Why Efflorescence Cleaning Matters Before Coating

December 16, 2025

Efflorescence – those white, chalky deposits on concrete – can ruin coatings if ignored. It’s caused by moisture carrying salts to the surface, and skipping proper cleaning leads to peeling, blistering, and discoloration. Worse, it signals deeper moisture issues that weaken concrete over time.

To ensure coatings last, start with thorough surface prep:

- Inspect for efflorescence, moisture, and damage.

- Use methods like brushing, grinding, or acid cleaners to remove salts.

- Test moisture levels to confirm the surface is ready.

In regions with harsh winters, like North Idaho, freeze-thaw cycles worsen the problem. Professionals often use advanced tools and techniques to address persistent issues and prepare surfaces for durable coatings. Ignoring this step risks costly repairs and shortens the lifespan of your coating.

Problems Caused by Skipping Efflorescence Cleaning

How Efflorescence Affects Coating Performance

When efflorescence isn’t properly cleaned, coatings end up adhering to loose, water-soluble salts instead of clean concrete. This leads to issues like peeling, blistering, and the formation of pinholes – problems that can show up surprisingly fast.

Peeling and flaking are especially common in high-wear areas, such as tire paths and joints. Blisters and bubbles form when moisture and salts trapped beneath the coating escape, creating raised spots that are easily punctured. Pinholes and small craters appear during curing as vapor pushes through, often clustering in low areas or near cracks where moisture movement is higher. On darker coatings, trapped salts can leave behind white, cloudy patches that are not only highly visible but also tough to fix without stripping the coating and starting over. These adhesion failures open the door to further moisture-related damage.

Moisture and Durability Issues

Efflorescence that isn’t dealt with also disrupts the way concrete handles moisture. Persistent moisture dissolves salts, weakening the coating’s adhesion over time. This means the coating won’t last as long, leading to costly repairs. You could find yourself paying for the original installation as well as additional removal, more extensive surface preparation, and recoating.

In some cases, ongoing efflorescence might signal deeper problems, like poor drainage, leaks, or groundwater issues. These underlying problems need to be addressed to avoid repeated failures.

Regional Conditions That Worsen Efflorescence

Certain regions, like North Idaho and Eastern Washington, face unique challenges. Freeze-thaw cycles in these areas push moisture through concrete slabs, increasing salt migration and efflorescence buildup. Deicing salts tracked indoors dissolve in meltwater, saturating the concrete, and eventually reappearing as visible efflorescence. These repeated cycles put extra stress on coatings, making them more prone to cracking, peeling, or spalling in areas affected by efflorescence.

Local factors can make things worse. For example, irrigation overspray from landscaping can keep nearby concrete damp, flushing more salts to the surface even after initial cleaning. Patios, walkways, and shop floors in low-lying areas often deal with standing water and repeated wet-dry cycles. These conditions encourage efflorescence to return, undermining coatings applied without properly assessing moisture levels.

