How Penntek Coatings Pass Impact Resistance Tests

February 18, 2026

Penntek coatings are built to handle heavy impacts without cracking or peeling, making them ideal for high-traffic areas like garages, patios, and industrial floors. Unlike epoxy, which is more brittle, Penntek’s polyurea formula flexes under pressure, absorbing impacts and preventing damage. These coatings meet rigorous ASTM D2794 standards, ensuring durability under dropped tools, heavy machinery, and extreme temperatures.

Key Highlights:

- Impact Resistance: Tested with ASTM D2794, Penntek coatings resist cracking and peeling under sudden force.

- Material Advantage: Polyurea offers 98% greater elongation and 4x more durability than epoxy.

- Temperature Tolerance: Withstands up to 266°F sustained heat and 430°F short-term peaks.

- Quick Installation: Walkable in 12 hours, fully functional in 24 hours.

- UV Stability: No yellowing or degradation in sunlight.

- Hammer Test: Demonstrates resilience against repeated strikes.

Penntek coatings combine durability with flexibility, ensuring long-lasting protection for residential and commercial spaces. With proper installation, they provide a reliable solution for tough environments.

Epoxy vs Polyurea Hammer Impact Test | Penntek | Apex Concrete Coatings

sbb-itb-a0e5ae3

What Is Impact Resistance Testing?

Impact resistance testing evaluates how well a coating can handle sudden force, like a dropped tool or the strike of heavy equipment, without cracking or peeling. This test mimics real-world scenarios to determine whether a coating stays intact or fails under pressure. By applying a specific amount of energy to the coating, the test measures its ability to endure impact.

One of the most commonly used standards for this test is ASTM D2794, last updated on January 25, 2024. In this method, a weighted ball is dropped from varying heights onto a coated panel, creating a dimple. Inspectors then check the coating for cracks, peeling, or other signs of failure.

"This test method for impact resistance has been found to be useful in predicting the performance of organic coatings for their ability to resist cracking caused by impacts".

How Impact Resistance Is Measured

The ASTM D2794 standard uses a simple yet effective approach: a weighted spherical ball assembly drops from specific heights onto the coated surface. The energy absorbed by the coating before it fails is recorded in inch-pound units. A similar method is described in ISO 6272 Part 1, which uses a 1 kg weight and a 20 mm diameter spherical indenter.

After the impact, inspectors use both visual checks and diagnostic tools to identify cracks or other damage. Testing can be conducted in two ways:

- Direct impact: The weight is dropped directly onto the coating, simulating scenarios like a dropped tool.

- Reverse impact: This measures how well the coating adheres and flexes when the substrate bends or deforms.

The greater the height or energy required to cause damage, the better the coating’s durability. Additionally, the test provides insights into the coating’s curing quality. Under-cured coatings lack the strength to resist impacts, while over-cured ones can become brittle and prone to cracking. High-performance coatings, such as polyurea, manage to dissipate impact energy through molecular movement, reducing the risk of fractures.

These tests ensure that a coating can handle the stresses of everyday use while maintaining its protective properties.

Why Impact Resistance Matters for Concrete Coatings

The ability of a coating to absorb impact energy is directly linked to its real-world durability. For homeowners and businesses, this is essential when evaluating a coating’s longevity. Everyday occurrences – like dropped tools, rolling carts, or falling equipment – can stress the surface. Coatings that fail impact resistance tests may chip or crack quickly, leaving the concrete vulnerable to moisture, staining, and further damage.

When choosing a concrete coating, it’s crucial to check whether it meets ASTM D2794 standards. This ensures the product can withstand the wear and tear of high-traffic areas. Temperature is another important factor. Extreme heat or cold can make coatings brittle and more likely to crack. Professional-grade products, such as Penntek polyurea concrete coatings, are specially designed to maintain flexibility and strength across a wide range of temperatures, offering reliable protection in various conditions.

