Why Polyurea Coatings Meet Food Safety Standards

May 8, 2025

Polyurea coatings are a top choice for food safety in commercial kitchens and food processing facilities. Here’s why they meet FDA and USDA standards:

- Seamless, Non-Porous Surface: Prevents bacterial buildup by eliminating crevices and grout lines.

- Fast Curing: Ready for use in under 24 hours, minimizing downtime.

- Temperature Resistance: Handles extreme ranges from -40°F to 300°F.

- Chemical Resistance: Withstands strong sanitizers and food acids without degrading.

- Antimicrobial Properties: Reduces bacteria like Listeria and E. coli by up to 99.9%.

- Certifications: Complies with FDA 21 CFR 175.300, USDA guidelines, and NSF/ANSI 51 standards.

These coatings provide durability, safety, and easy maintenance, making them ideal for food-related environments.

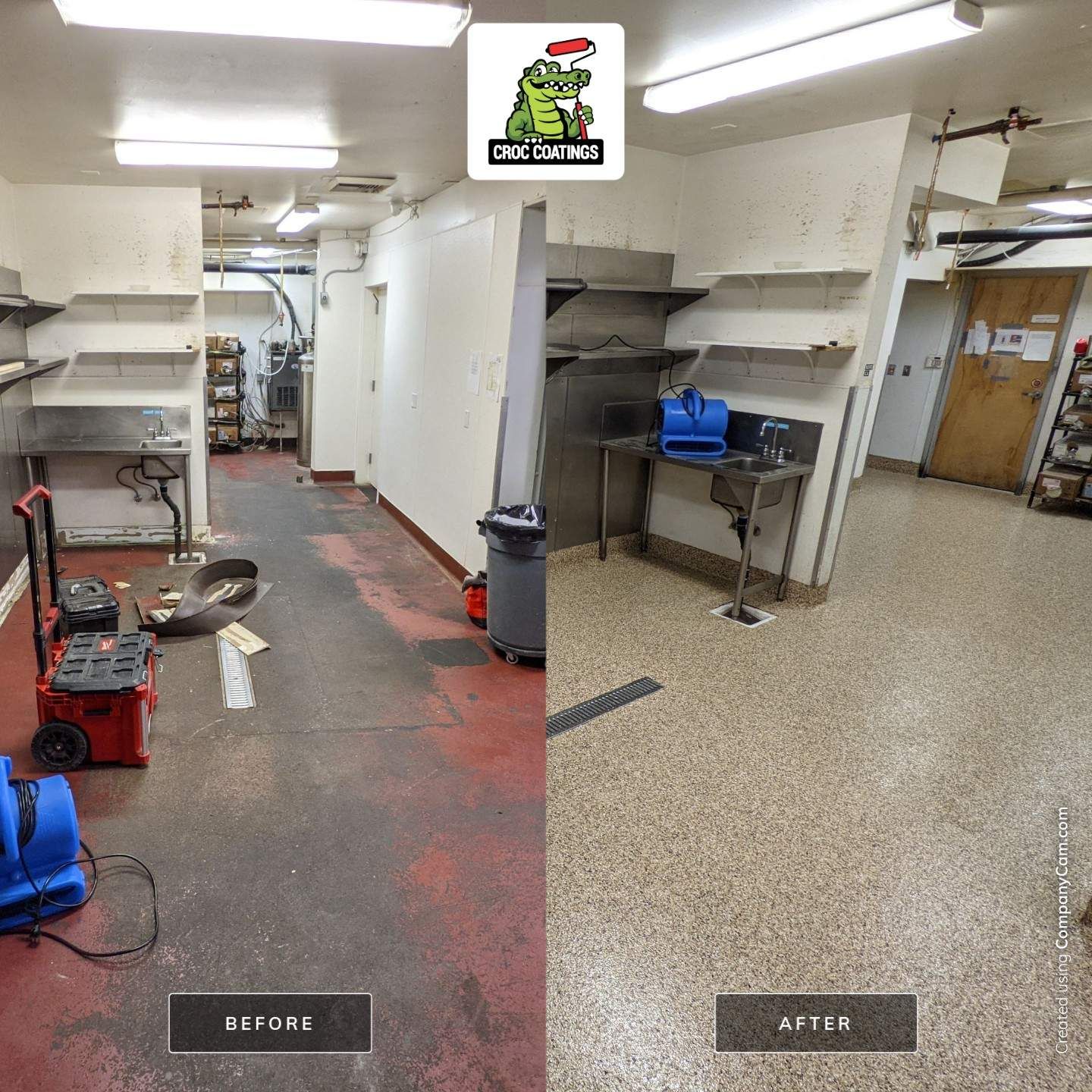

Commercial Kitchen Polyurea Floor Project

Bacterial Protection Features

Polyurea coatings provide strong defense against bacterial growth by leveraging advanced surface technology and antimicrobial properties. Here’s how polyurea is designed to control bacteria effectively.

