Why Surface Prep Matters for Concrete Coatings

January 26, 2026

When applying concrete coatings, surface preparation is the most critical step. Without it, coatings are prone to fail, leading to peeling, bubbling, or delamination. Proper preparation removes contaminants, achieves the right surface texture, and addresses moisture and defects, ensuring a strong bond and long-lasting results.

Key Takeaways:

- Contaminant Removal: Oils, grease, and dust must be cleaned off to prevent adhesion issues.

- Surface Texture (CSP): Concrete needs a specific roughness (CSP 1–10) for coatings to grip properly.

- Moisture Control: Testing and managing moisture prevents bubbling and lifting.

- Repairing Defects: Cracks, holes, and weak layers like laitance must be fixed for durability.

Skipping these steps can lead to costly repairs. Companies like Croc Coatings use advanced tools like diamond grinders and shot blasters to ensure proper preparation, delivering durable coatings that last for years.

What Happens When Surface Prep Goes Wrong

Coating Failures from Inadequate Prep

Skipping or rushing through surface preparation almost always results in coating failure. The most common issues – delamination and peeling – happen because the coating can’t properly bond to surfaces that are too smooth or contaminated with curing compounds and release agents.

Another culprit is the laitance layer, which, if left untreated, weakens the bond between the coating and the surface. Jason Ryan, a Materials Specifications Specialist at Cement Colors, explains:

"99% of the bond failure issues I have inspected have either been poor or incomplete surface prep."

Outgassing is another headache. When mechanical profiling opens up the concrete’s pores without adequate priming, trapped air escapes during the curing process. This creates unsightly bubbles and craters in the coating. Residual oils or chemicals on the surface can also interfere with adhesion over time, further compromising the bond.

These bonding problems don’t just affect durability – they also drive up repair and replacement costs.

Expensive Repairs and Replacement Costs

When coatings fail, the financial impact is significant. A failed coating usually has to be completely removed using mechanical methods, which doubles the expense because it requires both repair and reapplication.

With nearly 99% of coating bond failures attributed to poor surface preparation, it’s easy to see how cutting corners becomes a costly mistake. As Polycote succinctly puts it:

"To simply coat over a product that has not fully adhered to the substrate is nothing more than a complete waste of time, effort and money!"

The costs don’t stop there. Failed coatings can lead to ongoing maintenance demands and even pose safety risks, especially in industrial settings.

