Concrete Coatings for Safer Showroom Floors

January 28, 2026

Automotive showrooms face unique challenges: high foot traffic, vehicle movement, and exposure to spills like oil, brake fluids, and coolants. Bare concrete floors absorb these substances, causing stains, structural damage, and slippery surfaces. Epoxy coatings are a common upgrade, but they often crack, yellow under UV light, and become dangerously slick when wet.

Polyurea coatings offer a better solution. They resist cracking, handle temperature changes, and provide excellent slip resistance – even in wet conditions. With a lifespan of over 15 years, they outperform epoxy in durability, chemical resistance, and UV stability. Croc Coatings‘ Penntek Evolution system, designed for automotive showrooms, features a quick one-day installation, custom colors, and a lifetime warranty, making it a reliable, long-term investment for safer, polished floors.

Which Concrete Coating Should You Use? | FULL COMPARISON

Problems with Bare Concrete in Showrooms

At first glance, bare concrete might seem like a practical flooring choice for showrooms. But over time, its porous nature turns it into a major headache. Concrete doesn’t just keep spills on the surface for easy cleanup – it absorbs them like a sponge. As JAK Concrete Coatings puts it:

Bare concrete is a porous material, which means it acts like a sponge. When a chemical spill occurs, it doesn’t just sit on the surface; it seeps deep into the pores.

This absorption not only speeds up the floor’s deterioration but also creates immediate safety concerns.

Slip Hazards from Spills and Moisture

When bare concrete comes into contact with moisture, oil, or automotive fluids, it can become dangerously slick. FloorTech Concrete Coatings highlights the risk:

Uncoated concrete and many epoxy coatings become hazardous when exposed to spills and moisture.

Because the surface absorbs these liquids, cleanup becomes more challenging, often leaving behind slippery residues. On top of that, substances like battery acids and harsh cleaners can etch the surface, creating rough areas that trap more contaminants and increase the risk of slips.

Appearance and Structural Damage

Beyond safety issues, bare concrete in showrooms quickly loses its appeal. Constant foot traffic and vehicle movement wear down the surface, leading to dust, stains, and a generally unkempt appearance.

Mike Wislinsky, Founder of Denver Floor Coatings, emphasizes the importance of a polished look:

First impressions matter, and stained concrete doesn’t sell cars.

Once automotive fluids seep into the concrete, the resulting stains become nearly impossible to remove. Over time, repeated exposure to chemicals and moisture causes cracks, spalling, and other structural damage. These flaws not only create tripping hazards but also tarnish the professional image of the showroom.

CustomCrete sums it up perfectly:

Worn-out flooring can cost you time, money, and professionalism. In a fast-paced automotive environment, a failing floor isn’t just an inconvenience – it’s a liability.

From safety risks to aesthetic and structural failures, bare concrete proves to be a poor long-term choice for showroom floors.

Limitations of Epoxy Floor Coatings

Epoxy coatings are a popular choice for showroom owners looking to upgrade from bare concrete. However, they often fall short when it comes to safety and durability. While epoxy provides some level of protection, it struggles to meet the rigorous demands of a modern automotive showroom.

Durability and Brittleness Problems

Epoxy hardens into a brittle surface that doesn’t handle stress well over time. Heavy vehicles and constant foot traffic can lead to chipping, cracking, and other damage. Poor surface preparation during installation can also shorten its lifespan.

A frequent issue is hot-tire pickup. When vehicles enter the showroom, the heat from their tires can soften the epoxy, causing it to stick to the tire and peel away from the concrete. Concrete Coatings Specialist Hayley Shahbazi highlights another concern:

Moisture is truly epoxy’s silent assassin.

Moisture beneath the concrete, known as hydrostatic pressure, can lead to bubbling, blistering, or even delamination of the coating.

Slip Resistance in Wet Conditions

Epoxy forms a smooth, non-porous surface, which becomes dangerously slippery when wet. Water, oil, and automotive fluids can increase the risk of slips and falls by as much as 40%. Unlike newer systems that incorporate textured finishes or decorative chips for added traction, standard epoxy often lacks these features. Over time, chemical spills can weaken the coating, causing it to bubble, peel, or soften. Its rigidity also makes it vulnerable to cracking as concrete naturally shifts with temperature changes. These cracks allow moisture to seep in, further undermining the floor’s integrity.

