Common Garage Floor Paint Mistakes and Fixes

February 9, 2026

When painting your garage floor, the biggest mistakes often boil down to skipping prep, rushing the process, or ignoring weather conditions. These errors can lead to peeling, bubbling, or even total coating failure. Here’s what you need to know upfront:

- Surface Prep Is Key: Most failures happen because the floor wasn’t cleaned, degreased, or textured properly. Proper surface preparation includes scrubbing, removing oils, and ensuring the concrete has the right texture for paint to bond.

- Moisture Matters: Moisture in concrete causes bubbling and peeling. Use a plastic sheet or calcium chloride test to check for issues before starting.

- Weather Counts: Paint won’t cure properly if it’s too hot, too cold, or too humid. Stick to 60°F–80°F and keep humidity under 70%.

- Mixing Must Be Precise: Incorrect resin-to-hardener ratios or poor mixing can ruin the coating. Use a drill with a paddle and follow the product’s instructions exactly.

- Don’t Rush Curing: Even if the floor feels dry, wait 5–10 days before driving on it to prevent damage like tire pickup.

For a longer-lasting option, professional systems like Croc Coatings‘ Penntek Evolution use polyurea instead of epoxy, offering better durability, UV resistance, and a chemical bond that lasts over 15 years. While DIY kits cost $3–$6 per square foot, professional options range from $7–$9 but come with a lifetime warranty and fewer headaches.

Proper planning and patience can save you time, money, and frustration in the long run.

How To Paint Your Garage Floor – Learn From My Mistakes!

sbb-itb-a0e5ae3

Mistake 1: Poor Surface Preparation

Getting the surface ready is a step you can’t skip. In fact, 95% of epoxy floor issues, whether it’s peeling, bubbling, or complete failure, can be traced back to poor preparation. If you don’t clean, etch, or grind properly, the paint won’t adhere – it’ll stick to dirt, oil, or a smooth surface instead. And that’s a recipe for disaster.

Epoxy and floor paints need a textured surface to bond. As All Garage Floors puts it:

"The most common reason by far for epoxy floor failures and/or bad finishes… involves much more than making sure it is clean. Epoxy will not adhere to a smooth surface."

So, before you start, your concrete must be squeaky clean, dry, and rough enough to hold the coating.

Cleaning and Degreasing the Surface

Start by clearing the area and sweeping away loose debris. Next, scrub the floor with TSP or an alkaline cleaner to eliminate the weak, dusty layer (called laitance) on freshly poured concrete. If the paint bonds to this layer instead of solid concrete, it’s almost guaranteed to fail.

For oil or grease stains, use a commercial degreaser. Apply it directly to the spots, scrub with a stiff brush, and let it sit for 10 minutes before rinsing. Ignoring this step can lead to "fisheyes" – those annoying circular imperfections where the paint refuses to stick.

After scrubbing, rinse the floor with a pressure washer to remove any leftover grime and chemicals. Then, let it dry for at least 24 hours. Vacuum and use a tack cloth to pick up any remaining dust, as even tiny particles can ruin the bond.

Here’s a quick trick: Pour a little water on the floor. If it beads up instead of soaking in, you’ve got contamination – like oil or a sealer – that needs to be removed before moving forward.

Once the surface is spotless, it’s time to check for moisture.

Checking for Moisture Problems

Even if the floor looks dry, moisture seeping through the concrete can cause bubbling, lifting, or total failure. PPG Paints warns:

"If there is a moisture problem, it’s very likely that you are not going to be able to coat the floor properly."

Moisture trapped in the concrete creates hydrostatic pressure as it tries to escape, which can push the coating off the surface – and sometimes even take chunks of concrete with it.

To test for moisture, start with the plastic sheet method. Tape an 18×18-inch sheet of plastic to the floor and leave it for 16–24 hours. If condensation forms underneath, you’ve got a moisture issue.

