How Concrete Sealers Protect Your Driveway and Walkway In The Winter

February 12, 2026

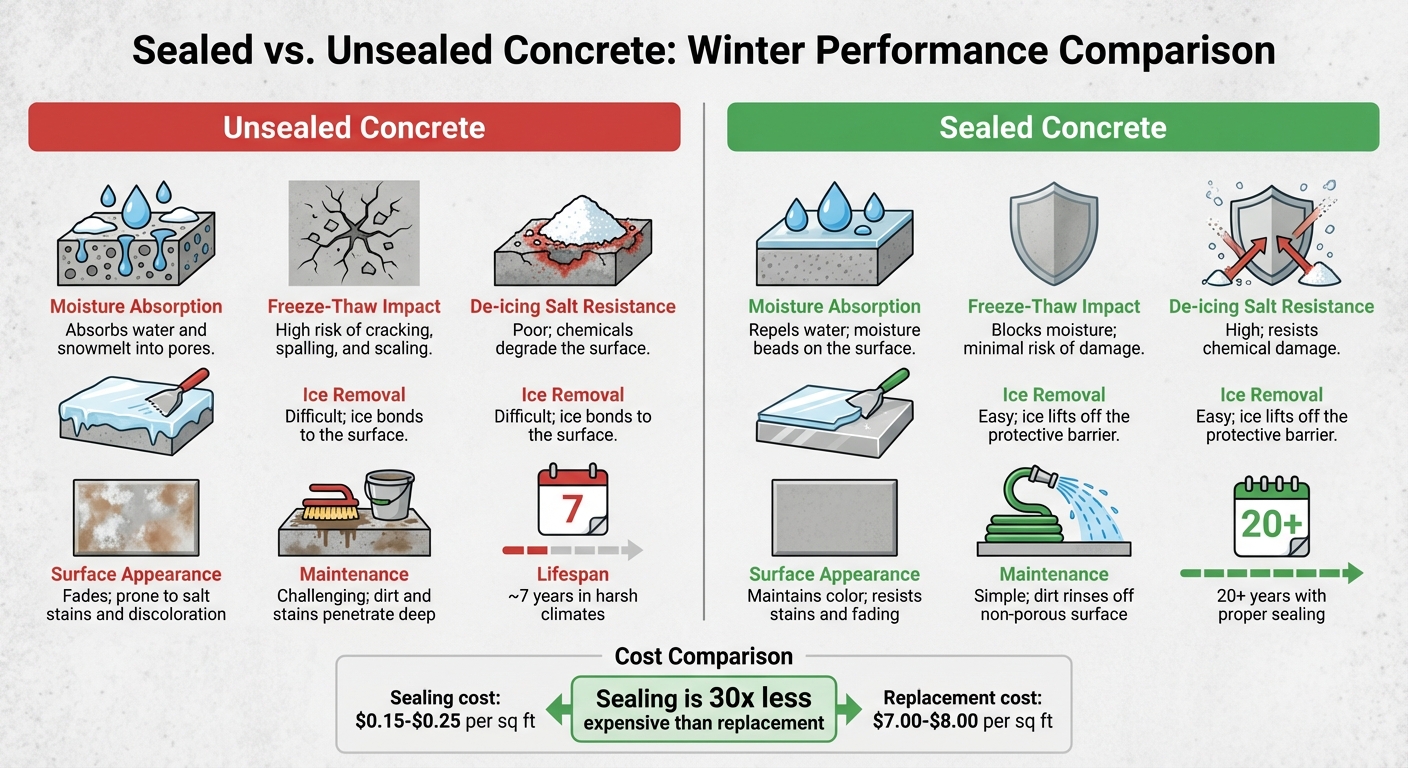

Concrete sealers are an effective way to protect your driveway and walkway from winter damage. Freezing temperatures, de-icing salts, and moisture absorption can cause cracks, scaling, and spalling in unsealed concrete. By applying a penetrating sealer, you create a barrier that repels water, reduces freeze-thaw cycles, and shields against chemical damage. Here’s why sealing makes sense:

- Prevents Cracks and Surface Damage: Sealer blocks water from entering the concrete, stopping freeze-thaw cycles that cause internal pressure and cracks.

- Protects Against De-Icing Chemicals: It resists salt damage, which can erode concrete and increase freeze-thaw stress.

