Why Surface Prep Matters for Epoxy and Polyurea Floors

January 4, 2026

Surface prep is the most critical step for durable epoxy floors – 80% of coating failures happen due to poor preparation. Without proper grinding, cleaning, and moisture testing, epoxy won’t bond effectively, leading to peeling, bubbling, and cracking. A well-prepared surface ensures strong adhesion, long-lasting performance, and a smooth finish.

Here’s what you need to know:

- Adhesion depends on prep: Contaminants like oil or grease block bonding, causing delamination and weak spots.

- Moisture testing is essential: Trapped moisture leads to bubbling and peeling.

- Mechanical abrasion is key: Grinding or shot blasting creates the rough texture epoxy needs to grip securely.

- Cracks need repair: Unfixed cracks weaken the floor and show through the epoxy.

Skipping these steps can cost you time and money in repairs. Investing in proper surface prep ensures your floor lasts for decades without failure.

How To Prep Concrete Floors for Epoxy Coating

Problems Caused by Poor Surface Preparation

When surface preparation is neglected, the results can be costly, structurally damaging, and even hazardous. While you can transform your floor with a 1-day floor coating and have it look perfect right after installation, problems often begin to surface within weeks or months. These issues tend to develop gradually, leaving property owners unaware until the damage becomes significant. Below, we delve into how specific problems, like adhesion failures, directly affect the performance and longevity of epoxy floors.

Adhesion Failures

For epoxy to bond effectively, it needs to penetrate the concrete surface and form a strong mechanical connection. However, contaminants such as oil, grease, tar, drywall mud, or old sealers can block this process. When epoxy can’t properly adhere, issues like peeling, delamination, hot tire pick-up, and fish eyes – those small, circular craters that ruin the floor’s appearance – become inevitable. Even tiny traces of silicone or petroleum residue can disrupt adhesion across large sections of the floor. Beyond just adhesion, poor surface preparation weakens the entire structure of the floor, as discussed below.

Structural Weakness

If laitance (a weak, powdery layer) isn’t removed or cracks in the concrete aren’t repaired, the epoxy ends up bonding to a compromised surface. Over time, this weak bond gives way, especially when moisture or contaminants seep underneath. Moisture vapor pressure can build beneath the coating, lifting the epoxy and causing bubbles or full-scale delamination. As Epoxy.com highlights:

"Coating system bond failures on slabs on grade and elevated/lightweight concrete caused by moisture vapor transmission are the industry’s largest single problem and result in extreme frustration from owners, clients, and contractors."

Appearance and Safety Issues

Neglecting proper surface preparation doesn’t just affect durability – it also impacts safety and aesthetics. Bubbling and blistering create raised areas that can burst, leaving sharp edges or holes. These imperfections trap dirt and bacteria, making the floor harder to clean and unsuitable for spaces like food preparation areas or medical facilities. Additionally, dust or debris trapped under the epoxy creates a gritty, uneven texture, ruining the smooth, glossy finish many expect.

Uneven surfaces and coating failures also pose serious tripping hazards. When epoxy peels or delaminates, the exposed edges can catch on shoes, carts, or equipment, leading to potential workplace injuries and liability concerns.

| Issue | Primary Cause | Visual Symptom |

|---|---|---|

| Peeling/Delamination | Moisture vapor or lack of mechanical profile | Large sheets of epoxy lifting from the substrate |

| Bubbling/Blistering | Outgassing or trapped moisture | Raised domes in the coating surface |

| Fish Eyes | Oil, grease, or silicone contamination | Small, circular craters in the wet film |

| Cracking | Unrepaired substrate cracks or weak laitance | Linear fractures reflecting through the epoxy finish |

| Hot Tire Pick-up | Poor adhesion due to contaminants | Coating sticking to tires and pulling away |

Why Surface Preparation Matters for Epoxy Floors

We’ve already explored what can go wrong when surface preparation is ignored. Now, let’s dive into why getting it right is absolutely critical. Proper surface preparation serves as the backbone of a durable epoxy floor. It’s what determines whether your installation will stand the test of time or crumble under pressure in just a few months. This step is the difference between a floor that lasts for decades and one that costs you time and money in repairs.