What Causes Efflorescence and how to remove and prevent it

How to Clean Efflorescence Properly

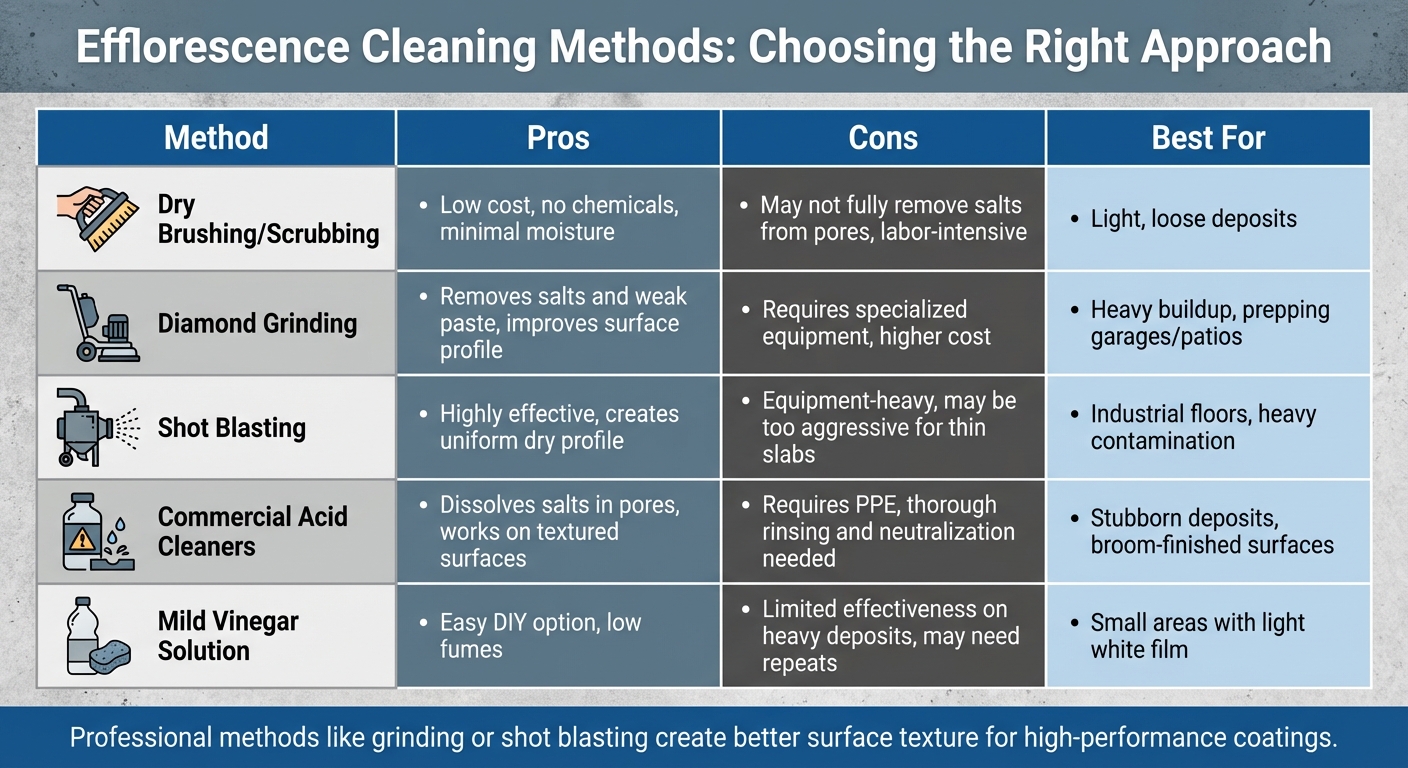

Efflorescence Cleaning Methods Comparison: Mechanical vs Chemical Approaches

Inspecting the Surface Before Cleaning

Start by closely examining the concrete for signs of efflorescence – white deposits, crusty buildup, or any areas showing deterioration. Pay special attention to spots like control joints, cracks, slab edges, and low areas where moisture tends to collect and escape.

To check moisture levels, use a plastic sheet test (leave it taped down for 24 hours) or an electronic moisture meter. The goal is to ensure levels meet coating standards, which typically range between 3–5 lb/1,000 sq ft/24 hr or 75–85% relative humidity. If moisture levels are too high, cleaning alone won’t fix the issue. You’ll need to address underlying problems, such as drainage or groundwater seepage, before moving forward.

Assess the overall condition of the concrete. If the slab is new, make sure it has cured for at least 28 days. To check for existing sealers, splash water on the surface – if it beads up, a sealer is present and must be removed before treating the efflorescence. Also, take note of any cracks, spalling, or soft spots, as aggressive cleaning methods could worsen these issues.

Once the inspection is complete, choose a cleaning method that matches the severity of the efflorescence and the condition of the surface.