- Saves Money: Sealing costs $0.15–$0.25 per square foot, while replacing damaged concrete can cost $7–$8 per square foot.

- Extends Lifespan: Sealed concrete can last over 20 years, compared to just 7 years for unsealed surfaces in harsh climates.

- Easier Winter Maintenance: Ice doesn’t bond to sealed concrete, making snow and ice removal simpler and safer.

For best results, seal your concrete in the fall before freezing temperatures arrive. A high-quality sealer can last 5–10 years, but resealing every 1–2 years may be necessary in colder regions. Protect your investment and avoid costly repairs by sealing your driveway and walkway before winter hits.

How Winter Damages Concrete

Freeze-Thaw Cycles and Cracking

Concrete has a porous structure that naturally absorbs moisture from rain, snow, and melting ice. When temperatures drop, the water inside freezes and expands by about 9%, creating internal pressures that can reach up to 100,000 pounds per square inch. This force is far greater than concrete’s tensile strength, leading to cracks.

The real trouble comes with repeated freeze-thaw cycles. As the ice melts, it leaves behind larger voids and widened cracks, allowing even more water to seep in during the next freeze. This cycle of damage often starts deep within the concrete, remaining hidden for years. In fact, in places like Kansas City, concrete can endure over 90 freeze-thaw cycles in just one winter. Sarah Etler, Content Marketing Manager at A-1 Concrete Leveling, describes it perfectly:

"Freeze-thaw cycles are like an endless tug-of-war between expansion and contraction, stressing concrete until it finally cracks under pressure."

By the time surface cracks, pitting, or spalling become visible, the internal structure is already severely weakened. In harsh climates, an unsealed driveway might last only about 7 years, while a properly sealed one can last over 20 years. Next, let’s take a closer look at how de-icing chemicals contribute to winter damage.

De-Icing Chemicals and Salt Damage

De-icing salts pose a serious threat to concrete in two key ways. First, they attract and retain moisture, keeping the concrete saturated even after the snow has melted. Second, these salts lower water’s freezing point, which significantly increases the number of freeze-thaw cycles. In fact, concrete exposed to salt can endure hundreds of these cycles in a single season.

The chemical reaction adds another layer of destruction. When salt brine penetrates concrete, it reacts with calcium hydroxide to form calcium oxychloride. This compound takes up more space than the original material, creating additional internal pressure that leads to cracking. The damage often appears as surface scaling – thin layers peeling off – or spalling, where larger chunks break away.

Certain de-icing products, such as those containing ammonium sulfate or ammonium nitrate, are particularly harsh and can erode concrete surfaces rapidly. Even common rock salt (sodium chloride), though less aggressive, becomes ineffective at temperatures below 15°F to 20°F. Despite this, it remains highly corrosive and can also harm nearby plants and landscaping.

These combined effects – moisture retention, chemical reactions, and repeated freeze-thaw stress – highlight the importance of protecting concrete surfaces during winter.

Moisture Absorption Problems

The more water concrete absorbs, the more susceptible it becomes to freeze-thaw damage. Unsealed concrete acts like a sponge, pulling moisture into its pores and cracks. Each freeze-thaw cycle worsens the damage, creating larger voids that absorb even more water during the next freeze. This cycle sets up a destructive feedback loop.

Poor drainage makes things worse by allowing water to pool on the surface, increasing absorption. Over time, microscopic damage grows into visible issues like pitting, flaking, and deep cracks. This accelerated deterioration ultimately leads to costly repairs and a shorter lifespan for the concrete.

sbb-itb-a0e5ae3

How Concrete Sealers Protect Against Winter Damage

Blocking Water and Chemical Penetration

Penetrating sealers are a game-changer when it comes to protecting concrete during winter. Unlike surface-level coatings, these sealers, such as Penntek Evolution, dive deep into the concrete pores, making them hydrophobic. In simple terms, they repel water instead of soaking it up. Some advanced sealers even crystallize within the concrete, filling up voids that would otherwise trap moisture.

What makes these sealers stand out is their "breathable" nature. They stop liquid water from seeping in while still allowing moisture vapor to escape from inside the concrete slab. This prevents pressure buildup, which could lead to cracks. By keeping water out, they ensure ice forms on top of the surface rather than bonding to it, making snow and ice removal much easier. This process significantly reduces the internal stress caused by freeze-thaw cycles.