When contractors take the time to prepare surfaces correctly, they’re doing more than following a checklist. They’re creating the perfect conditions for strong adhesion. Without this groundwork, even the best epoxy products are doomed to fail.

Restoring the Concrete Surface

During the curing process, concrete develops a thin, fragile layer called laitance. This layer, made up of cement dust and fine particles, forms on the surface as the concrete dries. Unfortunately, if epoxy is applied over this layer, it bonds to the dust instead of the solid concrete beneath, which leads to peeling and failure over time.

Mechanical preparation methods, such as diamond grinding and shot blasting, are essential for removing laitance and other contaminants. These techniques not only strip away the weak surface layer but also create a rough texture – similar to medium-grit sandpaper – that allows the epoxy to grip securely. As GarageFloorCoating.com puts it:

"For coating products to properly bond, the concrete needs to be textured. Simply stated, it needs to be rough because smooth concrete doesn’t provide a receptive substrate."

This roughened surface lets the epoxy penetrate deeply, forming a mechanical interlock that enhances durability. Additionally, mechanical prep removes oils, grease, and old sealers that can act as barriers to adhesion. A quick water drop test can reveal if the surface is clean: if water beads up rather than soaking in, it’s a sign that further degreasing is required.

Once the weak layer is gone, the next step is achieving the right surface profile for optimal adhesion.

Achieving the Right Concrete Surface Profile (CSP)

The Concrete Surface Profile (CSP) is a standardized scale developed by the International Concrete Repair Institute (ICRI), ranging from CSP 1 (nearly smooth) to CSP 9 (extremely rough). For most epoxy applications, a CSP of 3 to 4 is ideal. This level of roughness provides the perfect balance: it’s textured enough for strong bonding without being overly abrasive. On the other hand, surfaces below CSP 2 – often the result of acid etching alone – are typically too smooth to ensure long-term adhesion.

Mike Mincemoyer, President of Stronghold Floors, underscores the importance of this step:

"The foundation for the success of floor coatings depends on whether the concrete has the proper concrete surface profile (CSP) or surface roughness to allow the coatings to properly adhere/bond to it."

The microscopic peaks and valleys created during surface profiling are what give epoxy its ability to anchor firmly to the substrate. When the profile is just right, the epoxy resists shear forces caused by foot traffic, heavy loads, and temperature fluctuations. Combined with proper moisture management – keeping vapor transmission under 3 pounds per 1,000 square feet per 24 hours – this preparation ensures the floor can withstand industrial-grade wear and tear for years without cracking, bubbling, or delaminating.