Mechanical vs. Chemical Cleaning Methods

When it comes to removing efflorescence, you can opt for mechanical methods like brushing or grinding, or go with chemical cleaners, depending on the severity of the buildup.

| Method | Pros | Cons | Best For |

|---|---|---|---|

| Dry brushing/scrubbing | Low cost, no chemicals, minimal moisture | May not fully remove salts from pores, labor-intensive | Light, loose deposits |

| Diamond grinding | Removes salts and weak paste, improves surface profile | Requires specialized equipment, higher cost | Heavy buildup, prepping garages/patios |

| Shot blasting | Highly effective, creates uniform dry profile | Equipment-heavy, may be too aggressive for thin slabs | Industrial floors, heavy contamination |

| Commercial acid cleaners | Dissolves salts in pores, works on textured surfaces | Requires PPE, thorough rinsing and neutralization needed | Stubborn deposits, broom-finished surfaces |

| Mild vinegar solution | Easy DIY option, low fumes | Limited effectiveness on heavy deposits, may need repeats | Small areas with light white film |

For prepping surfaces that will receive high-performance coatings, methods like grinding or shot blasting not only clean but also create a better concrete surface profile for adhesion. Acid cleaners are particularly useful for textured or hard-to-reach surfaces but require careful handling and thorough rinsing to avoid residue.

Step-by-Step Cleaning Process

Once you’ve chosen your cleaning method, follow these steps for effective efflorescence removal:

- Sweep and Vacuum: Start by sweeping and vacuuming the surface to remove loose dirt and debris.

- Initial Dry Cleaning: Use a dry brush or mechanical scrubber to lift as much loose efflorescence as possible without introducing moisture.

- Moisture Check: Confirm the slab is dry enough to proceed by using a plastic sheet test or a moisture meter.

- Apply Cleaner: For stubborn deposits, apply the selected cleaner – whether it’s a commercial remover or a mild acid solution. Follow the manufacturer’s instructions for dilution and dwell time, and work in small sections to keep the surface wet.

- Agitate the Cleaner: Scrub the area with a stiff brush or rotary scrubber, paying extra attention to joints, low spots, and areas with visible crystal clusters.

- Rinse Thoroughly: Rinse the entire surface with clean water. Use a wet vacuum or squeegee to remove rinse water and prevent dissolved salts from resettling.

- Neutralize (if needed): If you used an acid cleaner, neutralize it with a mild alkaline solution, like baking soda dissolved in water. Rinse again with clean water.

- Final Drying: Allow the slab to dry completely, which could take 24–72 hours depending on the weather. Once dry, check moisture levels and visually inspect the surface to ensure all efflorescence is gone before applying any coatings.

sbb-itb-a0e5ae3

When to Hire a Professional for Efflorescence Removal

Signs You Need Professional Help

Sometimes, dealing with efflorescence goes beyond what DIY solutions can handle. For instance, if you notice persistent white deposits, it could mean ongoing moisture issues that basic methods just won’t fix.

Thick, crusty buildup that doesn’t respond to dry brushing or mild cleaners is another red flag. This kind of stubborn residue often requires industrial-grade removers and specialized tools, especially for large areas like driveways or garage floors.

Pay attention to damp spots, sweating concrete, or deposits that worsen after weather changes. These are signs of high moisture vapor emission rates moving through the concrete. Professionals can perform vapor transmission tests to measure these levels and may recommend solutions like vapor barriers or moisture-tolerant primers before applying any coatings.

Other warning signs include visible cracks, spalling, delamination, poor drainage, or standing water. These issues are especially concerning in colder regions like North Idaho and Eastern Washington, where snow, deicing salts, and temperature swings can make efflorescence worse.

If you’re planning to apply high-performance coatings, it’s crucial to start with a clean, bare concrete surface. Leftover efflorescence can lead to premature peeling or blistering, making professional removal a smarter investment than costly repairs down the line.

These challenges highlight why expert help is often necessary. Croc Coatings’ thorough preparation process is a great example of how professionals tackle these issues effectively.

How Croc Coatings Prepares Surfaces for Coating

When efflorescence and moisture problems are persistent, proper surface preparation becomes essential. Croc Coatings begins every project with a detailed inspection, including moisture and pH testing, to determine whether the surface is ready for the Penntek Evolution system. This step is crucial to identify whether the efflorescence is just a surface issue or a sign of deeper moisture concerns that need to be addressed before coating.

During the initial inspection, the team evaluates factors like drainage, exposure to snow and deicing salts, sprinkler overspray, and structural movement. In regions like the Inland Northwest, where harsh winters and heavy spring snowmelt are common, these conditions can significantly worsen efflorescence. Croc Coatings schedules work based on seasonal moisture patterns, ensuring slabs are dry enough for coating.

