Moisture Control for Concrete Coatings: Guide

February 13, 2026

Concrete coatings often fail because of hidden moisture within the slab. Even if the surface looks dry, moisture vapor can rise through concrete pores, leading to peeling, blistering, or delamination. Proper moisture control is essential to avoid costly repairs and ensure long-lasting results. Here’s what you need to know:

- Moisture Sources: Groundwater, ambient humidity, and residual water from the concrete mix.

- Testing Methods: ASTM-standardized tests like the Relative Humidity (RH) test (most reliable), Calcium Chloride test, and Plastic Sheet test help measure moisture levels.

- Preparation Steps: Clean the surface, repair cracks, and ensure proper profiling for better adhesion.

- Moisture Barriers: Use vapor barriers or moisture-mitigating primers for slabs with high moisture levels.

- Timing: Allow concrete to dry fully (up to a year in some cases) and stabilize the environment before coating.

The Penntek Evolution system by Croc Coatings offers a durable solution against moisture-related coating failures. Its polyurea basecoat bonds deeply with concrete, while the UV-stable topcoat resists water and chemical damage. With one-day installation and a lifetime warranty, it’s ideal for residential and commercial spaces prone to moisture issues.

How to Handle High Moisture Levels in Concrete Slabs

sbb-itb-a0e5ae3

Why Moisture Control Is Critical for Concrete Coatings

Water vapor can wreak havoc on concrete coatings. When vapor moves through the concrete and encounters an impermeable coating like epoxy, it creates pressure at the bond line, eventually pushing the coating away from the surface. These failures lead to repair costs that add up to billions every year. This pressure, driven by diffusion dynamics, is often the root cause of concrete coating failures.

When a non-breathable coating traps migrating moisture, it can result in blistering, delamination, and adhesive failure. Robert R. Cain, President of Key Resin Company, explains this issue:

"It is the flow of moisture or moisture vapor, better described as moisture vapor transmission, that causes most adhesion problems".

Most concrete slabs are laid over ground with 100% relative humidity. Even high-performance membrane sealers, which can only handle 3 to 5 lbs/1,000 ft²/24 hrs, are vulnerable to bubbling, pinholing, chipping, or efflorescence under these conditions. Beyond structural damage, trapped moisture creates a breeding ground for mold, mildew, algae, and bacteria beneath flooring systems, contributing to Sick Building Syndrome. Moisture can also spread into adjacent walls and moldings, leading to rot and further damage.

The cost of repairing a failed coating is three to four times higher than addressing moisture issues upfront. Ethan Knobloch, Owner of Select Coatings, emphasizes the importance of this step:

"Moisture mitigation is almost always necessary before coating concrete. It’s not just a safety step; it’s a performance guarantee".

Skipping this essential process doesn’t save money – it guarantees costly repairs later. Choosing systems like Croc Coatings’ Penntek Evolution, designed to tackle these challenges, is crucial for long-term success.

How Moisture Behaves in Concrete

Concrete is riddled with tiny channels called capillaries, which form as the material cures. These capillaries emerge when water evaporates during the setting process, creating microscopic pathways throughout the slab. These pathways allow both liquid water and water vapor to move freely within the concrete. This constant moisture movement plays a key role in many damage processes.

Moisture in concrete is always on the move. It travels from areas of high concentration to areas of lower concentration in an effort to balance out moisture levels. The ground beneath most concrete slabs holds a relative humidity of 100%, providing a steady source of moisture that pushes vapor upward through the capillaries. This movement intensifies in enclosed, air-conditioned spaces, as cooler surfaces create a "vapor drive" that pulls moisture upward. Robert R. Cain, President of Key Resin Company, explains this phenomenon:

"The attraction or flow of moisture to the surface is the normal flow from a point of higher vapor pressure to a point of lower vapor pressure to create equilibrium".

How Moisture Damages Coatings

When moisture travels to the surface and encounters a non-breathable coating like epoxy, it gets trapped at the bond line. This trapped moisture can cause several types of damage. Dissolved salts and alkalis carried to the surface can produce efflorescence, a white, powdery residue. High pH levels at the surface can chemically degrade adhesives, and osmotic blisters – pockets of water trapped beneath the coating – can form.

In addition to structural issues, moisture can cause visible problems. Excess moisture may lead to sealers turning white or "blushing." Decorative stains, especially those containing copper salts, might darken or turn black. Beyond aesthetics, trapped moisture can foster mold, bacteria, and algae, which can lead to microbiologically induced deterioration. This type of damage weakens the concrete, causing cracks and surface erosion.