Methods for Proper Surface Preparation

Essential Surface Preparation Steps for Epoxy Floor Installation

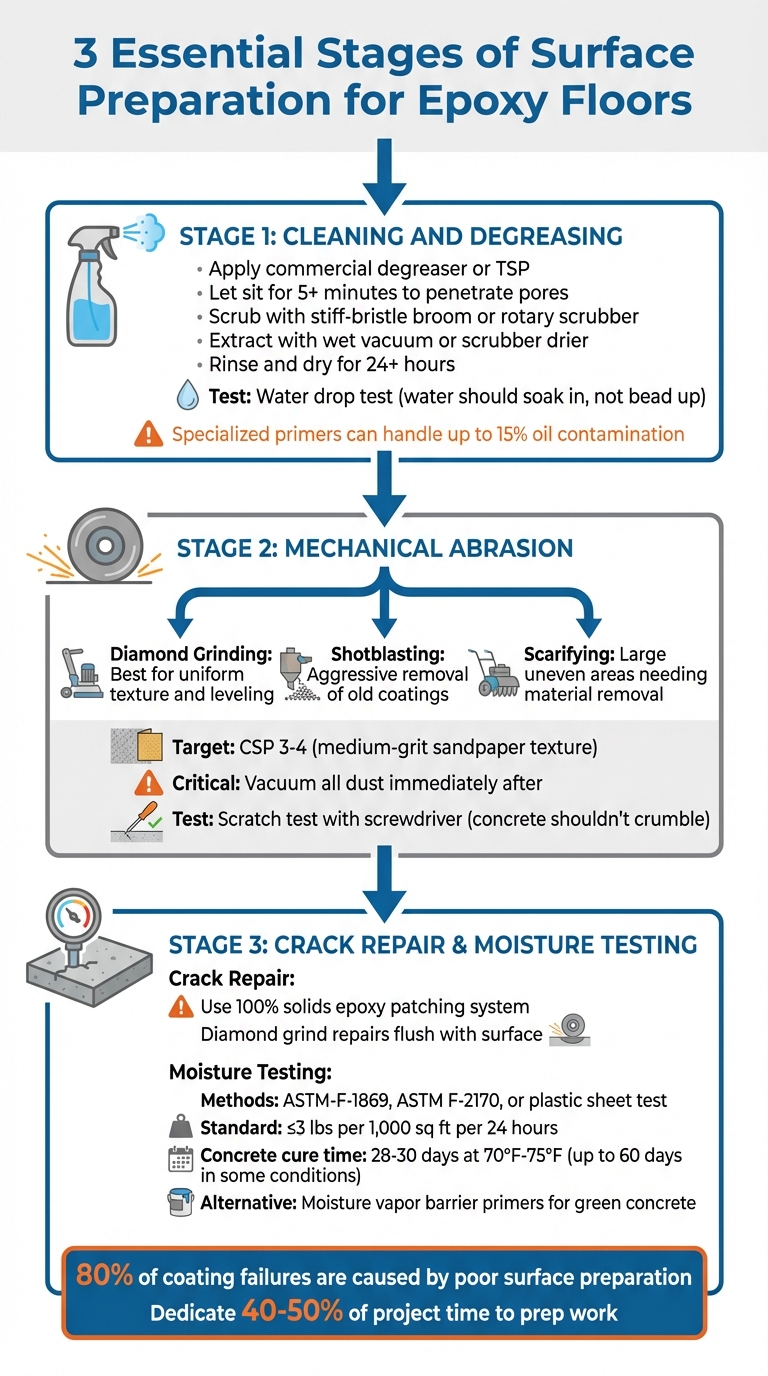

Getting a surface ready for epoxy requires three main stages: cleaning and degreasing, mechanical abrasion, and addressing cracks and moisture. Each step is essential for creating a strong base for the coating.

Cleaning and Degreasing

Before tackling any mechanical work, the concrete needs to be free of contaminants. Substances like motor oil, grease, industrial lubricants, and even food fats can seep into the porous surface of concrete, potentially interfering with the epoxy’s ability to bond properly. A quick wipe-down won’t cut it – any embedded oils can later compromise adhesion.

To tackle this, professionals often use a commercial degreaser or tri-sodium phosphate (TSP), applying it to the affected areas and letting it sit for at least five minutes to penetrate the concrete’s pores. Afterward, the surface is scrubbed thoroughly using a stiff-bristle broom or a rotary power scrubber to lift the contaminants. Extraction is crucial here. Tools like wet vacuums or scrubber driers are ideal for removing the waste liquid, ensuring the oil doesn’t reabsorb. For larger areas, scrubber driers are particularly helpful since they collect the contaminants in a waste tank rather than spreading them around.

Once the surface is rinsed with fresh water, it needs to dry completely – this often takes 24 hours or more – before applying epoxy. A simple water drop test can confirm whether the surface is clean: if water beads up instead of soaking in, it’s a sign that contaminants or sealers are still present. For stubborn oil stains, specialized oil-tolerant primers can help by binding up to 15% oil within their structure, ensuring proper adhesion.

After cleaning, the next step is to roughen the surface mechanically to help the epoxy bond effectively.

Mechanical Abrasion

With the surface clean and dry, mechanical abrasion creates the texture – or "tooth" – needed for the epoxy to adhere securely. Diamond grinding is often considered the best method for both residential and commercial projects, as it opens up the concrete’s pores and provides a consistent bonding surface.

The best method depends on the job’s requirements. Diamond grinding is excellent for achieving a uniform, medium-grit texture and leveling out high spots. Shotblasting is more aggressive and works well for removing thick, old coatings or creating a rougher surface profile. For large, uneven areas that need significant material removal, scarifying is the go-to option. After any of these processes, it’s critical to vacuum up all dust and debris immediately, as even fine particles can weaken the epoxy bond.

A quick test can check the surface’s readiness: scratch it with a screwdriver or tap it with a hammer. If the concrete crumbles or gouges easily, it may not be strong enough to support a durable coating.