How Penntek Coatings Perform in Impact Resistance Tests

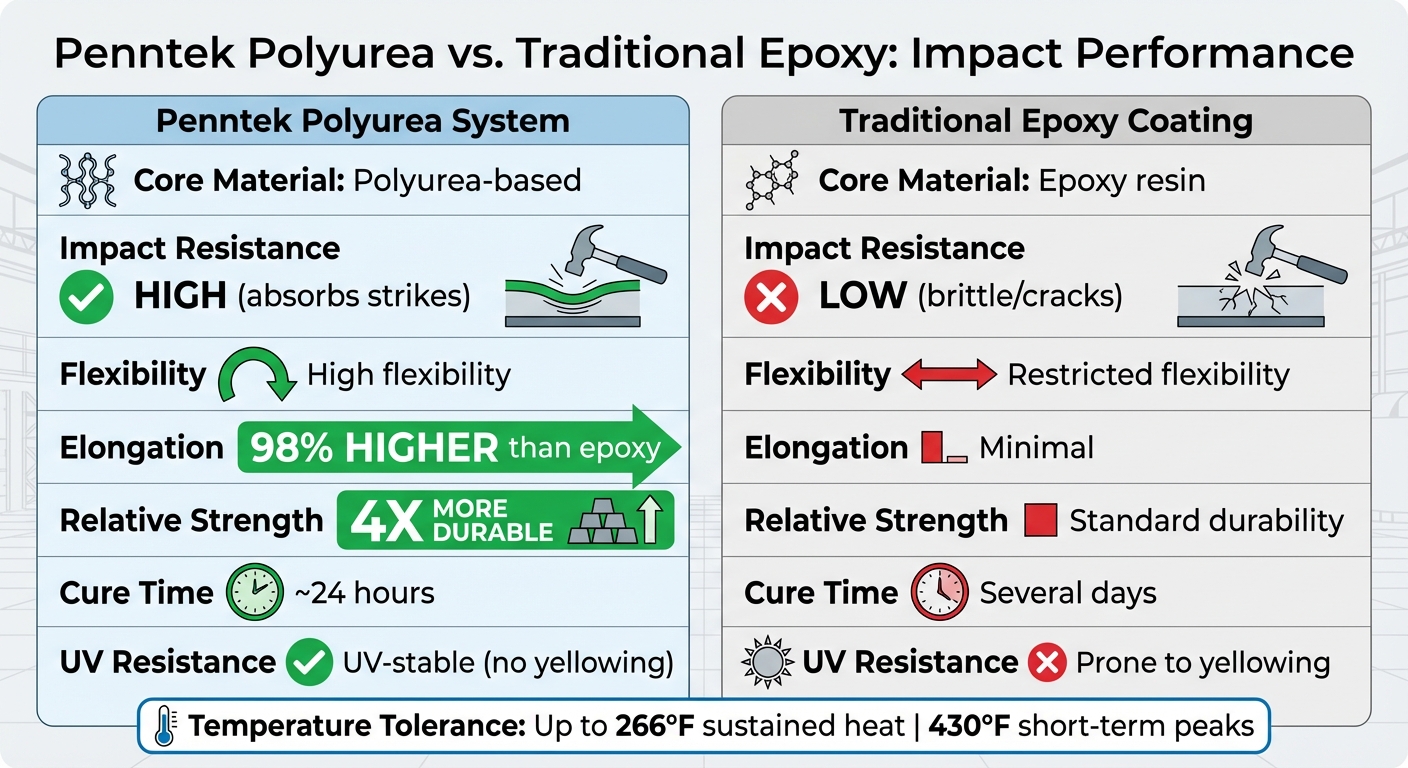

Penntek Polyurea vs Traditional Epoxy Coating Performance Comparison

Using ASTM D2794 testing methods as a foundation, Penntek’s coatings showcase impressive performance in impact scenarios. Thanks to their polyurea-based composition, these coatings are designed to flex under pressure, which helps absorb impacts and prevents cracking. Unlike rigid materials, this elastomeric formula stretches when force is applied, spreading the impact energy across a larger area. This design avoids the fractures commonly seen with brittle epoxy surfaces.

Penntek polyurea coatings boast 98% greater elongation and are 4x more durable compared to traditional epoxy coatings. When heavy tools or equipment hit the floor, the coating moves with the concrete beneath it rather than breaking apart.

Additionally, these coatings can handle sustained heat up to 266°F and short-term peaks of 430°F. This heat resistance ensures the material remains flexible, even under extreme conditions. Unlike epoxy coatings, which can yellow and degrade with UV exposure, Penntek polyurea remains UV-stable, retaining both its appearance and protective qualities even in direct sunlight. This resilience in harsh climates is further demonstrated through the hammer test.

The Hammer Test: Measuring Durability

The hammer test provides a clear demonstration of Penntek’s durability. When subjected to repeated strikes from a hammer – simulating real-world conditions like dropped tools or heavy impacts – Penntek polyurea absorbs the force without chipping or delaminating.

This test replicates the challenges faced in environments such as garages, warehouses, and industrial facilities, where floors endure frequent impacts. Penntek dealers often use this demonstration to highlight the differences between brittle epoxy, lower-grade polyurea, and their industrial-grade Certified Polyurea formula.