Where Concrete Moisture Comes From

To understand how moisture damages coatings, it’s important to pinpoint its sources. Moisture in concrete primarily comes from three places.

- Residual batch water: This is water from the concrete mix itself. It must evaporate before a coating is applied, which typically takes about 90 days for a slab with a 0.50 water-cement ratio. However, under certain conditions, this process can take over a year.

- Groundwater and damp soil: Moisture from below the slab moves upward through capillary action or hydrostatic pressure, especially if no vapor barrier was installed.

- Ambient humidity: Concrete can absorb moisture from the air due to its hygroscopic nature. Additionally, condensation can form on the surface when the slab’s temperature falls below the dew point.

| Moisture Source | How It Moves | Impact on Coatings |

|---|---|---|

| Batch Water | Evaporation through capillaries | Delamination if coated too early |

| Groundwater | Capillary wicking/Hydrostatic pressure | Continuous vapor drive, bond failure |

| Ambient Air | Absorption/Condensation (Dew Point) | Surface blushing, poor adhesion |

| Damp Sub-slab Soil | Diffusion/Vapor transmission | Efflorescence, high pH, osmotic blistering |

How to Test Concrete for Moisture

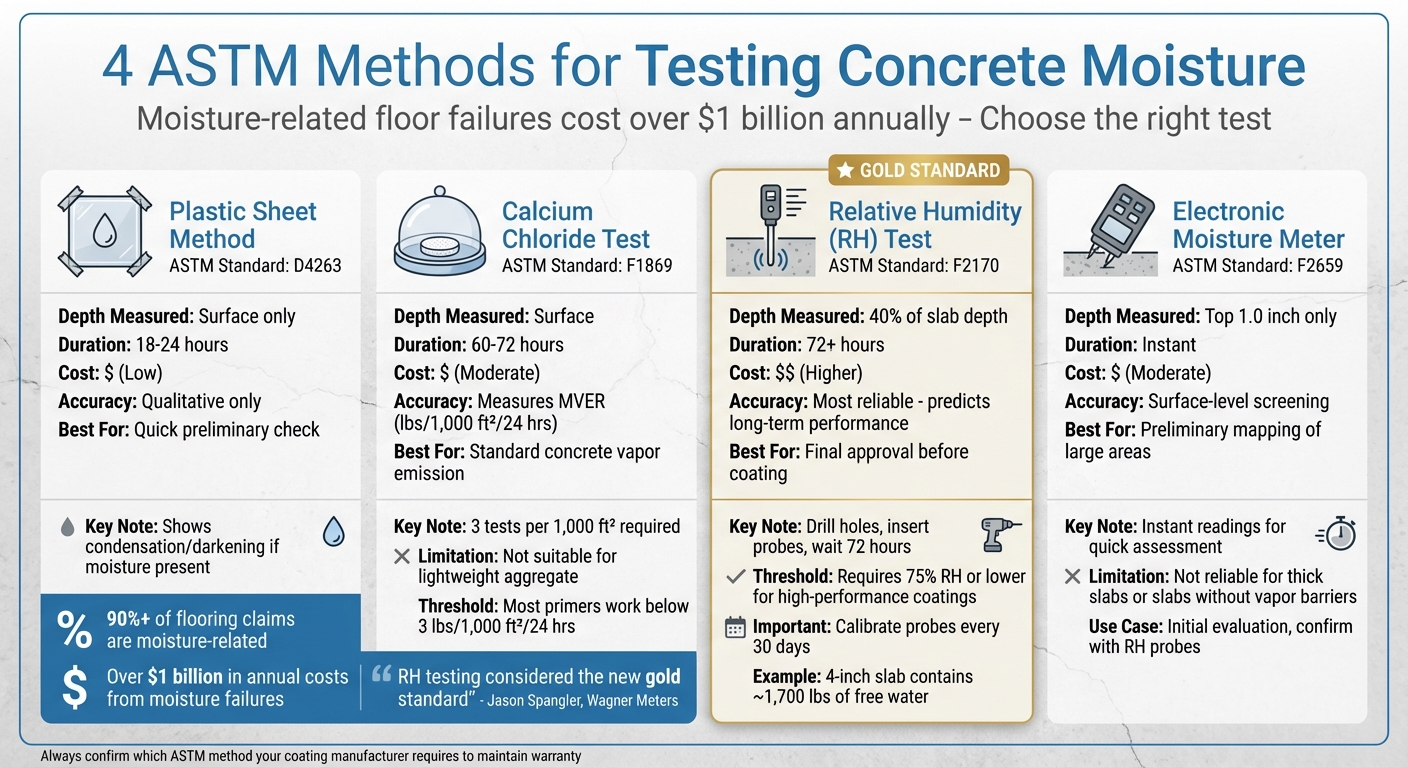

Concrete Moisture Testing Methods Comparison Chart

Before applying any coating, it’s crucial to check the moisture levels in your concrete. The testing method you choose should align with your budget, timeline, and the coating manufacturer’s guidelines. Industry professionals commonly use four ASTM-standardized methods, each with its own benefits and limitations.

Here’s why this matters: Moisture-related floor failures account for over 90% of flooring claims, costing over $1 billion annually. Jason Spangler, Rapid RH Product Sales Manager at Wagner Meters, highlights the importance of accurate testing:

"RH testing is considered to be the new gold standard for concrete moisture testing".

To get reliable results, make sure the HVAC system runs for at least 48 hours before testing. This stabilizes the temperature and humidity, ensuring the readings reflect actual conditions rather than temporary fluctuations.

Now, let’s dive into the four ASTM methods for measuring moisture levels in concrete.

Plastic Sheet Method (ASTM D4263)

This simple, qualitative test checks for surface moisture. Tape an 18×18 or 24×24-inch plastic sheet to the concrete, leaving it in place for 18–24 hours. If you notice condensation or darkening underneath, moisture is present. While this test won’t give you a numerical value, it’s a quick and low-cost way to identify potential issues. If water beads form under the sheet, the concrete is too wet for moisture-sensitive coatings.

Calcium Chloride Test (ASTM F1869)

This method measures the Moisture Vapor Emission Rate (MVER) – how much water vapor escapes from 1,000 square feet of concrete in a 24-hour period. Place a dish of anhydrous calcium chloride under a sealed plastic dome for 60–72 hours. The weight gain of the salt indicates the vapor emission rate. According to ASTM F1869-16a:

