Why Polyurea Is the Green Choice for Concrete Floors

February 14, 2026

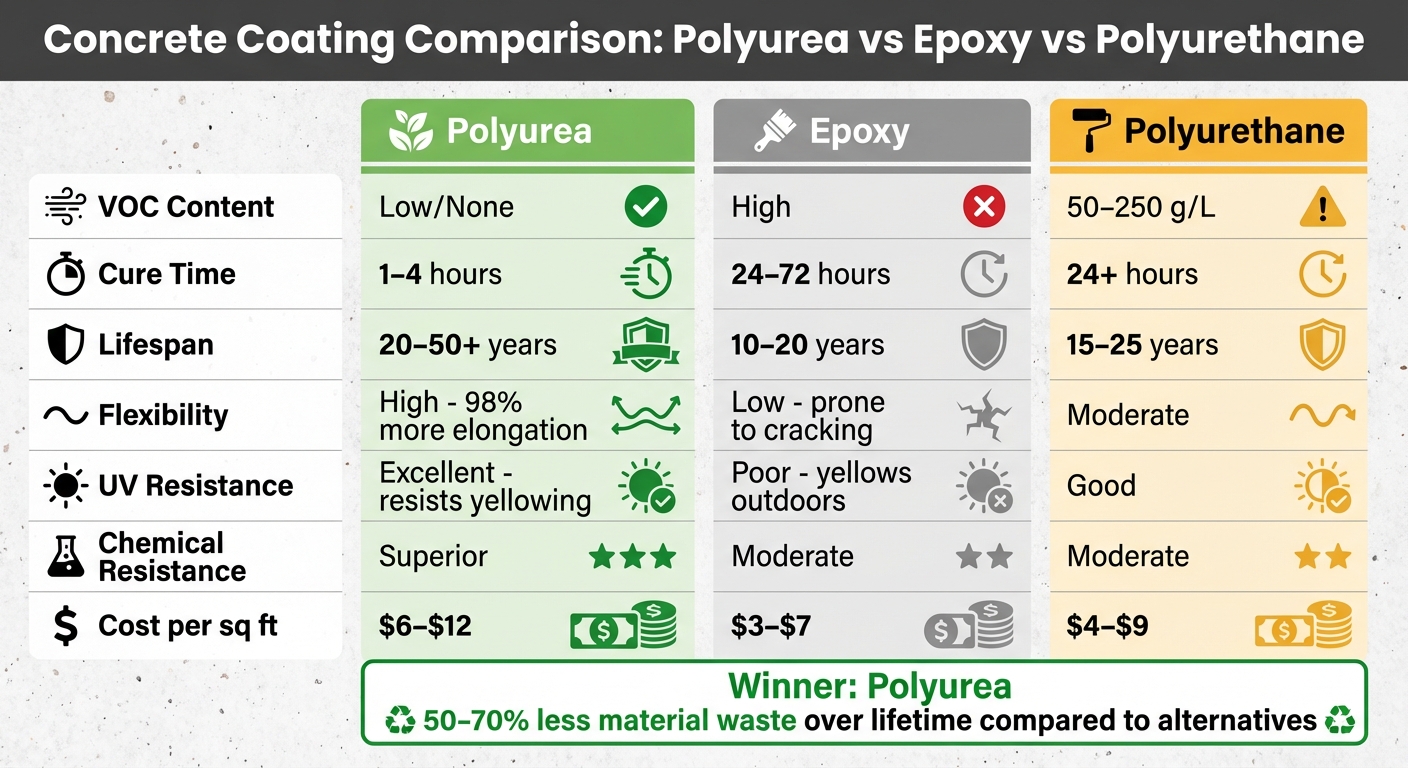

Polyurea is gaining attention as a better option for concrete floor coatings. When comparing polyurea vs. epoxy eco-friendly floor options, polyurea offers key advantages that reduce its impact on health and the environment while delivering long-lasting performance.

Key Points:

- Low Emissions: Polyurea produces almost no VOCs, improving indoor air quality.

- Durable: It lasts 20–50+ years, reducing waste from frequent replacements.

- Fast Application: Cures in 1–4 hours, saving time and energy during installation.

- Chemical Resistance: Protects against spills without contaminating surrounding areas.

- Minimal Waste: Efficient application reduces leftover material.

Quick Comparison:

| Factor | Polyurea | Epoxy | Polyurethane |

|---|---|---|---|

| VOC Content | Low/None | High | 50–250 g/L |

| Cure Time | 1–4 hours | 24–72 hours | 24+ hours |

| Lifespan | 20–50+ years | 10–20 years | 15–25 years |

| Flexibility | High | Low | Moderate |

| UV Resistance | Excellent | Poor | Good |

| Chemical Resistance | Superior | Moderate | Moderate |

| Cost (per sq ft) | $6–$12 | $3–$7 | $4–$9 |

If you’re looking for a coating that lasts longer, improves air quality, and minimizes waste, polyurea is the clear winner. Its higher upfront cost is offset by reduced maintenance and reapplication needs over time.