Polyurea vs. Epoxy: Impact Performance Comparison

A direct comparison underscores the advantages of Penntek polyurea over traditional epoxy coatings.

| Feature | Penntek Polyurea System | Traditional Epoxy Coating |

|---|---|---|

| Core Material | Polyurea-based | Epoxy resin |

| Impact Resistance | High (absorbs strikes) | Low (brittle/cracks) |

| Flexibility | High flexibility | Restricted flexibility |

| Elongation | 98% higher than epoxy | Minimal |

| Relative Strength | 4x more durable | Standard durability |

| Cure Time | ~24 hours | Several days |

| UV Resistance | UV-stable (no yellowing) | Prone to yellowing |

The faster cure time of Penntek coatings is another key factor in their durability. With a curing period of around 24 hours, they achieve full strength quickly. On the other hand, epoxy coatings take several days to cure, and improper curing can lead to coatings that are either too soft or too brittle – both of which compromise their impact resistance.

How Croc Coatings Uses Penntek Evolution System

Croc Coatings is the exclusive certified installer of Penntek Industrial Coatings in North Idaho and Eastern Washington. Owner Jim Hobart highlights a key challenge in the region:

"Epoxy floors just don’t stand up to the freeze/thaw cycles we encounter here in the Northwest."

This dedication to durability starts with meticulous preparation. Their team of 20 certified professionals uses 750-lb diamond grinders to properly profile concrete surfaces before applying the coating. This step ensures strong adhesion, allowing surfaces to become walkable within 12 hours and fully functional in just 24 hours.

Applications for High-Traffic Areas

The Penntek Evolution system is designed to handle tough conditions in high-traffic areas like garages, patios, pool decks, entryways, and industrial floors. Whether for residential or commercial use, this polyurea-based coating offers exceptional performance indoors and outdoors. Its 100% UV stability prevents fading under direct sunlight, while its impact resistance protects against chipping and peeling caused by heavy tools or equipment.

To back up their quality, Croc Coatings offers a limited lifetime manufacturer’s warranty and carries a $2 million liability policy, ensuring peace of mind for their customers.

Croc Coatings’ Hammer Test Video

Croc Coatings demonstrates the durability of the Penntek system on their YouTube channel with videos like The Durability Test and The Stretch Test. These clips showcase how well the coating holds up under extreme stress, proving its reliability in demanding situations.

Conclusion

Penntek coatings offer outstanding impact resistance, ensuring long-term durability for both residential and commercial spaces. These coatings undergo rigorous durability and stretch tests, proving their ability to handle heavy impacts and physical stress without chipping, peeling, or cracking. This reliability is further backed by a lifetime warranty.

Proper installation plays a crucial role in achieving these results. Croc Coatings, the exclusive certified installer for North Idaho and Eastern Washington, uses industrial-grade 750-lb diamond grinders to expertly prepare concrete surfaces. This preparation ensures a strong bond and maximizes the coating’s impact protection. Their precise process contributes to the coating’s quick activation and long-lasting performance.

With a one-day installation process, downtime is minimal. Surfaces are walkable within 12 hours and fully functional after just 24 hours. Plus, the coating is 4x stronger than epoxy and performs reliably as one of the best concrete coatings for harsh climates.

For anyone looking to protect their flooring for the long haul, partnering with certified installers like Croc Coatings ensures that Penntek’s impact resistance delivers its full potential. Whether for garages, patios, pool decks, or industrial floors, this combination of engineered strength and expert installation provides the durable protection these surfaces need.

FAQs

What does ASTM D2794 actually test?

ASTM D2794 is a standard test method used to assess the impact resistance of coatings. It works by exposing both the coating and its substrate to sudden deformation, simulating rapid impacts. The goal is to evaluate how well the coating can resist cracking or other forms of damage under these conditions.

How does polyurea prevent chips and peeling?

Polyurea offers excellent protection against chips and peeling thanks to its ability to absorb impacts and its flexibility. This unique combination helps it endure repeated hits without cracking or coming apart, even when exposed to harsh weather. Its strength makes it a reliable choice for safeguarding surfaces in both homes and commercial settings.

What prep is required before installation?

To get your garage ready for Penntek coatings, start by clearing out the space to give full access to the floors. A few days before installation, move or organize your belongings using temporary storage options like portable storage units or tarps. This step ensures the area is free of obstacles.

For safety, keep children, pets, and delivery drivers out of the garage during the installation process. Taking these precautions will help the process go smoothly and efficiently.

Related Blog Posts

- Polyurea vs. Epoxy: Impact Resistance Compared

- ASTM D2794: Impact Resistance Test Explained

- How Polyurea Coatings Resist Wear Over Time

- Impact Resistance in Harsh Climates: Polyurea Benefits