UV and Chemical Resistance Issues

For showrooms with large windows, UV exposure is another challenge. Sunlight can cause epoxy to yellow and fade over time. JAK Concrete Coatings explains how chemicals can exacerbate these issues:

Certain chemicals can cause epoxy to yellow, discolor, or soften, leading to bubbling and peeling.

Temperature shifts or minor movements in the concrete can also cause epoxy’s rigid surface to crack, creating openings for harmful chemicals to seep underneath. Automotive fluids like battery acid or brake fluid can quickly worsen the damage once they penetrate the coating. As JAK Concrete Coatings points out:

Epoxy is rigid. Temperature fluctuations or minor shifts in the concrete can cause it to crack, creating pathways for chemicals to penetrate underneath.

Another drawback is the curing time. Epoxy typically needs 72 hours to 7 days to fully cure before it can handle vehicle traffic. These limitations highlight the need for more advanced flooring solutions with better slip resistance and durability.

sbb-itb-a0e5ae3

How Polyurea Coatings Improve Showroom Floors

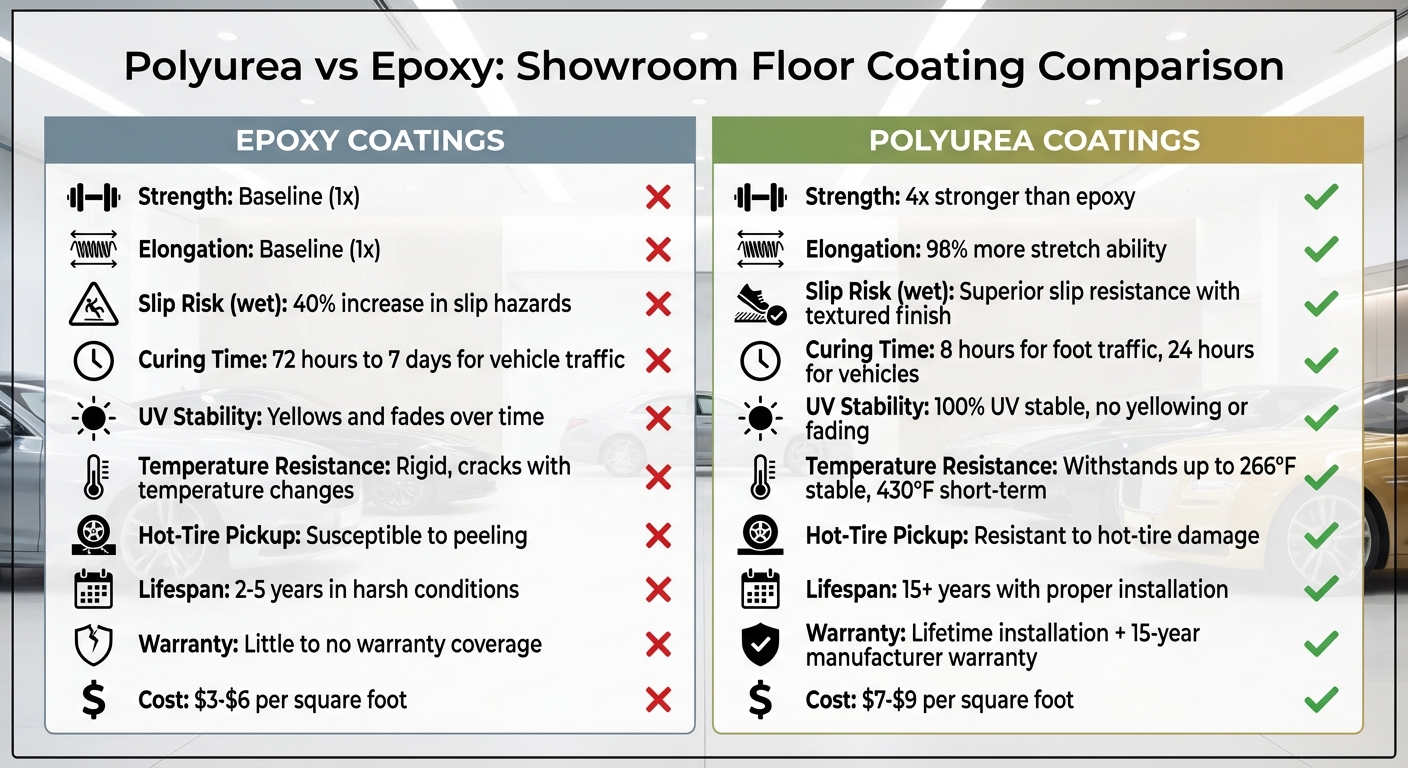

Polyurea vs Epoxy Showroom Floor Coatings Comparison

Polyurea coatings stand out by addressing the limitations of epoxy, offering 98% more elongation and four times the strength. This combination reduces cracking and absorbs impacts from heavy equipment and vehicle traffic, making it an excellent choice for high-traffic areas like showroom floors. Thanks to its flexibility, polyurea can move with the concrete during temperature changes, preventing the cracking that often occurs with rigid coatings. Croc Coatings highlights this unique feature:

Polyurea is an elastomer that has 98% more elongation (Stretch ability) than epoxy.

This flexibility not only enhances durability but also ensures better performance in demanding environments.

Superior Slip Resistance

In addition to its flexibility and strength, polyurea coatings deliver exceptional slip resistance. By incorporating a broadcast layer of sand or aggregate between the basecoat and topcoat, the surface gains a uniform texture that improves traction. This added grip remains effective even when the floor is exposed to water, oil, or automotive fluids. The coating’s non-porous barrier causes liquids to bead on the surface, preventing deep stains and ensuring consistent slip resistance across the entire floor.

Increased Durability and Lifespan

Polyurea’s flexible structure makes it highly resistant to impacts, avoiding the chipping and cracking seen in rigid epoxy coatings. Proper surface preparation ensures a strong bond, reducing the chances of peeling or delamination under heavy use. It also resists hot-tire pick-up and can endure stable heat up to 266°F and short-term exposures up to 430°F. When professionally installed, polyurea systems are built to last over 15 years. Plus, its rapid curing process allows foot traffic within 8 hours and vehicle traffic after just 24 hours.