Once the surface profile is established, the focus shifts to repairing structural cracks and addressing moisture issues.

Crack Repair and Moisture Testing

Even the best-prepared surface won’t perform well if cracks and moisture problems are ignored. Cracks left unrepaired can show through the finished epoxy, undermining both the look and the durability of the coating. Professionals typically use a 100% solids epoxy patching system to repair cracks. Once patched, the repairs are diamond ground flush with the surrounding surface to ensure a seamless finish.

Moisture testing is just as important. Epoxy acts as a vapor barrier, so trapped moisture can lead to bubbling, peeling, or even delamination. As explained by an expert from Epoxy.com:

"Coating system bond failures on slabs on grade and elevated/lightweight concrete caused by moisture vapor transmission are the industry’s largest single problem".

To detect excess moisture, contractors often rely on methods like ASTM-F-1869 or ASTM F-2170 tests, or even a simple plastic sheet test. Typically, concrete should cure for 28 to 30 days at 70°F–75°F before epoxy application. In some cases, curing may take up to 60 days depending on the environment. If waiting isn’t an option, moisture vapor barrier primers can be applied to freshly poured or "green" concrete to minimize moisture-related issues.

sbb-itb-a0e5ae3

Croc Coatings’ Approach to Surface Prep and Floor Coatings

Croc Coatings takes surface preparation seriously, ensuring every project across North Idaho and Eastern Washington – spanning areas like Spokane and the Tri-Cities – is built to last. Founded by Jim and Kelley Hobart, the company focuses on thorough prep work to avoid the pitfalls that often lead to floor failures. By sticking to these tried-and-true methods, Croc Coatings delivers high-quality, dependable results.

Penntek Evolution Coating System

At the heart of Croc Coatings’ success is the Penntek Evolution system. This polyurea-based coating is a game-changer, offering strength that’s four times greater than traditional epoxy and an impressive 98% elongation, allowing it to flex with the concrete and resist cracking. It’s also UV-stable, meaning it won’t yellow under sunlight – a crucial feature for outdoor spaces like patios, driveways, and garages with large windows. On top of that, the coating can handle stable heat up to 266°F and short-term spikes reaching 430°F. Its antibacterial properties and easy-to-clean surface make it practical for both residential and commercial use.

In January 2026, Croc Coatings showcased this system’s capabilities with two standout projects: a residential garage transformation in Rathdrum, Idaho, and a "Battleship Hybrid" coating installation in Nine Mile Falls, Washington. Both examples highlight how careful preparation and advanced materials come together to create durable, high-performing floors.

This cutting-edge material pairs seamlessly with precise application techniques, ensuring long-lasting results.

Certified Installation Process

Croc Coatings follows a proven, detail-oriented installation process. This includes mechanical abrasion to achieve the ideal concrete surface profile (CSP), epoxy-based crack repairs, and the use of industrial-grade HEPA vacuum systems to manage dust. Technicians also test the concrete slab’s moisture levels using ASTM-F-1869 or ASTM-F-2170 standards to avoid issues like blistering or delamination. For most systems, the acceptable moisture vapor transmission rate is capped at 3 pounds per 1,000 square feet over 24 hours.

Lifetime Warranty and Local Service

To back their work, Croc Coatings provides a lifetime warranty on Penntek residential coatings and a five-year warranty for commercial applications. Their one-day installation process minimizes downtime compared to traditional epoxy, making it a convenient option for clients. As a certified Penntek installer for North Idaho and Eastern Washington, Croc Coatings customizes solutions to handle the region’s challenges, such as salt, dirt, and the extreme temperature swings typical of the Inland Northwest.

Benefits of Proper Surface Prep for Epoxy Floors

Proper surface preparation is the backbone of a durable and visually appealing epoxy floor. By creating a strong mechanical bond, the epoxy securely "keys" into the texture of the concrete, ensuring long-lasting performance – often 10 to 20 years – without the common failures seen in poorly prepared surfaces. Beyond just durability, this preparation enhances the floor’s appearance and makes maintenance far easier.