For more precise results, use a calcium chloride test kit (around $40 for three tests). This measures vapor transmission over 60 to 72 hours. Most epoxy coatings require moisture levels below 3 lbs. per 1,000 sq. ft. Rebecca Wright from Family Handyman advises:

"The maximum amount of water vapor penetration is 3 lbs. per 1,000 sq. ft. If your results show more than that amount, don’t even consider applying epoxy or any other paint-type coating to your garage floor."

For the most accurate readings, test during the spring when the ground is damp. And if you’ve recently pressure washed or etched the floor, wait 24–48 hours to let the moisture evaporate.

Once you’re confident the floor is dry, it’s time to create the right surface texture.

Creating Surface Texture

After cleaning and confirming the floor is dry, focus on texturing. Epoxy and floor paints need a rough surface to stick. You can achieve this by either acid etching or mechanical grinding, which opens up the concrete pores and removes the weak laitance layer.

Acid Etching is the go-to method for DIYers. Mix one part muriatic acid with three parts water (a gallon typically covers about 100 square feet). The acid reacts with the concrete, exposing its pores. But keep in mind, etching won’t remove sealers, deep oil stains, or tire residue.

Mechanical Grinding, on the other hand, is the professional approach. It physically removes the top layer of concrete, along with any old coatings or contaminants. Grinding creates a consistent texture – similar to 80–120 grit sandpaper – that’s ideal for bonding.

| Preparation Method | Best For | Limitations |

|---|---|---|

| Acid Etching | Bare, unsealed concrete; DIY projects | Won’t remove sealers, oil, or tire residue; requires 24+ hours to dry |

| Mechanical Grinding | Removing old paint/sealers; pro results | Needs specialized equipment; improper use can damage concrete |

| Degreasing | Removing surface oils and grease | Doesn’t create texture; must be followed by etching or grinding |

Always degrease before profiling. If you etch or grind over oil, you’ll just push the contaminants deeper into the concrete. After profiling, vacuum thoroughly – any leftover dust will interfere with adhesion.

Keep in mind, a well-prepped floor absorbs more material. Plan for up to 15% product loss due to absorption and residue left in containers. Proper preparation might take time, but it’s the foundation for a long-lasting finish.

Mistake 2: Painting in Wrong Weather Conditions

Once your surface is prepped, the next big factor is the weather. Even a perfectly prepared floor can be ruined if the environmental conditions aren’t right. Temperature and humidity play a huge role in how paint bonds and cures. Ignore these, and you could end up with bubbles, cloudiness, or a coating that never fully hardens.

When temperatures drop below 60°F, paint thickens, slowing down the curing process and leaving a soft, tacky finish. On the flip side, temperatures above 85°F speed up curing too much, which can trap air bubbles and leave visible brush marks.

Humidity is another big challenge. If moisture levels exceed 85%, you risk "amine blush" – a waxy, cloudy film forming on the surface. Plus, if the concrete itself holds too much moisture, it can lead to common problems with epoxy garage floors like blistering or peeling down the line . As UreChem Paints puts it:

"High humidity introduces moisture into the air that can interfere with your paint’s ability to dry and bond properly."

In areas like South Florida, neglecting these conditions is a major culprit behind epoxy coating failures, accounting for 70% of issues.

Best Temperature for Painting

The ideal temperature range for applying garage floor paint is between 60°F and 80°F, with the concrete itself at least 55°F to 60°F . This range ensures the paint spreads evenly and cures properly. For the best chemical bonding, aim for curing temperatures between 75°F and 84°F.

An infrared thermometer is a handy tool to check the floor’s surface temperature and avoid costly mistakes. If you’re working in hot weather, try painting early in the morning or late in the afternoon when it’s cooler. In colder months, running space heaters in the garage 24 hours before you start – and keeping them on during the 72-hour curing period – can make all the difference.