Chemical and UV Stability

Polyurea’s durability extends beyond its physical properties, as it also offers excellent chemical and UV stability. Its dense, cross-linked molecular structure creates a tough barrier that repels chemicals, including oil, antifreeze, and brake fluid. These substances bead on the surface, making cleanup easy and preventing stains. Additionally, polyurea is 100% UV stable, meaning it won’t yellow or fade like epoxy coatings. As Andy Roe, Founder and CEO of Roe Paint, explains:

Polyurea is 100% UV stable and works great on outdoor surfaces. It won’t fade or discolor in the sun.

This combination of chemical resistance and UV stability ensures showroom floors stay professional-looking for years, without the need for frequent refinishing or touch-ups.

Croc Coatings‘ Penntek Evolution System for Showrooms

Croc Coatings has tailored the impressive benefits of polyurea coatings specifically for automotive showrooms, addressing key issues like slip hazards and durability head-on. Their solution? The Penntek Evolution system, a cutting-edge polyurea coating that’s four times stronger than epoxy, offering unmatched safety and a polished, professional finish.

This advanced system is now available for automotive showrooms across North Idaho and Eastern Washington, including Spokane and the Tri-Cities.

Key Features of the Penntek Evolution System

The Penntek Evolution system is built with a multi-layer design – typically three or four layers – that ensures exceptional strength and long-lasting adhesion. It also stands out with its UV protection, an essential feature for showrooms with expansive windows. Additionally, the coating includes antibacterial properties, making it a perfect choice for spaces where hygiene is a priority.

The system offers pre-tinted and custom color options, available in both high-gloss and matte finishes, and it maintains low VOC emissions for an eco-conscious solution.

As Penntek Industrial Coatings puts it:

With our polyurea shop floor system, you’ll never have to choose between beauty and strength.

Designed to handle extreme temperatures without cracking, this coating is also highly resistant to chemicals, abrasions, impacts, and scratches – ideal for the demands of a busy showroom.

One-Day Installation Process

One of the standout features of the Penntek Evolution system is its quick installation process. Croc Coatings can complete the entire installation in just one day, minimizing downtime for showrooms. The process includes industrial grinding and digital moisture monitoring to ensure optimal adhesion. For high-traffic automotive facilities, this rapid turnaround is a game-changer.