"the moisture vapor emission rate only reflects the condition of the concrete floor at the time of the test".

For every 1,000 square feet of concrete, you’ll need three test sites, with one additional site for each extra 1,000 square feet. Most primers work with emissions below 3 lbs/1,000 ft²/24 hrs, though some specialty primers can handle up to 20 lbs. Keep in mind, this test isn’t suitable for lightweight aggregate concrete, as it can give falsely low readings. Also, ensure the surface is clean and free of debris or curing compounds for accurate results.

Relative Humidity Test (ASTM F2170)

The RH test is the most reliable way to predict how a coating will perform over time. Start by drilling holes to 40% of the slab’s depth, inserting in-situ probes, and letting them stabilize for at least 72 hours. For example, a typical 4-inch thick, 1,000-square-foot slab contains about 1,700 pounds of "free water" that needs to evaporate before coating. The RH test measures how much moisture remains inside the slab. High-performance coatings generally require readings of 75% RH or lower, which translates to about 5% moisture content by weight. To maintain accuracy, calibrate reusable probes at least once every 30 days. While this method is more time-consuming and expensive, it provides the most dependable data to avoid common coating defects like delamination or blistering.

Non-Destructive Moisture Meter (ASTM F2659)

Handheld electronic meters offer instant moisture readings within the top 1.0 inch of the slab. These devices use electrical signals to quickly identify high-moisture areas, making them great for mapping large surfaces. However, ASTM F2659-22 notes:

"results from this guide do not provide vital information when evaluating thick slabs, slabs without effective vapor retarders directly under the slab, lightweight aggregate concrete floors, and slabs with curing compound or sealers on the surface".

Use these meters for initial evaluations, then follow up with RH probes to confirm findings in suspicious areas.

| Method | ASTM Standard | Depth Measured | Duration | Best Use Case |

|---|---|---|---|---|

| Plastic Sheet | D4263 | Surface | 18–24 Hours | Quick, low-cost qualitative check |

| Calcium Chloride | F1869 | Surface | 60–72 Hours | Measuring vapor emission rate on standard concrete |

| Relative Humidity | F2170 | 40% of Slab Depth | 24–72 Hours | Internal moisture assessment and final approval |

| Electronic Meter | F2659 | Top 1.0 Inch | Instant | Preliminary mapping and residential diagnostics |

Always confirm which ASTM method your coating manufacturer requires to maintain your warranty. Different coatings have varying moisture tolerances, such as polyurea in humid environments, and using the wrong test could void your warranty, even if the coating initially seems fine. By following these methods, you’ll get accurate moisture readings and set the stage for proper preparation, which we’ll cover next.