Checking Humidity Levels

Before you even open the paint can, grab a hygrometer to check that the relative humidity is below 70%. Also, verify that the surface temperature is at least 5°F above the dew point . Ideally, aim for about 35% humidity for concrete projects, as anything above 85% is a dealbreaker. High humidity not only slows the drying process but also introduces moisture into the curing phase, causing issues like amine blush, tackiness, and bubbling.

In very humid areas, a dehumidifier can be your best friend. Running it for 72 hours before and after painting can help maintain a stable environment.

| Condition | Recommended Range | What Happens if Ignored |

|---|---|---|

| Air Temperature | 60°F–80°F | Too Hot: Premature curing, bubbles, lap marks. Too Cold: Slow drying, soft finish. |

| Floor Temperature | 55°F–60°F (Minimum) | Too Cold: Paint won’t bond; peeling is likely. |

| Humidity | Below 70%–85% | Too High: Amine blush, tacky finish, blistering. |

Timing is also key. If you’ve recently pressure washed or etched the floor, give it at least 24 hours to dry completely . And for outdoor-facing garages, avoid painting in the morning when dew might still be present.

Mistake 3: Mixing Paint Incorrectly

Getting your prep work and timing just right is crucial, but the way you mix your coating can make or break the entire project. Even a small error – just 5–10% off in your measurements – can ruin the curing process and compromise the coating’s performance.

The key issue? Resin and hardener need to be perfectly balanced for the mixture to cure as intended. If the ratio is off, the coating won’t reach its promised mechanical strength. Adding too much resin or hardener leads to specific problems, as shown in the table below. Another common pitfall is mistaking weight ratios for volume ratios. Since hardeners are often less dense than resins, a 5:1 weight ratio might actually translate to a 3:1 volume ratio.

And then there’s the mixing technique itself. Stirring manually with a stick just doesn’t cut it. As Akis Apostolopoulos, General Manager at Ktisis, puts it:

"Epoxy mixing is not like an acrylic emulsion. It actually requires significant power to be mixed in order to get a uniform product."

But don’t go overboard – mixing too aggressively can trap air and create bubbles in the coating.

Following the Manufacturer’s Instructions

Precision is everything when it comes to mixing. Digital scales are your best friend for getting the ratios right, and if you’re working with pigmented resins, premix them to keep the pigment from settling. Professional-grade epoxy systems often have specific ratios like 2:1 or 4:1, while lower-end consumer products might use a simpler 50:50 mix. Also, make sure to stick with components from the same product line; mixing and matching is a recipe for failure.

Some products require an "induction period", which is a short waiting time after mixing. This allows the chemical reaction to stabilize before application, ensuring better results.

Mixing Thoroughly

For proper blending, use a high-speed corded drill equipped with a paddle attachment. Mix for 2–3 minutes, keeping the paddle fully submerged to avoid pulling air into the mixture. Scrape the sides and bottom of the bucket as you mix to ensure all material is incorporated evenly, but avoid scraping the very bottom or edges where unmixed material can linger. These areas often contain residue that can later cause sticky or soft spots on your surface. Once the mixture is uniform, apply it immediately to prevent it from curing too soon.

Working Within Pot Life

Once mixed, epoxy starts generating heat due to an exothermic reaction. If left sitting in the bucket, this heat speeds up the curing process significantly. High-solids epoxies typically have a pot life of about 30 minutes, but in warmer conditions, this window can shrink drastically – sometimes by half or more.

To avoid problems, pour the mixture out in ribbons right away instead of letting it sit in the bucket. Large batches can produce a lot of heat, and in extreme cases, they can even become a fire hazard. For example, a 5-kilo batch can get very warm if left unused.

| Mixing Error | What Happens |

|---|---|

| Too Much Resin | Soft, squishy surface with unreacted material bubbles |

| Too Much Hardener | Premature hardening in the bucket, resulting in a brittle finish |

| High-Speed Mixing | Trapped air bubbles and surface craters |

| Incomplete Blending | Spotty soft areas and uneven color |

Mistake 4: Applying Paint Too Thin or Unevenly

Trying to stretch your coating further than recommended is a recipe for disaster. When you skimp on material, the coating becomes weaker, leaving behind visible streaks, uneven coloring, and a lackluster finish. Even worse, thin layers are highly prone to hot tire pick-up – a situation where warm vehicle tires pull the coating right off the floor, often within just a few months of application.