Lifetime Warranty and Long-Term Value

Croc Coatings backs the Penntek Evolution system with a lifetime installation warranty and a 15-year manufacturer’s warranty. This comprehensive coverage protects against common issues like peeling, chipping, and delamination caused by concrete movement. In comparison, many epoxy solutions offer little or no warranty, often lasting only 1–2 years in harsher conditions.

The system’s durability comes from its superior adhesion, as polyurea creates a permanent chemical bond with concrete, far outlasting the mechanical bond of epoxy. This means showroom owners benefit from a floor that stays UV stable, resists yellowing and fading, and withstands heat up to 266°F. While epoxy systems may need replacing within 2–5 years, the Penntek Evolution system is designed to last over 15 years.

This long lifespan not only reduces the need for costly replacements but also helps maintain property value. An attractive, warrantied floor can enhance the overall appeal of a commercial space and may even lead to better business insurance rates. To maintain optimal performance and keep the warranty intact, showroom owners should stick to nonabrasive cleaning materials and avoid harsh chemicals.

Conclusion

Automotive showrooms face a unique set of challenges – everything from slippery surfaces caused by spills or moisture to the constant wear and tear from heavy foot and vehicle traffic. Bare concrete and traditional epoxy coatings often fall short when it comes to meeting these demands. They lack the safety features, durability, and polished look that showrooms require.

This is where Croc Coatings’ Penntek Evolution system stands out. It’s designed to resist cracking, stay UV stable, handle exposure to automotive fluids, and maintain excellent slip resistance – even in wet conditions. While standard epoxy floors typically last just 2–5 years, polyurea coatings can deliver over 15 years of dependable performance. That kind of longevity is a game-changer for busy showrooms.

For showroom owners in North Idaho and Eastern Washington – including areas like Spokane and the Tri-Cities – Croc Coatings offers more than just a durable floor. Their one-day installation process minimizes downtime, and they back their work with a lifetime installation warranty, paired with a 15-year manufacturer’s warranty. The system is specifically engineered to handle the demands of high-traffic commercial spaces.

Although the Penntek Evolution system costs $7–$9 per square foot compared to $3–$6 for basic epoxy, its durability means fewer replacements and less hassle over time. If you’re ready to upgrade your showroom floor with a solution that prioritizes safety, durability, and long-term value, Croc Coatings has you covered. Their certified team ensures every surface is prepared to industrial standards and uses advanced moisture monitoring tools to guarantee decades of reliable performance.

FAQs

What makes polyurea coatings a better choice than epoxy for showroom floors?

Polyurea coatings are a top pick for showroom floors because of their exceptional toughness and ability to withstand heavy use. They’re designed to flex slightly, which helps prevent cracking over time, and they’re UV-stable, so they won’t yellow or fade when exposed to sunlight. On top of that, they’re highly resistant to chemicals, making them perfect for spaces where spills or cleaning products are frequently used.

When compared to epoxy, polyurea coatings stand out for their faster curing time and greater resistance to impacts. This means they deliver a polished, long-lasting finish that can handle the daily hustle and bustle of a showroom. Plus, polyurea creates a safer, slip-resistant surface, making it a reliable choice for maintaining a professional and secure environment.

How does the Penntek Evolution system reduce downtime during showroom floor installation?

The Penntek Evolution system offers a fast and efficient solution with its rapid-curing technology. From surface preparation to application, the entire installation is wrapped up in just one day. That means your showroom floor can be back in action within 24 hours, keeping downtime to an absolute minimum.

This speedy process not only saves valuable time but also lets your business keep running smoothly, making it an ideal choice for bustling commercial spaces.

Why are polyurea coatings better at resisting UV rays and chemical damage compared to epoxy?

Polyurea coatings stand out as a superior choice compared to epoxy, especially in their ability to handle UV exposure and chemical wear. Thanks to their 100% UV stability, they resist fading, discoloration, and degradation, even after prolonged sun exposure. On top of that, polyurea offers strong resistance to harsh chemicals, salt, and gases, making it an excellent long-term option for demanding environments that need reliable protection and performance.

Related Blog Posts

- Top 5 Benefits of UV-Stable Polyurea Coatings

- How Polyurea Coatings Resist Wear Over Time

- Polyurea vs. Epoxy: Chemical Resistance Compared

- How Polyurea Protects Floors from Oil and Grease