-off, tape, and scratch tests each offer unique insights, depending on the situation and the level of precision needed.

- Pull-off tests: This method gauges the tensile strength of a coating. A metal dolly is glued to the coating, the adhesive is allowed to cure, and then specialized equipment pulls the dolly off. The result is a precise strength measurement in psi, making it perfect for detailed performance assessments. However, it does require more time and specific tools.

- Tape tests: A simpler option, this involves cutting a pattern into the coating, applying tape over it, and then peeling the tape off to observe how much of the coating comes away. While quick and easy to perform, it provides a qualitative result rather than a precise numerical value.

- Scratch tests: By using a blade or knife, this method evaluates how easily the coating can be scratched or damaged. It’s another fast and inexpensive approach, but the results are more subjective compared to the pull-off test.

For precise strength measurements, pull-off tests are the go-to choice. On the other hand, tape and scratch tests are better suited for quick on-site checks or when resources are limited.

How can I check if my concrete coating isn’t adhering properly?

To determine if your concrete coating has lost its adhesion, start with a simple visual check. Watch for peeling, flaking, bubbling, or cracking, especially in areas with heavy foot traffic or along edges and joints. These are telltale signs that the coating may no longer be securely bonded. You can also lightly press the surface with a tool or your fingernail. If you hear a hollow sound or notice separation, it could point to delamination.

For a more accurate assessment, consider using a pull-off adhesion tester or creating a DIY version with a small metal dolly and strong adhesive. If the coating comes off with less than 500 psi of force, it indicates weak adhesion. It’s also wise to check the moisture levels in the concrete using a moisture meter since excessive moisture can undermine the bond.

If you spot any of these issues, make a note of the affected areas and reach out to Croc Coatings. Their experts can conduct thorough testing and provide tailored solutions. Plus, they back their professional installations with a lifetime warranty for added peace of mind.

How do I know when to call a professional for concrete coating adhesion testing?

If you spot visible problems like peeling, bubbling, or cracks in your concrete coating, it might be time to consult a professional. Another red flag is if a pull-off test reveals adhesion strength below 500 psi – this could mean the coating is likely to fail within 2 to 5 years. For added peace of mind and to extend the life of your coating, scheduling professional testing every 6 to 12 months is a smart move.

Related Blog Posts

- Pre-Installation Checklist: Concrete Floor Coating

- Why Adhesion Strength Matters for Concrete Coatings

- Top Abrasion Tests for Concrete Coatings

- How To Assess Concrete Coating Durability