How to Prep for Floor Coatings | Grinding

Key Steps in Proper Surface Preparation

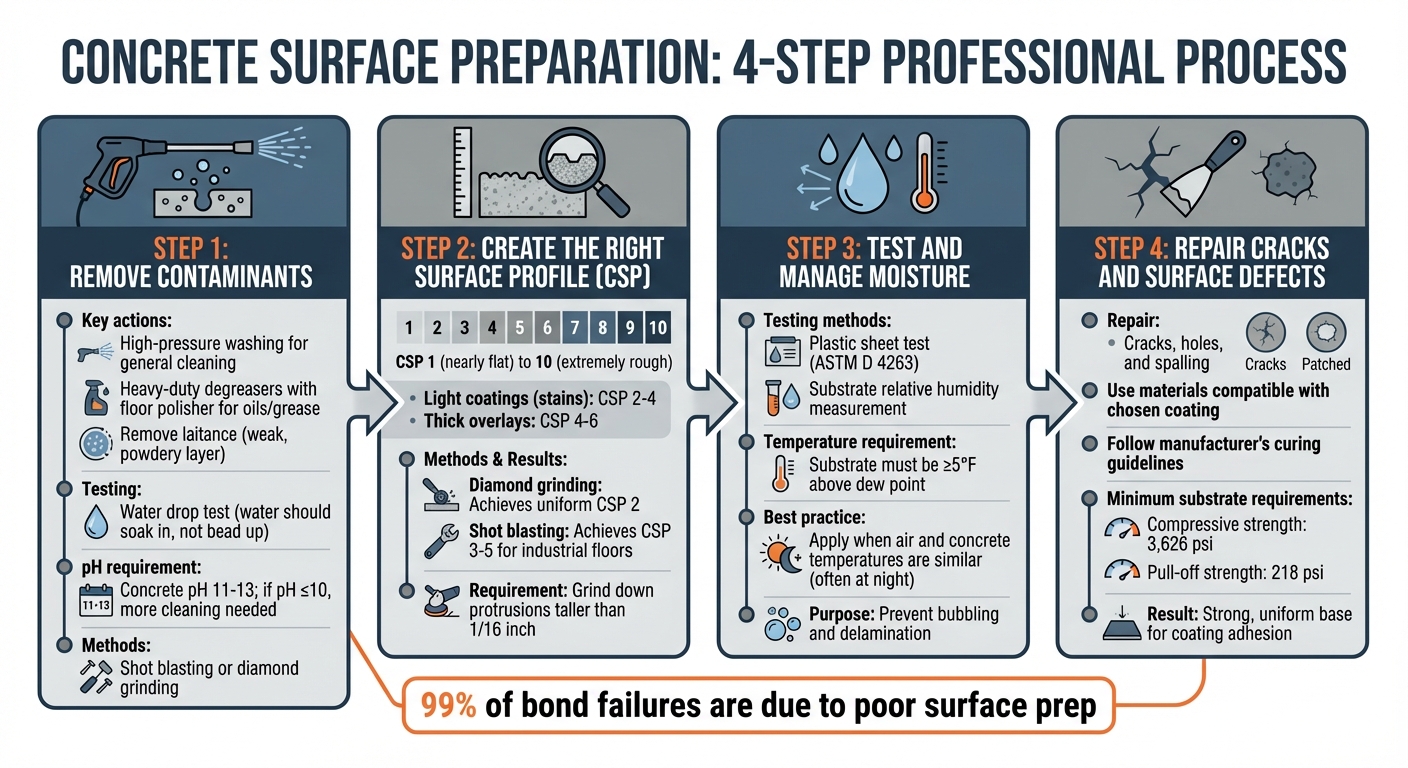

4 Essential Steps for Proper Concrete Surface Preparation

Achieving a durable and long-lasting finish starts with thorough surface preparation. This process ensures the coating adheres properly by addressing all potential issues with the surface.

Removing Contaminants from the Surface

The first step is to remove any contaminants like oil, grease, dirt, or curing compounds. High-pressure washing is effective for general cleaning, while heavy-duty degreasers paired with a floor polisher tackle stubborn oils and greases.

A simple water drop test can help identify hidden contamination. If water beads up on the surface instead of soaking in, further treatment is required. Concrete typically has a pH between 11 and 13. If a cleaned surface tests at a pH of 10 or lower, additional decontamination is needed.

Laitance – a weak, powdery layer of cement and fine sand – must also be removed completely. Mechanical methods such as shot blasting or diamond grinding are highly effective, as they not only remove laitance but also help prepare the surface for better adhesion.

Once the contaminants are gone, the next step is to create the proper surface profile for the coating.

Creating the Right Surface Profile

The surface profile, also known as the Concrete Surface Profile (CSP), is critical for ensuring strong adhesion. The International Concrete Repair Institute categorizes CSP levels from 1 (nearly flat) to 10 (extremely rough). The required profile depends on the type of coating being applied – lighter coatings like stains typically need a CSP between 2 and 4, while thicker overlays call for a CSP between 4 and 6.

Diamond grinding is ideal for achieving a uniform CSP 2, suitable for smooth-to-light finishes. For industrial floors requiring a more textured surface, shot blasting can produce a CSP between 3 and 5. As Victor Pachade of Duraamen explains:

"Surface preparation creates a clean and rough profile that allows epoxy or other coatings to adhere effectively to the concrete substrate. Without it, the coating may not bond properly."

Before applying any coating, make sure to grind down any protrusions taller than 1/16 inch.

Testing and Managing Moisture

Moisture management is essential to avoid issues like bubbling or delamination. Use tests like the plastic sheet test (ASTM D 4263) or measure substrate relative humidity to assess moisture levels. During application, the substrate temperature must stay at least 5°F above the dew point to prevent moisture-related failures.