Polyurea vs Epoxy vs Polyurethane Concrete Coating Comparison Chart

Polyurea vs. Epoxy – This Changed Everything for Garage Floors

sbb-itb-a0e5ae3

1. Polyurea

Polyurea, an elastomer created from isocyanate-resin reactions, is designed as a 100% solids formulation. This unique makeup helps improve indoor air quality in spaces like residential garages and industrial warehouses throughout the United States. Beyond air quality, its composition supports impressive performance features.

VOC Emissions

One standout feature of modern polyurea coatings is their near-zero VOC (volatile organic compound) emissions. This means they don’t release the strong chemical odors often linked to other coatings. Thanks to the 100% solids formula, nearly all of the material remains on the surface instead of evaporating into the air, which is a big plus for maintaining clean indoor air.

Durability and Longevity

Polyurea is built to last. Its flexibility – up to 98% more elongation compared to stiffer coatings – allows it to adapt to concrete’s natural expansion and contraction with temperature changes. Floors treated with polyurea can last 20–30 years or more with little maintenance. Plus, it’s about four times stronger than epoxy, meaning fewer replacements are needed over time. This durability reduces the consumption of raw materials and limits waste.

Cure Time and Energy Efficiency

One of polyurea’s practical benefits is its polyurea curing vs epoxy time. It fully cures in about 24 hours, and floors are ready for foot traffic within hours. This fast turnaround minimizes the time during which any off-gassing might occur and cuts down on energy use for extended ventilation or climate control.

Chemical Resistance

Polyurea is highly resistant to chemicals compared to epoxy. It creates a strong protective layer over the concrete, preventing these substances from seeping through and potentially contaminating soil or groundwater. This makes it especially useful in settings where spills are frequent.

Material Waste

Thanks to its seamless and adaptable application, polyurea works efficiently on various surface types, including complex or irregular shapes. This precision ensures that nearly all of the product is used effectively, resulting in minimal waste. Every gallon of polyurea contributes to the project, making it an efficient and sustainable choice.

2. Epoxy

Epoxy garage floor coatings may offer certain protective benefits, but they come with several environmental and practical concerns. These include issues with indoor air quality, durability, and resource efficiency, making them less appealing in some scenarios.

VOC Emissions

One of the major downsides of epoxy is its high emission of volatile organic compounds (VOCs). These emissions not only degrade indoor air quality but also pose health risks to those exposed to them. On a broader scale, VOCs contribute to atmospheric pollution, adding to environmental concerns.

Durability and Longevity

Epoxy’s rigidity is a double-edged sword. While it provides a hard surface, it can’t handle the natural expansion and contraction of concrete. This lack of flexibility often leads to cracks, especially in areas with significant temperature changes. In extreme climates, epoxy floors may start to fail in as little as 1 to 2 years. Even in milder conditions, their lifespan is generally limited to 5 to 10 years. On top of that, exposure to sunlight can cause yellowing and degradation, further reducing their appeal.

Cure Time and Energy Use

Epoxy coatings require a curing period of 24 to 72 hours, which can be a logistical headache for busy spaces like commercial facilities or residential garages. During this time, extended ventilation is necessary to manage off-gassing, which often demands prolonged use of climate control systems. This not only delays projects but also increases energy consumption, compounding epoxy’s environmental impact.

Material Waste

The relatively short lifespan of epoxy floors means they often need to be replaced every 5 to 10 years. This frequent cycle of reapplication leads to higher raw material usage and more waste, creating a larger environmental footprint over time. These drawbacks highlight the need for alternative solutions, which will be explored further in the next section.

3. Polyurethane

Polyurethane stands out as a middle-ground option when looking at concrete coatings, sitting between epoxy and polyurea. However, it comes with its own set of challenges that affect its environmental impact.

VOC Emissions

One major issue with polyurethane is its release of 50–250 g/L of VOCs, depending on the specific formulation. These emissions can harm indoor air quality and contribute to broader pollution concerns. While low-VOC formulations are available, traditional versions can pose health risks during application and curing, particularly in enclosed areas like garages or basements. This is a stark contrast to polyurea, which has a nearly zero VOC profile, giving it a clear edge in eco-friendliness.

Durability and Longevity

Polyurethane’s durability comes with certain environmental compromises. It typically lasts only 5–10 years in high-traffic areas before requiring reapplication. In comparison, polyurea coatings can last 15–20 years or more, meaning fewer replacements and less raw material usage over time. This longevity is a key reason why polyurea coatings reduce floor maintenance and long-term costs. Additionally, polyurethane lacks the flexibility of polyurea, making it less capable of handling the natural expansion and contraction of concrete surfaces.