This issue often arises because concrete naturally absorbs a significant portion of the first coat due to its porous nature. You can lose up to 15% of your material to absorption, so plan accordingly. For instance, if you’re working on a 350‑sq‑ft garage, you’ll need enough product to cover about 450 sq ft. And don’t underestimate the importance of using the right tools to get the job done properly.

Using the Right Tools

The roller you choose can make or break your project. Go for high-quality lint-free phenolic core rollers with a 3/8″ nap to achieve a smooth, professional finish. Before you start, preload the roller to remove trapped air and avoid bubbles. Apply the coating in a 3‑ to‑4‑foot "W" pattern, then back-roll in a perpendicular direction to create an even layer.

Here’s a tip from the pros: listen to your roller. According to All Garage Floors:

"A quiet roller means the epoxy is going on thick while a loud roller means it’s going on thin." – All Garage Floors

If your roller starts making a loud scraping noise, it’s a clear sign you’re overextending the product.

Following Coverage Guidelines

Once you’ve ensured an even application with the right tools, stick to the manufacturer’s coverage recommendations. These guidelines exist to ensure the coating performs as intended. Epoxy thickness can vary from 0.2 mils to 250 mils, depending on the product and the condition of the concrete. Covering more area than specified weakens the bond and creates a thinner wear layer, which won’t hold up under regular garage use.

If you’re working solo, take advantage of contraction joints or saw cuts in the concrete to divide the space into smaller, manageable sections. This approach helps you maintain a wet edge and avoids unsightly overlap marks between batches. By following these steps, you not only extend the life of your garage floor but also achieve a finish that looks and performs as it should.

Mistake 5: Using the Floor Too Soon

Even with perfect preparation and application, rushing the curing process can ruin all your hard work. It’s important to understand the difference between drying and curing. A floor that feels dry to the touch may still need 5–10 days to fully cure. Using the floor too early – whether walking, driving, or placing heavy objects – can lead to permanent damage like indentations, scratches, peeling, or "fisheyes" (areas where the coating detaches).

Vehicle tires, in particular, are a major culprit. They can exert up to 35 PSI, which can permanently deform a floor that hasn’t cured properly. As Chris Lavin, Owner of National Concrete Polishing, explains:

"83% of premature epoxy flooring failures stem from improper curing practices".

This statistic highlights just how critical patience is during the curing process.

Waiting for Proper Drying Time

While many coatings allow for light foot traffic – like walking in soft-soled shoes – within 24 hours, heavier activities require more time. Vehicle use, for example, demands extra caution. Ideally, you should wait at least 5–7 days before driving on the floor, though many professionals recommend waiting 10–14 days to avoid issues like hot tire pick-up. This problem occurs when the heat from recently driven tires softens the partially cured coating, causing it to stick to the tire and peel off when the vehicle moves.

Here’s a quick breakdown of typical curing times for different paint types:

| Paint Type | Touch Dry | Light Foot Traffic | Full Cure (Vehicle) |

|---|---|---|---|

| Water-Based Acrylic | 1–2 hours | 24 hours | 5–7 days |

| 2-Part Epoxy | 6–8 hours | 24–48 hours | 7–10 days |

| Polyurethane | 4–8 hours | 24–48 hours | 5–7 days |

Note: These timelines assume ideal conditions (around 70°F). Cooler temperatures or high humidity will slow down the process.

Before allowing vehicle traffic, try the coin test: press a coin into an out-of-the-way spot on the floor. If it leaves an indentation, the floor isn’t ready. Another clue is a lingering chemical smell, which indicates the coating is still curing.