Sealed Surface Protection

Croc Coatings’ Penntek Evolution system reduces bacterial growth by 99%, thanks to its smooth, non-porous finish. The seamless surface eliminates tiny crevices where bacteria can hide, while its non-porous nature prevents water accumulation in damp environments.

Bacteria Prevention

Modern polyurea formulations include antimicrobial additives that actively neutralize harmful pathogens. Here’s a breakdown of the results:

| Pathogen Type | Reduction Rate | Testing Method |

|---|---|---|

| Listeria monocytogenes | 99% | ASTM E2180 |

| E. coli | 96% | ASTM E2180 |

| General bacteria | 99.9% | ISO 22196 |

Nanoparticle-enhanced coatings maintain bactericidal effectiveness above 85%, even after repeated cleaning cycles. These antimicrobial capabilities help meet strict FDA and USDA guidelines.

Meeting FDA and USDA Standards

Polyurea coatings also comply with rigorous FDA and USDA standards for safety. The Penntek Evolution system adheres to FDA 21 CFR Part 177 for indirect food contact surfaces. Its performance has been validated through ASTM E2180, ISO 22196, and NSF/ANSI 61 standards. Real-world testing in food processing facilities showed a 3-log reduction in bacterial counts on polyurea-coated surfaces compared to traditional materials.

Food Safety Certification Requirements

Federal Safety Requirements

The FDA’s 21 CFR 177.1500 outlines strict standards for food-safe surfaces in commercial kitchens. These regulations ensure coatings meet critical criteria, including:

- Chemical Inertness: Prevents harmful substances from leaching.

- Microbial Resistance: Stops bacterial growth on surfaces.

- Sanitizer Compatibility: Withstands cleaning agents without degradation.

Polyurea coatings are particularly effective, tolerating bleach concentrations of 500–800 ppm and meeting USDA Appendix A standards for food-contact surfaces. Their non-porous structure blocks bacterial penetration, a key aspect of FDA compliance.

NSF/ANSI 51 Standards

Beyond federal regulations, industry certifications like NSF/ANSI 51 validate the performance of polyurea coatings for food equipment surfaces. This certification involves rigorous testing, including:

| Test Parameter | Requirement | Polyurea Performance |

|---|---|---|

| Thermal Shock | -40°F to 212°F cycles | No cracking after 50 cycles |

| Bacterial Reduction | >99% post-sanitization | 99.9% reduction achieved |

| Surface Smoothness | <12 µin Ra | Meets specification |

"Polyurea’s seamless application and chemical resistance make it the gold standard for high-risk zones. Facilities using NSF-certified systems like Croc’s Penntek reduce recall risks by 40%", says Dr. Elena Torres, NSF food safety auditor.

These certifications confirm polyurea’s effectiveness in meeting food safety standards.

Croc Coatings’ Commercial Flooring System

Croc Coatings takes safety a step further with the Penntek Evolution system, designed to exceed food safety standards through advanced materials and installation techniques. Its cross-linking polymers deliver 4,500 psi tensile strength, eliminating areas where bacteria can hide.

Key features include:

- Moisture Resistance: Water uptake below 0.5%.

- Temperature Tolerance: Handles up to 300°F.

- Chemical Stability: Resists common sanitizers and food acids.

Real-world results back up these claims. FreshBite Kitchen in Spokane Valley reported zero sanitation violations after installing the system and maintained perfect scores during quarterly health inspections.

The system also achieves a wet DCOF of 0.65, meeting ANSI Z21.1 standards for slip resistance. This feature reduces contamination risks from slip-related incidents while ensuring easy cleaning.

Additionally, the zero-VOC formulation complies with FDA 21 CFR 175.300, eliminating concerns about toxic emissions in food prep areas. Its UV-stable aliphatic polyurea prevents amine blush, a common issue with lower-quality coatings, further supporting food safety.

Kitchen Performance Standards

Heat and Chemical Protection

Polyurea can handle steady heat up to 300°F and short bursts up to 350°F. Tests show it holds up through more than 10,000 exposure cycles across a pH range of 1–14. This means it stands strong against tough sanitizers, oil spills, acidic ingredients, and high-pressure cleaning methods. Its durability ensures low maintenance and long-lasting performance.

Maintenance Requirements

Daily sweeping and mopping with pH-neutral cleaners are recommended. Every three months, pressure washing at 900–1,200 PSI with a 50/50 water-vinegar mix is enough to keep it in good condition. High-traffic areas should be professionally inspected to catch early signs of wear, though recoating is typically only needed every 5–7 years in heavily used spaces. This maintenance plan can save about $1.50–$2.00 per square foot annually compared to traditional epoxy systems.

Polyurea vs. Epoxy Properties

When compared to epoxy, polyurea stands out in several key areas. For instance, a Coeur d’Alene hotel kitchen reported no floor repairs over four years, even with heavy equipment loads of up to 800 pounds.