Reducing Freeze-Thaw Damage

By repelling water, penetrating sealers remove the primary culprit behind freeze-thaw damage. Without water inside the concrete to freeze and expand, the risk of internal cracking and pressure is drastically reduced. This protection is especially important in regions with frequent freeze-thaw cycles. In such areas, resealing every 1 to 2 years may be necessary to maintain effective protection.

Under normal conditions, these sealers can last anywhere from 5 to 10 years, with silane-based formulas often providing a lifespan of 7 to 10+ years. To check if your sealer is still doing its job, try the water drop test. If water beads up on the surface, your concrete is protected. If it soaks in and darkens the surface, it’s time to reseal. This simple step not only prevents immediate damage but also helps maintain the concrete’s long-term durability.

Extending Surface Lifespan

Sealed concrete stands up better to winter conditions than unsealed surfaces. The barrier created by the sealer protects against water as well as de-icing salts, which can cause scaling and flaking over time. This results in fewer repairs, reduced maintenance costs, and a driveway or walkway that keeps looking good for years to come.

When it comes to costs, professional resealing typically runs between $1.50 and $3.50 per square foot. Compare that to the potential $20,000 price tag for replacing severely damaged concrete, and it’s clear why sealing is a smart investment. Chris Sullivan offers a practical tip for application:

"The most common application problem is applying too much sealer at once. Remember the phrase ‘thin to win’. Sealers are designed to perform best at a specific thickness."

What is the Best Sealer to Use to Protect My Concrete Against Freeze-Thaw Cycling?

Sealed vs. Unsealed Concrete Performance

Sealed vs Unsealed Concrete Performance Comparison for Winter Protection

When it comes to protecting concrete, sealed surfaces clearly outperform unsealed ones, especially in harsh conditions. One of the biggest differences lies in how they handle water. Sealed concrete creates a barrier that repels water, while unsealed concrete absorbs it. This absorption becomes a problem during freeze-thaw cycles. As water freezes, it expands, causing cracks and structural damage in unsealed concrete. Sealed concrete, on the other hand, prevents water from entering, keeping the structure intact even during repeated freezing and thawing.

Winter maintenance also becomes much easier with sealed concrete. On unsealed surfaces, ice bonds tightly to the porous material, making removal difficult and even unsafe. In contrast, sealed concrete creates a smooth barrier where ice simply rests on top. This makes it easy to remove with a shovel, as the ice "pops off" rather than sticking stubbornly to the surface.

The cost differences over time are another major factor. Sealing your concrete is about 30 times less expensive than replacing damaged surfaces. Bill York, a Technical Advisor at V-SEAL Concrete Sealers, sums it up well:

"In freeze-thaw climates, the expansion of frozen liquids can destroy the surface of unsealed concrete."

The table below provides a clear comparison of how sealed and unsealed concrete perform in key areas:

Performance Comparison Table

| Feature | Unsealed Concrete | Sealed Concrete |

|---|---|---|

| Moisture Absorption | Absorbs water and snowmelt into pores | Repels water; moisture beads on the surface |

| Freeze-Thaw Impact | High risk of cracking, spalling, and scaling | Blocks moisture; minimal risk of damage |

| De-icing Salt Resistance | Poor; chemicals degrade the surface | High; resists chemical damage |

| Ice Removal | Difficult; ice bonds to the surface | Easy; ice lifts off the protective barrier |

| Surface Appearance | Fades; prone to salt stains and discoloration | Maintains color; resists stains and fading |

| Maintenance | Challenging; dirt and stains penetrate deep | Simple; dirt rinses off non-porous surface |

| Lifespan | Shortened by weather and chemical exposure | Extended; preserves structural integrity |

Sealed concrete not only stands up better to winter conditions but also maintains its appearance. Unsealed surfaces often suffer from fading, salt stains, and oil discoloration, while sealed concrete resists these issues. Thanks to its non-porous barrier, cleaning sealed surfaces is as easy as rinsing them with a hose. These advantages make sealing a smart, long-term investment for protecting and preserving concrete.

How to Seal Concrete Surfaces for Winter

Preparing the Surface

Before sealing your driveway or walkway, take a close look for any cracks, potholes, or chipping. Sealers can’t fix structural damage – they only protect the surface as it is. Use flexible fillers or patching compounds to repair any cracks first. Skipping this step allows water to seep into the gaps, freeze, and expand, making the damage worse over the winter.