Once you’ve waited the recommended time, take steps to protect the floor from moisture during the remaining curing period.

Preventing Moisture Damage

Moisture can be a sneaky threat during curing. If the floor is exposed to water or high humidity within the first 72 hours, you might see hazy patches, bubbling, or even weakened bonds in the coating. Additionally, until the coating achieves full chemical resistance (usually 7–14 days), spills could cause permanent staining or damage.

To avoid these problems, maintain a controlled environment. Keep the temperature between 60°F and 85°F, and if humidity climbs above 50–60%, use a dehumidifier. Proper ventilation is also key – curing requires oxygen and airflow for solvents to evaporate effectively.

Professional Solution: Croc Coatings‘ Penntek Evolution System

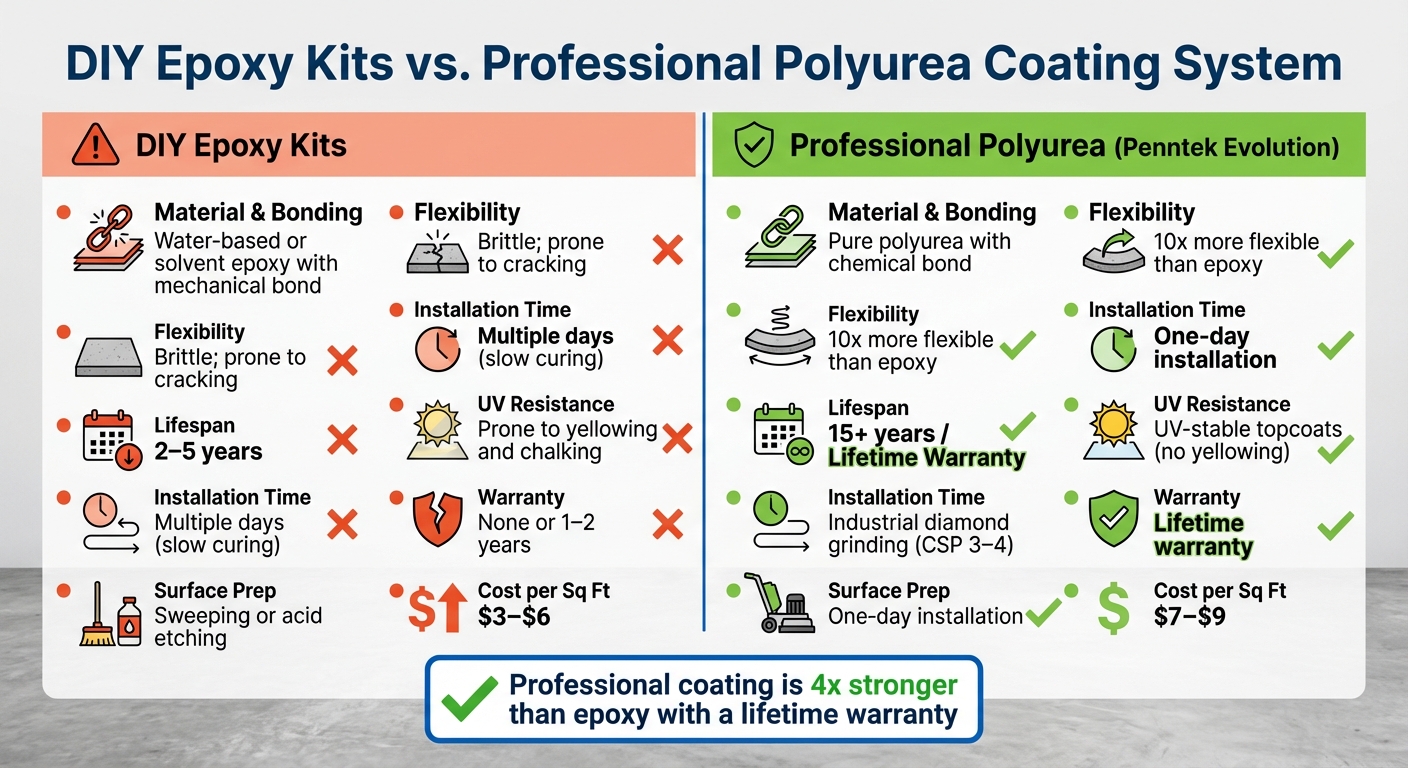

DIY Garage Floor Paint vs Professional Polyurea Coating Comparison

If you’re a homeowner in North Idaho, Eastern Washington, Spokane, or the Tri-Cities area, there’s good news: Croc Coatings offers a professional alternative to DIY garage floor coatings. Their Penntek Evolution system combines advanced materials with expert application, avoiding the common pitfalls of DIY projects – all in just one day.

Benefits of the Penntek Evolution System

The Penntek Evolution system replaces traditional epoxy with pure polyurea, a material known for its exceptional durability. Unlike epoxy, which forms a mechanical bond by sitting on top of the concrete, polyurea creates a chemical bond that directly fuses with the concrete surface. This bond, combined with polyurea’s flexibility – ten times greater than epoxy – makes it resistant to cracking during freeze-thaw cycles.

Croc Coatings also uses UV-stable topcoats, ensuring the finish won’t yellow or fade from sunlight exposure. The coating is resistant to oil, gas, antifreeze, and road salts, and it includes antimicrobial properties along with a slip-resistant texture for added safety.

With a lifespan of over 15 years, the system is backed by a lifetime warranty, far surpassing the short warranties (if any) that DIY kits provide.

One-Day Installation Process

