Protecting Stone-Look Patios in Harsh Climates

February 10, 2026

Stone-look patios in areas like North Idaho and Eastern Washington face extreme challenges: freezing temperatures, UV damage, heavy rainfall, and de-icing salts. These conditions cause cracking, spalling, fading, and grout erosion, which can ruin both the appearance and durability of your patio.

The Penntek Evolution Coating from Croc Coatings offers a long-term solution. It’s four times stronger than epoxy, resists freeze-thaw damage, blocks UV fading, and includes a slip-resistant finish. Plus, it’s installed in just one day and comes with a lifetime warranty.

Key Features:

- Freeze-Thaw Protection: Prevents cracks and spalling by forming a moisture-blocking layer.

- UV Resistance: Stops fading and discoloration from sunlight.

- Slip Resistance: Safer to walk on in wet or icy conditions.

- Low Maintenance: No need for frequent resealing; simple cleaning keeps it looking great.

By protecting your patio with this industrial-grade coating, you’ll budget for your patio coating to save on repair costs, extend its lifespan, and improve your outdoor space’s appearance – all while reducing maintenance hassle.

Considering a concrete coating? Watch this video first.

sbb-itb-a0e5ae3

Weather Problems That Damage Stone-Look Concrete Patios

In North Idaho and Eastern Washington, outdoor surfaces face a tough mix of freezing temperatures, heavy rainfall, intense sunlight, and corrosive de-icing chemicals. These conditions can wreak havoc on stone-look concrete patios, affecting both their appearance and durability.

Freeze-Thaw Cycles and Cracking

Concrete is porous, which means water can seep into tiny openings. When temperatures drop below 32°F, this trapped water freezes, expanding by about 9%. That expansion puts significant pressure on the concrete’s internal structure. Over time, this leads to cracking, scaling, and crumbling as the freeze-thaw cycles repeat.

The most damage occurs during the shoulder seasons when temperatures frequently rise and fall above freezing. Each freeze-thaw cycle acts like a wedge, slowly prying apart the concrete from within. Sarah Etler from A-1 Concrete Leveling explains it well:

"Freeze-thaw cycles are like an endless tug-of-war between expansion and contraction, stressing concrete until it finally cracks under pressure".

For textured concrete coatings that mimic stone, this process is especially harmful. The top layer often flakes or peels away, exposing the bare concrete underneath and ruining the faux-stone finish.

Snow, Ice, and Slip Hazards

Winter brings its own set of challenges. Snow and ice not only create immediate safety risks but also accelerate long-term damage. During the day, melting snow can seep into the concrete. At night, when temperatures drop, this moisture refreezes, amplifying the freeze-thaw damage. De-icing salts make things worse. While they help melt ice, they also increase the number of freeze-thaw cycles by lowering water’s freezing point. As Concrete Craft describes:

"By melting snow and ice, salt actually creates additional risks of moisture (now in liquid form) seeping into your concrete".

These salts can also corrode steel reinforcements within the concrete and create osmotic pressure that accelerates surface breakdown. The result? A patio riddled with potholes, flaking, and uneven surfaces that become more hazardous with each passing winter.

UV Fading and Discoloration

Sunlight is another enemy of stone-look concrete patios. UV rays break down the chemical bonds in decorative stains and pigments, causing uneven fading and discoloration over time. Fuller Concrete Staining highlights this issue:

"UV rays break down the surface of concrete, leading to uneven fading or patchy discoloration – especially on previously stained or colored concrete".

Prolonged sun exposure also dries out the concrete, stripping it of moisture and natural oils. This can lead to surface chalking, where the top layer turns to powder, or dusting. Combined with the daily effects of thermal expansion and contraction, UV exposure contributes to hairline cracks and surface flaking. Together, these factors undermine both the look and durability of the patio.

In regions with harsh weather conditions, these combined challenges highlight the importance of using weatherproof patio coatings to extend the life of stone-look concrete patios.

Common Damage Signs on Stone-Look Patios

Spotting damage early can save your stone-look concrete patio from further deterioration. Here are some key issues to keep an eye on.

Surface Cracks and Spalling

Hairline cracks may seem minor at first, but they can widen and allow moisture to seep in over time. Once water penetrates the surface, the freeze–thaw cycle in colder months can make things worse, leading to more extensive damage.

Spalling takes this a step further. This happens when chunks of the surface chip, flake, or break away, exposing the coarse aggregate beneath. Spalling can result from corrosion, chemical reactions, or freeze–thaw cycles. Another related issue is scaling, where thin layers of the surface peel off. This often appears as white or light-colored spots, especially noticeable on colored or stone-look patios. If left untreated, scaling can lead to circular depressions that resemble acne scars, ruining the decorative finish.