Next, give the concrete a deep clean. Use a degreaser and pressure washer to remove oil stains, algae, and dust. Once cleaned, wait 24 to 48 hours of dry weather before applying the sealer. You can test if the surface is dry by taping a 12×12-inch piece of plastic to it for two hours. If condensation forms underneath, the concrete is still too wet. Applying sealer to damp concrete traps moisture, which can lead to blistering or frost-like patches.

Once the surface is repaired and completely dry, you’re ready to apply the sealer for a smooth, protective finish.

Applying the Sealer

For an even application, use a pump sprayer with a fan tip and follow up with a 9-inch roller to smooth out any puddles. Make sure the concrete temperature is between 50°F and 80°F – use an infrared thermometer to check the slab temperature. Apply the sealer during the warmest part of the day to avoid issues like dew, frost, or condensation.

Opt for products like Penntek Evolution, which creates a water-repellent barrier and resists damage from de-icing chemicals. If you’re sealing late in the season, solvent-based sealers are a better choice than water-based ones, as they evaporate faster in cooler weather. Protect nearby surfaces by masking them off with painter’s tape or plastic sheeting.

A proper application ensures your concrete is ready to take on winter’s challenges, as outlined in the maintenance tips below.

Timing and Winter Maintenance

Timing is key – apply the sealer in the fall, before the first freeze. If the concrete is new, let it cure for at least 28 to 30 days before sealing. After applying the sealer, wait 4 to 6 hours before allowing light foot traffic, 24 to 48 hours for vehicles, and a full 72 hours before exposing the surface to rain or washing.

Once winter arrives, switch to plastic or rubber-bladed shovels to avoid scratching the sealed surface. Instead of rock salt, use sand for traction or safer alternatives like potassium chloride or calcium chloride. Spending around $200 on a good sealer can extend the life of a $10,000 driveway by 10 to 15 years – well worth the investment. In harsher climates, consider resealing annually to keep your concrete in top shape.

Conclusion

Winter doesn’t have to bring hefty repair bills and constant maintenance for your driveway and walkway. Using a high-quality penetrating sealer like Penntek Evolution from Croc Coatings can make all the difference. These sealers create a waterproof barrier, preventing moisture from seeping into the concrete’s porous surface. This simple measure stops freeze-thaw cycles from causing cracks and shields against de-icing chemicals that can erode the cement paste.

Here’s the math: sealing costs just $0.15 to $0.25 per square foot, while replacing damaged concrete can set you back $7.00 to $8.00 per square foot. Plus, penetrating sealers can protect your surfaces for 5 to 10 years or more, making it a smart and cost-effective choice.

By sealing before winter, you’re doing more than safeguarding your concrete – you’re cutting down on future maintenance expenses and keeping your property looking its best. Sealed surfaces also make snow removal easier and prevent small cracks from turning into big problems. This proactive step highlights the importance of quality sealers in maintaining both durability and curb appeal.

Don’t wait for winter to take its toll. Seal your concrete this fall and ensure your driveway and walkway are ready to withstand the toughest conditions, year after year.

FAQs

Which concrete sealer is best for freezing winters?

The Siloxa-Tek 8500 is a great choice for tackling freezing winters. It creates a hydrophobic barrier that keeps water from seeping into concrete surfaces. This helps protect against freeze-thaw cycles, ensuring your driveway and walkway stay strong and hold up against tough winter weather.

Can I seal concrete if it’s already cracked?

Yes, you can seal cracked concrete, but it’s important to repair the cracks first. Fixing the cracks helps stop further damage, especially from moisture and freeze-thaw cycles during winter. Once the repairs are done, sealing provides added protection and improves the durability of your concrete surfaces.

How do I know when to reseal my driveway?

You should reseal your driveway when you notice the sealant wearing down. Look for signs like more stains appearing, a dull or faded surface, or visible cracks and pitting. Generally, driveways need resealing every 2–3 years, but factors like the type of sealer, weather conditions, and how much the driveway is used can affect this timeline. Make it a habit to inspect your driveway regularly. If the sealant shows signs of wear, consider resealing before winter hits to guard against damage from freezing, thawing, and moisture seeping in.

Related Blog Posts

- How to Prepare Your Concrete Patio for Winter

- Salt-Resistant Concrete Coatings

- Protect Concrete from Salt Damage

- Protecting Stone-Look Patios in Harsh Climates