Timing also matters. Applying coatings when air and concrete temperatures are similar – often at night – reduces the risk of water vapor escaping, which can cause bubbles or craters in non-breathable coatings.

Once moisture is under control, it’s time to address any surface defects.

Repairing Cracks and Surface Defects

Fixing surface defects is a crucial step in creating a strong, uniform base. Cracks, holes, and spalling should be repaired using materials compatible with the chosen coating. Follow the manufacturer’s curing guidelines for these repairs to avoid weak spots that could lead to coating failure.

For a high-performance installation, the substrate should meet minimum strength requirements: a compressive strength of 3,626 psi and a pull-off strength of 218 psi. Properly repaired surfaces ensure the coating adheres evenly and performs as intended.

sbb-itb-a0e5ae3

How Croc Coatings Prepares Surfaces for Long-Lasting Results

At Croc Coatings, surface preparation is the backbone of their promise for durable and long-lasting results. Serving North Idaho and Eastern Washington, the company employs advanced techniques, specialized equipment, and a commitment to quality that supports their lifetime warranty on residential projects.

Industrial-Grade Equipment and Methods

Croc Coatings relies on tools like diamond grinders and shot blasters to create the ideal Concrete Surface Profile (CSP) for each project. For smooth residential garages and commercial floors, diamond grinding achieves a uniform CSP 2. In contrast, shot blasting is used for industrial settings, producing a more aggressive profile – typically between CSP 3 and 5.

To ensure a clean surface, continuous HEPA vacuuming removes fine dust particles that might weaken the bond. This step allows the coating to penetrate the concrete’s pores fully, creating a strong, lasting connection. These methods are the foundation for the tailored preparation process required for Penntek Evolution coatings.

Tailored Prep for Penntek Evolution Coatings

When working with Penntek Evolution coatings – known for being four times stronger than traditional epoxy – Croc Coatings customizes its surface preparation process. The surface profile is adjusted to achieve a CSP of 2 to 4, ensuring optimal adhesion. Unlike acid etching, which can leave chemical residues and bonding issues, mechanical profiling provides a cleaner, more reliable result.

Technicians also address surface imperfections, removing projections over 1/16 inch and repairing cracks with compatible materials to meet the system’s specifications. Before application, moisture testing is performed to confirm that the substrate meets Penntek’s recommended range, ensuring the coating’s long-term performance.

Focus on Safety, Efficiency, and Long-Term Performance

Croc Coatings’ meticulous preparation process prioritizes safety, efficiency, and durability. Using industrial-grade equipment and fast-curing polyaspartic technology, they can complete installations in just one day. The Penntek Evolution coating offers features like UV stability, slip resistance, and antibacterial properties – all of which depend on a properly prepared surface to function as intended.

Founded by Jim and Kelley Hobart, the company is built on professional-grade methods that deliver consistent, measurable results. Whether it’s a garage floor in Spokane or an industrial facility in the Tri-Cities, every project receives the same level of care to ensure a strong mechanical bond and long-term durability, protecting clients’ investments for years to come.

Long-Term Benefits of Proper Surface Preparation

Durability and Performance

Getting the surface preparation right lays the groundwork for a bond that stands up to heavy use, impacts, and exposure to chemicals – without peeling or coming apart over time. The International Concrete Repair Institute has a system for classifying surface textures into ten profiles, ranging from CSP 1 (almost flat) to CSP 10 (extremely rough). This ensures the surface has the right texture to anchor specific types of coatings effectively.

Removing weak layers like laitance is also critical for achieving a durable bond. When done professionally, surface preparation creates a consistent base that can last over 15 years, far outpacing traditional sealers, which often only last 1–3 years. This longevity means fewer replacements, saving money in the long run.

Lower Maintenance and Better Value

Proper surface preparation doesn’t just make coatings last longer – it also makes them easier to maintain. Seamless, non-porous coatings can be cleaned with mild detergents, cutting down on both labor and cleaning product costs. Unlike DIY methods, professional preparation reduces the risk of needing expensive reapplications.