To check for hidden damage, try the hammer test – lightly tap the surface and listen for a hollow sound, which could indicate underlying deterioration. You can also perform a water absorption test: if water soaks in instead of beading, your patio’s protective sealer might have failed.

Grout Deterioration in Faux Stone Designs

For patios with faux stone designs, grout damage is a common problem. Over time, weather exposure erodes the grout, creating gaps that can attract weeds and pests. You might also notice efflorescence – a white, salty residue – indicating that moisture is moving through the concrete.

As the grout weakens, water can seep into the base layer of the patio. In areas with heavy rain or snow, this can displace the sand foundation, causing stones to shift and become unstable. As Coldspring notes:

"If the water cannot properly drain from a sand set system and gets underneath the stone pavers, the liquid will eventually move the sand and create a rocking scenario, thus compromising the pavers’ durability."

In freezing conditions, trapped moisture can expand, worsening cracks in the grout and threatening the patio’s overall stability.

Stains from Leaves and Mud

Apart from structural issues, stains from environmental debris can hurt your patio’s appearance. Wet leaves, for example, can leave behind brown or black stains on porous concrete. Mud can also clog drainage channels, leading to water pooling that speeds up surface damage.

Chemical exposure is another issue. Pool chemicals, chlorine, and de-icing salts can wear down sealants and cause discoloration. If you notice faded colors or scaling, UV rays or chemical damage may have compromised the protective coating.

To minimize staining, clean organic debris promptly with a pH-neutral soap and rinse off chemical spills right away. If water no longer beads on the surface, it’s time to reseal the patio.

Identifying these signs early can help you take the right steps to protect your patio and keep it looking great for years to come.

Penntek Evolution Coating: Protection for Harsh Climates

If your stone-look patio has seen better days, choosing the right protection system is key – especially in areas prone to freeze-thaw cycles, intense UV exposure, and moisture problems. That’s where Croc Coatings steps in with the Penntek Evolution coating system. This industrial-grade coating is four times stronger than epoxy and specifically designed to handle the extreme conditions of North Idaho and Eastern Washington.

Unlike short-term solutions like sealers, Penntek Evolution creates a tough, seamless barrier that shields against grout deterioration and spalling. Here’s a closer look at how it stands up to the challenges of this demanding environment.

Features of Penntek Evolution Coating

Penntek Evolution is packed with features tailored to withstand the region’s harsh weather conditions:

- UV Stability: This coating defends against sun damage, preventing fading and discoloration during those blazing Eastern Washington summers. Croc Coatings emphasizes its effectiveness:

"UV-resistant concrete coatings like our Croc Floors are an excellent solution to protect outdoor areas from damage and prolong their lifespan."

- Freeze-Thaw Resistance: By forming a moisture-blocking layer, it prevents water from seeping in and causing cracks during temperature swings. The coating is rigorously tested to ensure it flexes with the concrete, staying intact even under shifting conditions.

- Antibacterial Properties: Mold, algae, and mildew don’t stand a chance, even in damp or shaded spots.

- Slip-Resistant Finish: Its textured surface enhances traction, making it safer to walk on in snowy, icy, or wet weather.

One-Day Installation and Lifetime Warranty

Beyond its weather-ready performance, Penntek Evolution also delivers on convenience and peace of mind. Croc Coatings completes the installation in just one day, so your patio gets immediate protection without a lengthy wait.

The system is backed by a lifetime warranty, which covers peeling, fading, cracking, and staining under normal use. This warranty highlights the coating’s long-lasting durability and ensures your investment is protected. Croc Coatings is the exclusive certified installer of Penntek Coatings in the North Idaho and Eastern Washington region, serving areas like Coeur d’Alene, Spokane, and Tri-Cities.

How to Protect Patios with Penntek Evolution

Getting your patio ready to handle tough weather conditions starts with the right application process. Croc Coatings uses a three-phase method that ensures quick installation with minimal disruption.

Surface Preparation and Repairs

Before applying any coating, the concrete surface must be in excellent condition. Croc Coatings begins by power washing the patio to remove dirt, debris, and any leftover sealers. Afterward, certified installers carefully inspect the surface for cracks or damage, making necessary repairs to create a stable foundation. This step is critical – it eliminates weak points that could compromise the coating’s bond or allow moisture to seep in, especially during freeze-thaw cycles. Once the surface is clean and repaired, it’s ready for the next phase.