How to Control Moisture Before Coating

Once you’ve determined accurate moisture levels, the next step is managing moisture to ensure your coating lasts. Did you know that nearly 80% of concrete coatings fail due to improper surface preparation? The good news is that most moisture-related issues can be avoided with proper prep, effective barriers, and the right timing.

Surface Preparation and Sealers

Preventing bond failures starts with a clean surface. Oil, grease, and chemical residues can block coatings from adhering properly. Use a degreaser and a stiff brush to scrub the surface. A quick test? Pour water on the concrete – if it beads up, the surface is still contaminated and needs more cleaning.

Next, repair cracks or holes using low-shrinkage bonding materials or high-bonding polymers. This step prevents moisture from sneaking through gaps and weakening the coating.

Surface texture matters too. Smooth concrete won’t hold coatings well, so it may need profiling. If the surface feels too smooth to the touch, try acid etching with muriatic acid or use mechanical blast cleaning to open up the pores. For uneven slabs, applying a self-leveling compound can help eliminate low spots where moisture might collect.

Finally, check internal moisture levels using an ASTM F2170 RH test. Surface-level tests only measure the top inch of concrete and can be skewed by ambient humidity.

Vapor Barriers and Epoxy Primers

Once the surface is ready, the next step is blocking moisture from interfering with the coating. For new construction, a Class 1 vapor barrier (thicker than 6-mil puncture-resistant poly) should be placed directly under the slab. This keeps ground moisture – often at 100% relative humidity – from entering the concrete. Positioning the barrier directly beneath the slab (instead of under granular fill) also speeds up the drying process.

For existing slabs with high moisture levels, moisture-mitigating epoxy primers are critical. These primers are designed for slabs with RH levels between 75% and 90% or MVER above 3 lbs/1,000 ft²/24 hrs. Standard primers won’t hold up against high vapor pressures. Some primers, like WearCOAT 1080, can handle vapor pressures as high as 16 lbs. These specialized primers create a chemical bond with the concrete, resisting moisture and preventing delamination of the final coating.

Timing and Environmental Factors

Patience is key when it comes to drying. Concrete can take anywhere from six weeks to over a year to dry sufficiently for non-breathable coatings. Rushing this process often leads to issues like blistering, peeling, or de-bonding.

Environmental conditions also play a huge role. HVAC systems and ambient conditions affect how moisture moves through the slab. For accurate moisture testing and proper bonding, make sure the HVAC system is running under normal operating conditions well before testing or coating.

If you’re on a tight schedule, tools like heat and dehumidifiers can help speed up drying. Protect the slab from rain and avoid cleaning methods that introduce extra moisture. Manufacturers typically recommend aiming for an RH of 75% to 80% and an MVER of no more than 3 lbs/1,000 ft²/24 hrs before applying a coating. In extremely wet conditions, MVER values can exceed 10 lbs/1,000 ft²/24 hrs – far too high for most coatings.

| Factor | Impact on Moisture Control |

|---|---|

| Ambient Temperature | Cooler air relative to the slab increases moisture migration to the surface |

| Relative Humidity (RH) | High RH slows slab evaporation; low RH speeds it up |

| HVAC Operation | Stabilizes the environment, crucial for accurate testing and coating success |

| Curing Method | Curing under plastic for 3 days is ideal; moist curing beyond 7 days extends drying time |

Croc Coatings‘ Penntek Evolution System and Moisture Resistance

Penntek Evolution System Features

Croc Coatings tackles moisture challenges head-on with its Penntek Evolution system, a solution specifically designed to address issues that can compromise traditional coatings.

At the heart of this system is a 99% pure, filler-free polyurea basecoat that forms a chemical bond deep within concrete pores. This bond significantly reduces the risks of delamination and blistering, which are common problems with conventional coatings. Unlike epoxy, which can crack under stress compared to polyaspartic, polyurea adapts to temperature shifts and concrete movement – making it a reliable choice for outdoor surfaces that endure freeze-thaw cycles.

According to Keystone Concrete Coatings, "At the core is a 99% pure polyurea basecoat that chemically bonds to the pores in the concrete, offering unmatched flexibility, adhesion, and long-term durability."