Professional grinding removes contaminants that could lead to bubbles or uneven surfaces. Additionally, moisture testing helps prevent discoloration, keeping the coating looking clean and polished. This is a critical step in preventing moisture-related coating failures that can ruin the finish. The result? A smooth, glossy finish that not only looks great but also reflects light, brightening up the entire space.

When done correctly, surface preparation also simplifies maintenance. A properly bonded floor resists issues like "hot tire pick-up" and chipping, which are common with DIY installations. This means you’ll spend less time on repairs and more time enjoying your floor. Plus, doing it right from the start eliminates the need for expensive fixes down the road, ensuring the floor performs well for years to come.

To better understand the impact of preparation methods, here’s a comparison between inadequate DIY approaches and expert preparation.

Comparison: Poor vs. Proper Surface Preparation

| Feature | Poor Preparation (DIY/Acid Etch vs. Grinding) | Professional Preparation (Croc Coatings) |

|---|---|---|

| Adhesion Type | Chemical/Surface level only | Deep Mechanical Bond (CSP 2-3+) |

| Longevity | Often fails within months or 1-2 years | Designed to last decades; Lifetime Warranty |

| Finish Quality | Prone to bubbles, peeling, and unevenness | Smooth, uniform, and aesthetically superior |

| Safety | May peel, creating trip hazards | Integrated slip-resistance and structural repair |

| Moisture Resistance | High risk of osmotic blistering | Verified through testing and moisture barriers |

| Durability | Brittle; prone to hot-tire pickup | Flexible (Polyurea); resists chemicals and salt |

Conclusion

The success and durability of your floor hinge on one critical factor: surface preparation. It’s striking to note that around 80% of coating failures stem from poor prep work. Skipping or rushing this step can lead to costly mistakes down the line.

A strong, long-lasting floor demands a solid mechanical bond. This is achieved through proper grinding, thorough moisture testing, and removing contaminants. Experts recommend dedicating 40% to 50% of the total project time to preparation. It’s a necessary investment that ensures your flooring performs as intended.

"Resinous flooring systems are only as sound as the concrete they are applied to." – Epoxy.com

At Croc Coatings, the importance of surface preparation is never underestimated. Their certified team uses industrial-grade tools to create the ideal Concrete Surface Profile, performs comprehensive moisture testing, and addresses any structural concerns before applying Penntek Evolution floor coatings. With a lifetime warranty, this process guarantees durability and peace of mind.

For flooring that stands the test of time, rely on professionals who prioritize preparation. Visit Croc Coatings to discover their one-day installation process and long-lasting results.

FAQs

Why is proper surface preparation essential for epoxy flooring?

Proper surface preparation plays a key role in making sure epoxy coatings stick well and hold up over time. Mechanical abrasion helps eliminate contaminants like curing compounds, sealers, and laitance, while also creating a textured surface that allows the epoxy to bond securely. Skipping this step can result in poor adhesion, which might lead to peeling or a shorter lifespan for the coating.

Taking the time to prepare the surface thoroughly not only boosts the durability and performance of your epoxy floor but also helps it handle heavy use while maintaining its look for years.

What impact does moisture have on the durability of epoxy floors?

Moisture is a major threat to the durability of epoxy floors. When moisture vapor travels through a concrete slab, it builds up pressure beneath the epoxy coating. This can cause problems like bubbling, blisters, cracks, or even delamination, which weakens the bond and shortens the floor’s lifespan.

To avoid these issues, proper surface preparation is key – especially managing moisture levels. Skipping this step can lead to expensive repairs or early failure of the coating.

What are the signs that epoxy flooring wasn’t prepared properly?

Signs of poor surface preparation in epoxy flooring often show up as peeling or flaking, cracks, or discoloration. Other common issues include bubbling, blistering, or delamination – where the epoxy coating lifts away from the surface. You might also notice weak adhesion, which can make the floor feel loose, dusty, or uneven.

Taking the time to properly prepare the surface is key to creating a durable and long-lasting epoxy floor. Cutting corners or rushing through this step can lead to these problems, which not only diminish the floor’s appearance but also its overall performance over time.

Related Blog Posts

- Pre-Installation Checklist: Concrete Floor Coating

- 5 Tips for Preparing Your Space for a 1-Day Floor Coating

- Top Features of Specialty Garage Floor Paints

- How to Clean Concrete for Coating Prep