Application of Penntek Evolution Coating

With the surface prepped, the Penntek Evolution coating is applied. This self-leveling product is evenly spread across the patio, creating a durable, stone-look finish. Certified installers ensure the coating includes built-in slip resistance, which is especially helpful in snowy or icy conditions. The coating undergoes rigorous testing to guarantee flexibility and resistance to stains. As Croc Coatings highlights:

"Professionally installed concrete coatings in just one day with a Lifetime Warranty!"

A simple maintenance routine is all it takes to keep the coating performing well for years to come.

Post-Application Maintenance Tips

After installation, maintaining your patio is straightforward. Remove snow promptly to prevent moisture buildup, which can strain even a well-protected surface. Use mild cleaners for routine cleaning and avoid harsh chemicals that might damage the coating. Croc Coatings emphasizes the ease of upkeep:

"Croc Floors require minimal maintenance, making them a popular choice for outdoor areas. They are easy to clean and do not require frequent sealing or reapplication like most sealers."

Unlike traditional sealers that need regular reapplication, Penntek Evolution offers a one-time solution, backed by a lifetime warranty.

Long-Term Benefits of Protecting Stone-Look Patios

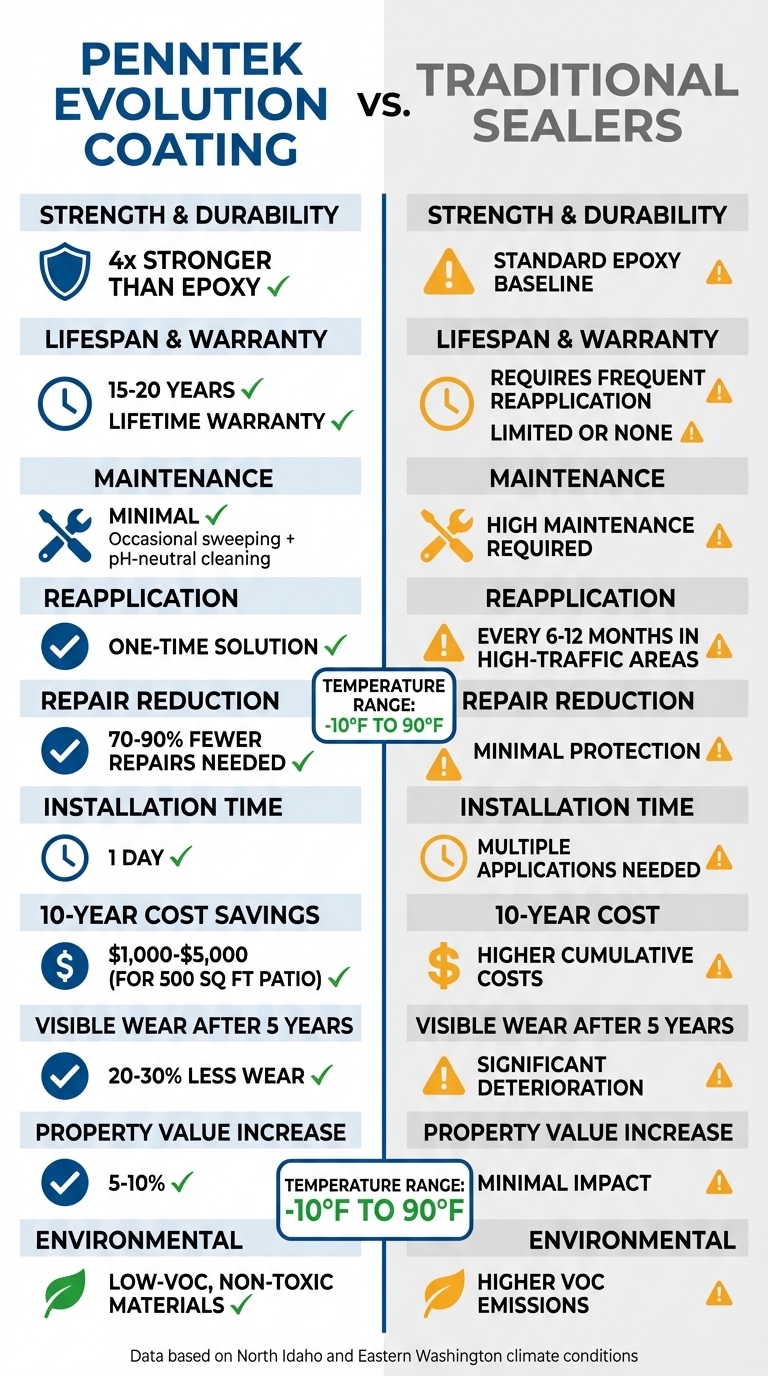

Penntek Evolution Coating vs Traditional Sealers: Durability and Cost Comparison

Over time, Penntek Evolution coating does more than just shield patios from immediate weather damage – it provides lasting advantages that make it a smart investment.