To prepare the surface, they use advanced methods like diamond grinding or shot blasting to remove contaminants and ensure optimal adhesion. For deeply embedded salts, they may turn to commercial efflorescence cleaners or controlled acid rinses, followed by thorough neutralization and rinsing to prevent salts from re-crystallizing.

Once the surface is prepped, it’s dried to meet strict moisture standards. This meticulous process ensures the Penntek Evolution coating – designed to be 4x stronger than epoxy – bonds perfectly, reducing risks of peeling, blistering, or discoloration caused by trapped salts or vapor pressure. This preparation also supports the system’s lifetime warranty.

In some cases, Croc Coatings may suggest additional measures like improving drainage, repairing cracks, or adding vapor-control base layers. These steps help extend the life of coatings applied to areas like garages, patios, and exterior entries that face freeze-thaw cycles and deicing salts.

Conclusion

Key Takeaways

Skipping efflorescence removal before applying a coating is a serious mistake. These salt deposits not only mar the look of concrete but also compromise the bond between the coating and the surface. If left untreated, coatings can start peeling, flaking, or failing within just six months – far short of their intended lifespan.

The foundation of a long-lasting coating lies in thorough surface preparation. By completely removing efflorescence, you ensure the coating adheres directly to clean and stable concrete, not to a fragile layer of salts. This stronger bond can increase the coating’s lifespan by 200–400%, allowing it to perform well for 20–30 years. In areas exposed to winter moisture, snowmelt, or deicing salts – conditions that amplify efflorescence – proper cleaning becomes even more critical.

The Role of Preparation in Coating Longevity

Effective preparation doesn’t just prevent immediate issues; it secures durability over the long haul. By following detailed surface preparation steps – like removing efflorescence, checking moisture levels, and profiling the surface – you can avoid common problems such as blistering, peeling, and discoloration.

Professional-grade preparation can add 5–10 years or more to a coating’s lifespan by addressing moisture vapor emissions, a frequent cause of flooring failures. For example, products like Croc Coatings’ Penntek Evolution deliver their best results only when applied to thoroughly cleaned and prepped surfaces. This meticulous process is what supports the lifetime warranties offered by Croc Coatings, ensuring that spaces like garage floors, patios, and commercial areas retain their look and functionality for decades.

FAQs

What causes efflorescence to appear on concrete surfaces?

Efflorescence happens when water travels through concrete, carrying dissolved salts with it. Once the water reaches the surface and evaporates, it leaves behind a white, chalky residue made of these salts. This issue is particularly common in places with high moisture exposure, like outdoor patios, pool decks, or basements.

It’s crucial to deal with efflorescence before applying any coatings. If left untreated, it can prevent coatings from sticking properly and weaken the durability of the finish. Removing it ensures the surface is clean and ready for a lasting application.

Why is it important to remove efflorescence before applying concrete coatings?

Efflorescence is that chalky white powder you might notice on concrete surfaces. It forms when moisture pulls salts from within the concrete to the surface. While it may seem harmless, it can seriously affect how well concrete coatings perform. Left untreated, efflorescence creates a fragile, porous layer that weakens adhesion, potentially causing the coating to peel, crack, or even delaminate over time.

Removing efflorescence before applying a coating is a must. A clean, solid surface ensures the coating bonds properly, resulting in a finish that’s not only smooth but also durable enough to handle the demands of both residential and commercial settings.

When should I hire a professional to remove efflorescence?

If the efflorescence is extensive, persistent, or doesn’t come off with typical cleaning methods, it might be time to bring in a professional. Proper removal is key to making sure concrete coatings stick well and last over time.

Experts come equipped with the right tools and know-how to completely eliminate efflorescence, leaving the surface ready for a durable, smooth finish. This is particularly crucial for high-traffic areas or spaces where a tough, dependable coating is a must.

Related Blog Posts

- Pre-Installation Checklist: Concrete Floor Coating

- Preventing Moisture-Related Coating Failures

- How to Clean Concrete for Coating Prep

- How to Test Concrete Moisture Before Coating