The system also features a polyaspartic topcoat that’s UV-stable and resistant to water penetration, fading, and chemical damage. This topcoat prevents mold growth, making it a smart pick for basements. For wet areas like pool decks, the multi-layer flake system adds a slip-resistant texture while maintaining durability.

Applications for Homes and Businesses

The Penntek system is versatile, performing exceptionally well in moisture-prone areas for both residential and commercial use.

In homes, it protects:

- Garage floors from hot tire pickup.

- Patios and driveways from rain, snow, and freeze-thaw cycles.

- Pool decks from constant water exposure.

- Basements from ground moisture and mold.

Its slip-resistant finish also enhances safety in wet environments, making it a practical choice for families.

For businesses, the system is built to handle high-traffic areas like kitchens, warehouses, and industrial floors where spills and moisture are frequent. It holds up against winter snow, road salt, and scorching summer heat without cracking or peeling. Plus, it achieves full chemical resistance just 72 hours after installation. The quick installation process and comprehensive warranty make it an appealing option for commercial spaces.

One-Day Installation and Lifetime Warranty

Croc Coatings completes most installations in just one day, reducing the risk of moisture interference during curing. Foot traffic is allowed within 6–8 hours, and vehicles can safely return after 24 hours. The system reaches its peak performance between 36 and 48 hours.

The Penntek Evolution system also comes with a limited lifetime warranty that covers peeling, cracking, and fading. This warranty applies to both residential and commercial installations across North Idaho and Eastern Washington, including Spokane and Tri-Cities, WA, ensuring long-term protection against moisture-related damage.

Conclusion

Managing moisture is the cornerstone of a successful concrete coating. While a dry surface might seem ready, it can conceal higher internal moisture levels. Without proper testing, the durability of the coating becomes uncertain.

The in-situ Relative Humidity (RH) test (ASTM F2170) stands out as the most dependable method. By measuring moisture at 40% of the slab’s depth, it reveals the true conditions the coating will face once sealed. On the other hand, surface tests, like the calcium chloride method, only assess the top inch of the slab. This can miss hidden internal moisture, which often leads to peeling and blistering. Jason Spangler from Wagner Meters highlights these risks, emphasizing that premature coating can result in peeling, blistering, and de-bonding.

Another critical factor is surface preparation. Skipping steps like removing oil and grease, filling cracks with low-shrinkage materials, or creating the right surface profile through acid etching or mechanical grinding often leads to coating failures. When moisture levels are high, additional drying time, vapor barriers, or specialized primers designed for high-moisture environments become essential. These steps highlight the importance of choosing a coating system built to handle moisture challenges effectively.

Croc Coatings tackles these issues with its Penntek Evolution system, a cutting-edge solution that chemically bonds within the concrete pores, offering strength four times greater than traditional epoxy. Its one-day installation reduces the chance of moisture interference during curing, and the lifetime warranty ensures protection against peeling, cracking, and fading. Croc Coatings serves North Idaho and Eastern Washington, including Spokane and the Tri-Cities, providing long-lasting results homeowners can trust.

FAQs

What moisture level is safe to coat concrete?

To coat concrete effectively, the moisture level should be 5% or less. This ensures the surface is safe for application and minimizes the risk of coating problems. You can measure this using tests such as ASTM F2170 or ASTM F1869, which help confirm the surface’s readiness.

Which concrete moisture test should I use?

To measure moisture levels up to 1 inch below the surface of a concrete slab quickly and without causing any damage, consider using a non-destructive electronic moisture meter, like the ASTM F2659. This tool offers dependable results while keeping the concrete intact.

How can I speed up slab drying before coating?

To accelerate slab drying, focus on controlling the environment. Start by reducing the surrounding humidity – dehumidifiers, particularly desiccant-based models, are highly effective for lowering the dew point and promoting moisture evaporation. Pair this with increased temperatures, as applying heat can speed up the process. However, make sure to maintain proper airflow to evenly distribute heat and remove moisture-laden air.

Always monitor moisture levels carefully during this process. Excessive heat or insufficient drying can lead to coating failures, which can be costly to fix. By managing these factors, you’ll create the right conditions for a dry, ready-to-coat surface.

Related Blog Posts

- Pre-Installation Checklist: Concrete Floor Coating

- Preventing Moisture-Related Coating Failures

- How MVER Testing Protects Concrete Coatings

- How to Test Concrete Moisture Before Coating