Additionally, high-quality exterior concrete coatings can boost a home’s resale value by 5% to 10%, thanks to improved curb appeal and the impression of care and quality they give to appraisers and buyers. The National Association of REALTORS® even reports that homes with well-maintained exteriors typically sell for 7% more than those with neglected appearances.

Improved Safety and Appearance

Beyond durability and value, proper preparation enhances safety and aesthetics. It removes surface flaws, repairs cracks, and smooths out projections over 1/16 inch, creating a more even and visually appealing finish. Adding slip-resistant materials can further reduce the risk of accidents, especially in high-traffic areas, which helps minimize liability concerns while protecting your investment.

In short, these long-term benefits highlight why careful surface preparation is key to successful concrete coating projects.

Conclusion: Surface Prep is Required for Quality Concrete Coatings

Surface preparation lays the groundwork for long-lasting concrete coatings. Without proper mechanical profiling, contaminant removal, and moisture control, even the best coatings won’t hold up. The difference between a coating that bonds securely to solid concrete and one that merely rests on weak, flaky laitance is the difference between years of durability and the hassle of reapplying.

To ensure this solid foundation, Croc Coatings uses industrial-grade diamond grinding to achieve the precise Concrete Surface Profile required for the Penntek Evolution system. Their process includes moisture testing, repairing defects, and thoroughly removing contaminants, all designed to create a bond that lasts.

Whether it’s a Spokane garage, a Tri-Cities commercial floor, or a North Idaho pool deck, proper surface prep is just as important as the coating itself. Croc Coatings’ certified team follows manufacturer protocols and industry standards like SSPC-SP 13/NACE 6, ensuring every project meets the highest benchmarks. Plus, their residential work comes with a lifetime warranty, reflecting their commitment to getting the prep work right from the start.

If you’re looking for a coating that not only performs and protects but also maintains its appearance for years, surface preparation is non-negotiable.

FAQs

Why is the right Concrete Surface Profile (CSP) important for concrete coatings?

Achieving the right Concrete Surface Profile (CSP) is key to ensuring durable and reliable concrete coatings. The correct level of surface roughness allows coatings to adhere properly, reducing the risk of peeling, cracking, or delamination over time.

Preparing the surface thoroughly – removing contaminants and reaching the ideal CSP – lays the groundwork for a strong bond between the coating and the concrete. This preparation step is critical for durability, helping your concrete surfaces endure the demands of daily use, whether it’s in a garage, on a patio, or within an industrial setting.

Why is moisture control important for concrete coatings?

Controlling moisture is key to maintaining the durability and effectiveness of concrete coatings. When there’s too much moisture, it can weaken the bond between the coating and the concrete surface. This often leads to problems like blistering, peeling, or even delamination. The root cause? Water trapped inside the concrete generates vapor pressure, which disrupts the coating’s adhesion.

To avoid these issues, testing moisture levels before applying any coating is a must. Popular methods include calcium chloride tests or in-situ probes. Additionally, incorporating vapor barriers or moisture-tolerant primers can help manage moisture effectively. Taking these steps during surface preparation ensures the coating lasts longer and performs well, even in challenging conditions.

What happens if you don’t properly prepare the surface before applying concrete coatings?

Proper surface preparation is the backbone of a durable and reliable concrete coating. Skipping this essential step can lead to headaches like peeling, flaking, and weak adhesion, all of which can cause the coating to fail prematurely. Not only does this ruin the surface’s appearance, but it also shortens its overall lifespan.

Taking the time to clean off contaminants, fix any damage, and create the right texture ensures the coating bonds well to the concrete. This process sets the stage for a finish that looks polished and holds up to daily wear and tear.

Related Blog Posts

- Pre-Installation Checklist: Concrete Floor Coating

- Concrete Surface Prep: Inspection Checklist

- Ultimate Guide to Surface Preparation for Concrete Coatings

- How to Clean Concrete for Coating Prep