Professional installation addresses the common mistakes that plague DIY projects, such as inadequate surface preparation, incorrect mixing, or applying coatings in unsuitable weather. Croc Coatings employs industrial-grade diamond grinders to achieve a Concrete Surface Profile (CSP) of 3–4, the industry standard for optimal coating adhesion. This method ensures a far better bond than the sweeping or acid etching often recommended in DIY kits.

Before applying the coating, technicians use tools like the Tramex CMEX5 to check for hydrostatic moisture levels. The installation process includes applying a polyurea basecoat, a decorative broadcast layer for added texture and strength, and a UV-stable topcoat – all with precision.

The entire process is completed in just one day, with the floor fully cured and ready for use within 48 hours. This quick turnaround bypasses the multi-day hassle of DIY projects, which often face risks like weather disruptions or improper mixing. As Jud Masters, VP of Sales at Roe Painting, points out:

"The #1 reason DIY epoxy garage floors fail is improper concrete preparation. Most kits say you just need to sweep, rinse, or maybe use an included ‘etching solution,’ but that’s not enough to get long-term adhesion."

DIY vs. Croc Coatings Comparison

Here’s a side-by-side look at how DIY epoxy kits measure up against the Penntek Evolution system:

| Feature | DIY Epoxy Kits | Croc Coatings (Penntek Evolution) |

|---|---|---|

| Material & Bonding | Water-based or solvent epoxy with mechanical bond | Pure polyurea with strong chemical bond |

| Flexibility | Brittle; prone to cracking over time | Ten times more flexible than epoxy |

| Lifespan | 2–5 years | 15+ years / Lifetime Warranty |

| Installation Time | Multiple days (slow curing) | One-day installation |

| Surface Prep | Sweeping or acid etching | Industrial diamond grinding (CSP 3–4) |

| UV Resistance | Prone to yellowing and chalking | UV-stable topcoats |

| Warranty | Typically none or 1–2 years | Lifetime warranty |

| Cost per Sq Ft | $3–$6 | $7–$9 |

The Penntek Evolution system addresses the major issues of DIY coatings, such as poor surface prep, moisture problems, and improper application. While the upfront cost is higher – $7–$9 per square foot compared to $3–$6 for DIY epoxy – the superior materials, professional installation, and lifetime warranty make it a smarter long-term investment. Over time, the durability and reduced need for repairs or reapplications can save you both money and effort.