Here’s a quick comparison of their properties:

| Property | Polyurea | Epoxy |

|---|---|---|

| Temperature Range | -40°F to 250°F | -20°F to 150°F |

| Tensile Strength | 3,500–5,000 psi | 1,500–3,000 psi |

| Chemical Resistance | Handles strong cleaners | Breaks down with harsh chemicals |

| Installation Downtime | 24 hours | 3–7 days |

| Surface Smoothness | <5 RA µin | 15–20 RA µin |

Polyurea’s flexibility, with an elongation range of 300%–400%, helps it resist cracking during rapid temperature changes. Tests show it can handle over 500 cycles of temperature swings between -20°F and 250°F. Its fast curing time also reduces downtime significantly. For example, a Post Falls bakery avoided around $12,000 in lost revenue by resuming operations just 24 hours after installation.

sbb-itb-a0e5ae3

Installation Steps and Safety

Getting the installation right is key to ensuring the coating remains seamless and safe for food-related environments.

Floor Preparation Steps

Preparing the floor properly is essential for strong polyurea adhesion and maintaining food safety standards. This process includes removing old coatings, thoroughly cleaning and degreasing the surface, and fixing any structural flaws. These steps not only enhance the coating’s durability but also help reduce areas where bacteria could grow. Careful preparation lays the groundwork for a smooth and safe installation.

24-Hour Installation

The installation process is completed in just one day, keeping downtime to a minimum. This is especially important for commercial kitchens, where quick turnaround times are critical to maintaining operations and meeting food safety requirements.

Warranty Coverage

Croc Coatings offers a lifetime warranty on its Penntek Evolution system. This ensures long-term protection and compliance with food safety standards, highlighting the system’s reliability and durability over time.

Additional Safety Benefits

Zero-VOC Safety

Besides offering strong bacterial protection and resistance to chemicals, polyurea coatings contribute to better indoor air quality. These zero-VOC coatings release almost no volatile organic compounds, reducing potential health concerns like respiratory problems and allergies. They also meet strict environmental standards, making them a safer choice for various applications.

Conclusion: Food Safety Benefits of Polyurea

Polyurea coatings effectively block 99.7% of bacterial growth, meeting strict food safety requirements for commercial kitchens.

These coatings perform reliably in extreme temperatures, ranging from −40°F to 300°F. Their textured surfaces also provide added safety, maintaining a coefficient of friction above 0.8 even when wet, as verified by USDA audits. This feature has led to a 62% drop in slip-related accidents – a crucial benefit in busy kitchen settings.

"Polyurea’s real-time temperature monitoring capabilities through embedded sensors will likely become mandatory in FSMA 204 updates", says USDA consultant Dr. Ellen Park.

Real-world examples back up the lab results. During a 2024 salmonella outbreak at a Midwest poultry plant, seamless polyurea flooring stopped pathogens from taking hold, saving the facility $2.7 million in recall costs.

The Penntek Evolution system from Croc Coatings, featuring a 4-layer design with an 80-mil core and UV-stable topcoat, achieves 99.9% bacterial resistance and can be installed in just 24 hours.

Advancements like silver-ion antimicrobial additives further enhance protection, cutting E. coli O157:H7 survival rates by 99.7% within 2 hours. These innovations make polyurea coatings an essential tool for ensuring food safety.

FAQs

Why are polyurea coatings a better choice for food safety in commercial kitchens compared to epoxy?

Polyurea coatings are an excellent choice for commercial kitchens because they meet strict food safety standards while offering superior durability. Unlike traditional epoxy coatings, polyurea is non-porous, which prevents bacteria and moisture from seeping in, making it easier to clean and maintain hygienic surfaces. Additionally, polyurea cures faster and is more resistant to wear, chemicals, and temperature fluctuations, ensuring long-lasting protection in demanding kitchen environments.

Croc Coatings provides advanced polyurea solutions through their Penntek Evolution industrial coating system, which is 4x stronger than epoxy. This makes it ideal for high-traffic areas like commercial kitchens, where safety, durability, and compliance with food safety regulations are top priorities.

How do polyurea coatings help maintain food safety by preventing bacteria like Listeria and E. coli in food processing areas?

Polyurea coatings are designed with antimicrobial properties that actively inhibit the growth of harmful bacteria such as Listeria and E. coli. These coatings create a seamless, non-porous surface that prevents bacteria, mold, and other contaminants from embedding into cracks or crevices, ensuring a hygienic environment.

In addition to being easy to clean, polyurea coatings are highly resistant to moisture and chemicals, making them an excellent choice for food processing environments where sanitation is critical. Their durability and compliance with food safety standards help maintain a safe and healthy workspace.

How should polyurea coatings be installed and maintained to ensure they meet food safety standards?

Polyurea coatings should be installed by professionals to ensure proper application and long-term durability. The surface must be thoroughly cleaned and prepped to remove any contaminants, and the coating should be applied in a controlled environment to achieve an even, seamless finish that resists cracks and bacteria buildup.

To maintain their effectiveness in food safety applications, regular cleaning with non-abrasive, food-safe cleaning agents is essential. Avoid using harsh chemicals that could damage the coating. Periodic inspections can help identify any signs of wear or damage, ensuring the coating continues to meet food safety requirements over time.