Better Durability in Harsh Climates

Penntek Evolution coating offers strength that’s four times greater than standard epoxy. This toughness creates a moisture-resistant barrier, which is crucial during freeze-thaw cycles, as it helps prevent cracking and spalling. It also resists UV fading and surface wear caused by intense sunlight, ensuring the patio maintains its integrity for years.

By blocking issues like efflorescence and erosion, coated patios can cut down repair needs by 70–90%. These surfaces can last 15–20 years, even in climates with temperatures ranging from -10°F to 90°F. Unlike traditional sealants that often require reapplication every 6–12 months in busy areas, Penntek Evolution comes with a lifetime warranty, reducing the hassle and cost of frequent repairs.

This durability not only extends the life of your patio but also keeps it looking great over time.

Better Appearance and Property Value

The faux stone finish of a patio coated with Penntek Evolution stays vibrant, as the coating guards against UV discoloration, stains, and weathering. Grout lines remain intact, and the patio retains its like-new appearance throughout the year. This enhanced curb appeal isn’t just for show – it can boost property values by 5–10% in areas like Spokane. In regions like North Idaho, coated patios show 20–30% less visible wear after five years, which often leads to faster home sales and higher appraisals.

So, while the coating reduces maintenance costs, it also adds measurable value to your home.

Eco-Friendly and Low-Maintenance Solution

Penntek Evolution is designed with low-VOC, non-toxic materials, which means fewer harmful emissions during application. It also resists chemical de-icers, reducing runoff pollution compared to traditional sealants. Its long-lasting performance minimizes the need for replacements, saving resources in the process. Maintenance is simple – just occasional sweeping and pH-neutral cleaning, with no need for annual resealing or major crack repairs. For a 500-square-foot patio, this can translate into savings of $1,000 to $5,000 over 10 years.

As Croc Coatings puts it:

"Croc concrete coatings are a cost-effective solution for outdoor areas. They are less expensive than replacing concrete surfaces and require less maintenance than other coatings."

Conclusion

Stone-look patios in North Idaho and Eastern Washington endure harsh conditions, including freeze-thaw cycles, intense UV rays, and persistent moisture. These factors wear down grout lines over time, causing patios to degrade and leading to expensive repairs or even full replacements.

The Penntek Evolution system from Croc Coatings offers a powerful defense against these challenges. This coating is four times stronger than epoxy, providing superior resistance to moisture and UV damage. Plus, with a one-day installation and a lifetime warranty, homeowners can enjoy fast, reliable protection.

This durable solution also means less upkeep. Patios coated with the system require only basic cleaning and occasional sweeping to maintain their appearance.

As Jim Hobart, the owner of Croc Coatings, puts it:

"Epoxy floors just don’t stand up to the freeze/thaw cycles we encounter here in the Northwest".

Designed specifically for the demanding climates of North Idaho and Eastern Washington, the Penntek Evolution system ensures your patio stays protected for years to come. It’s the ultimate choice for maintaining the beauty and durability of your outdoor space, no matter the weather.

FAQs

Can Penntek Evolution be applied over my existing sealer or stain?

Yes, Penntek Evolution coatings can be applied over existing sealers or stains, but proper surface preparation is key. This involves thoroughly cleaning the area and checking for compatibility to ensure strong adhesion and durable protection.

How soon can I walk on or use the patio after installation?

You can typically start using the patio just 24 hours after the coating is applied. The fast-curing process ensures the surface is ready for foot traffic or general use within that short timeframe.

What de-icers and cleaners are safe on a coated patio?

When it comes to safer de-icing options, consider using organic compounds like urea or sugar beet. Another good choice is magnesium chloride, which is gentler on concrete and plants and remains effective in temperatures as low as -13°F.

It’s best to steer clear of salt-based de-icers such as rock salt or calcium chloride, especially if you’re dealing with new or unsealed surfaces, as these can cause damage over time.

Related Blog Posts

- Concrete Coatings for Harsh Climates

- Weatherproof Patio Coatings for Harsh Climates

- Custom Patio Coatings for Unique Outdoor Spaces

- How UV Rays Damage Concrete Without Proper Coatings