Cure Time and Energy Efficiency

The cure time for polyurethane is another drawback. It takes 24–72 hours to cure fully, which prolongs exposure to VOCs and often requires increased energy use for proper ventilation during this period.

Material Waste

Polyurethane applications can also result in 10–20% excess material, leading to more waste. This is especially problematic in complex flooring projects, where the leftover material significantly adds to the environmental footprint.

Advantages and Disadvantages of Each Material

After diving into the specifics of each coating, comparing them side by side highlights the strengths and weaknesses of these materials when used for eco-friendly concrete flooring.

Polyurea stands out as an exceptionally durable option – four times stronger than epoxy and offering 98% more elongation. Its lifespan ranges from 20 to over 50 years, thanks to its flexibility and resistance to UV yellowing. It cures quickly, within 1–4 hours, and emits almost no VOCs, making it a cleaner choice. However, its main downsides are the higher upfront cost, ranging between $6 and $12 per square foot, and the need for professional installation.

Epoxy is a budget-friendly alternative, costing $3 to $7 per square foot. It delivers strong adhesion and a glossy finish. However, it comes with some challenges: high VOC emissions, a longer cure time of 24 to 72 hours, brittleness, and poor UV resistance. These factors limit its lifespan to 10–20 years, making it less ideal for long-term use.

Polyurethane serves as a middle ground. It offers moderate flexibility and good UV resistance, with a lifespan of 15–25 years. However, it emits 50–250 g/L of VOCs, requires over 24 hours for multiple coats to cure, and has lower chemical resistance, which can lead to more frequent maintenance. Its cost falls between $4 and $9 per square foot.

| Factor | Polyurea | Epoxy | Polyurethane |

|---|---|---|---|

| VOC Content | Low/None | High | 50–250 g/L |

| Cure Time | 1–4 hours | 24–72 hours | 24+ hours (multiple coats) |

| Lifespan | 20–50+ years | 10–20 years | 15–25 years |

| Flexibility | High (98% more elongation than epoxy) | Low (prone to cracking) | Moderate |

| UV Resistance | Excellent (resists yellowing) | Poor (yellows outdoors) | Good |

| Chemical Resistance | Superior | Moderate | Moderate |

| Cost (per sq ft) | $6–$12 | $3–$7 | $4–$9 (estimated) |

When it comes to environmentally conscious flooring, polyurea emerges as the top choice. Its extended lifespan, minimal VOC emissions, and resilience mean fewer reapplications, reducing material waste by 50–70% compared to epoxy or polyurethane. Companies like Croc Coatings in North Idaho and Eastern Washington are leveraging polyurea to provide high-performance, eco-friendly concrete flooring solutions that align with sustainability goals.

Conclusion

After examining polyurea, epoxy, and polyurethane, the data makes one thing clear: polyurea stands out as the eco-friendlier option. Here’s why: polyurea is four times more durable than epoxy, delivers 98% greater elongation, cures in just 24 hours, and resists UV rays and chemicals, ensuring it maintains its integrity over time.

Opting for polyurea means choosing durability with a smaller environmental footprint. Its long lifespan reduces the need for frequent recoating, which in turn minimizes the resources spent on production, transportation, and disposal. Companies like Croc Coatings in North Idaho and Eastern Washington highlight this balance of performance and sustainability, offering lifetime warranties on their polyurea installations.

For those prioritizing both sustainability and high performance, polyurea emerges as the top choice for concrete coatings. Its combination of durability and reduced environmental impact makes it the go-to solution for eco-conscious flooring.

FAQs

Is polyurea safe to apply indoors?

Polyurea is safe for indoor use. It releases very low levels of VOCs, which helps keep indoor air quality intact. Plus, its fast curing time means less energy consumption and minimal disruption, making it a smart and efficient choice for indoor projects.

How long will a polyurea floor coating really last?

A polyurea floor coating, when installed by professionals and maintained correctly, can last 15 to 25 years or even longer. Its durability and ability to withstand wear make it a dependable, long-term choice for concrete floors, offering great performance and value over the years.

Does polyurea need special prep or professional installation?

Proper surface preparation is key when working with polyurea. This involves cleaning, repairing, and priming the concrete to create the right foundation for application. To achieve the best results in terms of durability and adhesion, it’s highly recommended to opt for professional installation. Experts bring the necessary tools and skills to handle the process with precision, ensuring a long-lasting finish.

Related Blog Posts

- How Polyurea Coatings Reduce Environmental Impact

- Polyurea vs. Epoxy: Eco-Friendly Garage Floor Options

- Polyurea vs. Epoxy: Eco-Friendly Benefits

- How Polyurea Coatings Support Green Living