Conclusion

Skipping proper surface prep, ignoring moisture issues, incorrect mixing, unsuitable weather, and rushing cure times are common culprits behind coating failures and expensive repairs. As Jud Masters, VP of Sales at Roe Painting, explains:

"If you skip proper surface prep, it’s not a matter of if your coating will fail, it’s when" (following a pre-installation checklist is essential for success).

DIY epoxy kits often fall short for several reasons. They typically rely on weak acid etching instead of industrial grinding, provide insufficient material – leading to issues like hot tire pickup – and lack UV protection, resulting in yellowing and brittleness within just a few years. These recurring problems highlight the risks of DIY solutions, making professional approaches a more reliable choice.

For homeowners in North Idaho, Eastern Washington, Spokane, or the Tri-Cities area, Croc Coatings offers a dependable alternative. Their Penntek Evolution system addresses the pitfalls of DIY kits with industrial-grade surface preparation and materials that are 4x stronger than epoxy. The one-day installation minimizes downtime, and a lifetime warranty ensures long-term peace of mind – something DIY options simply can’t provide.

While the upfront cost is higher, ranging from $7–$9 per square foot, the benefits far outweigh the expense. With a 15+ year lifespan and reduced maintenance needs, this system offers exceptional durability and value over time, combining professional expertise with superior materials for long-lasting results.

FAQs

How should I prepare my garage floor before painting it?

To get your garage floor ready for painting, start by completely clearing out the space – move out all items, vehicles, and furniture. Once the area is empty, give the floor a thorough cleaning. Sweep, vacuum, and wash away any dirt, dust, or debris to make sure the paint adheres properly.

Inspect the surface carefully for cracks, chips, or stains. If you find any damage, repair it to create a smooth, even foundation for the paint. Don’t skip testing for moisture in the concrete – too much moisture can stop the paint from bonding as it should. Lastly, make sure the area is well-ventilated. Open windows or use fans to improve airflow and reduce paint fumes. Taking these steps will help you achieve a durable, long-lasting finish for your garage floor.

How does weather affect garage floor paint application and durability?

Weather conditions can make or break the success of your garage floor paint. Extreme heat, cold, sudden temperature changes, or high humidity can cause issues like poor adhesion, bubbling, cracking, or even total failure of the coating. To get the best results, aim to apply the paint when temperatures are stable – ideally between 50°F and 85°F – and avoid days when the temperature is likely to swing dramatically.

Timing and preparation are everything when it comes to achieving a durable, long-lasting finish. For those seeking a high-performance option, professional-grade coatings, such as those from Croc Coatings, are built to handle challenging conditions while delivering a sleek, durable finish for your garage floor.

What makes polyurea a better choice than epoxy for garage floor coatings?

Polyurea is a standout option when it comes to garage floor coatings, especially when compared to epoxy. Its durability and flexibility set it apart, as it resists cracking or chipping even under heavy use. Unlike epoxy, which can struggle with wear and tear, polyurea handles impacts, chemical exposure, and temperature fluctuations with ease.

Another major advantage is its UV resistance. Polyurea doesn’t fade or yellow when exposed to sunlight, maintaining its appearance over time. Plus, it boasts a longer lifespan – lasting 10 to 15 years, compared to the 5 to 7 years you might expect from epoxy. For those seeking a coating that offers strength, longevity, and a sleek, polished look, polyurea is a smart choice for your garage floor.

Related Blog Posts

- 7 Signs Your Garage Floor Needs a New Coating

- 5 Tips for Preparing Your Space for a 1-Day Floor Coating

- Top Features of Specialty Garage Floor Paints

- DIY Garage Floor Coating Mistakes to Avoid