How to Assess Concrete Surface Profile

December 13, 2025

Concrete Surface Profile (CSP) is a standardized method to measure the roughness of concrete surfaces, crucial for ensuring proper bonding of coatings. The International Concrete Repair Institute (ICRI) developed a CSP scale (1–10) to classify surface textures, ranging from smooth to rough. Matching the correct CSP to a coating ensures durability, prevents failures like peeling or blistering, and meets manufacturer specifications, which are often required for warranties.

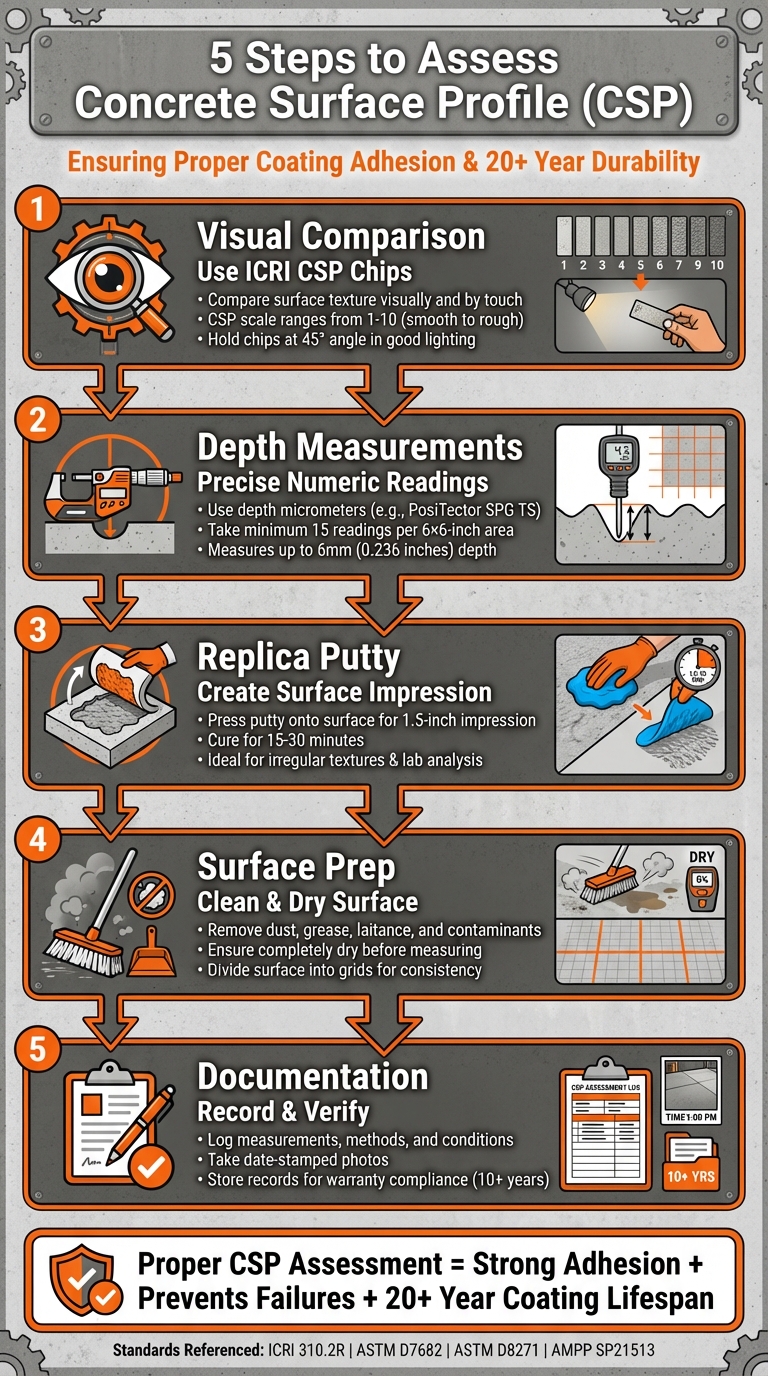

Key Steps to Assess CSP:

- Visual Comparison: Use ICRI CSP chips to compare the surface texture visually and by touch.

- Depth Measurements: Tools like depth micrometers provide precise numeric readings of surface roughness.

- Replica Putty: Create an impression of the surface for detailed analysis, especially for irregular textures.

- Surface Prep: Ensure the surface is clean and dry before measuring. Remove contaminants like dust or grease.

- Documentation: Record measurements, methods, and environmental conditions to ensure compliance and support warranties.

Why CSP Matters:

- Ensures proper coating adhesion.

- Prevents common concrete coating failures like delamination or uneven wear.

- Extends the lifespan of coatings, often up to 20+ years.

Proper CSP assessment combines visual tools, precise measurements, and thorough documentation to achieve long-lasting results.

5-Step Process to Assess Concrete Surface Profile (CSP)

CSP Standards and Measurement Tools

ICRI CSP Guidelines

The International Concrete Repair Institute (ICRI) has developed a standardized system to assess concrete surface profiles (CSP) across the U.S., detailed in their Guideline 310.2R. This guideline introduces the CSP 1–10 scale, which is widely used to evaluate the texture of concrete surfaces. To make this process more practical, ICRI provides rubber comparator chips – small rubber or plastic panels that function like paint swatches. By pressing these chips against a prepared surface, inspectors can visually and physically compare textures. Each chip corresponds to a specific CSP level, helping inspectors quickly determine if the surface meets the required profile. This approach reduces subjectivity and concerns like rust interference, laying the groundwork for consistent and reliable measurements as outlined below.

Tools for Measuring CSP

While the ICRI chips offer a straightforward way to assess surface profiles, there are also tools designed to provide precise, numeric measurements. Depth micrometers, such as the PosiTector SPG TS, are a popular choice. These devices comply with ASTM D8271 standards and feature a 1-inch diameter base that rests on surface peaks. A spring-loaded probe measures the depth of the valleys, with a range of up to 6 mm (0.236 inches). Inspectors typically take a minimum of 15 readings within a 6×6-inch area, discard outliers, and calculate the average and range. Modern digital gauges display profile depth in mils or micrometers and often include advanced features like statistical tracking, standard deviation, and HiLo alarms to flag readings outside specified limits.

For capturing irregular textures or creating a permanent record, replica putty (as per ASTM D7682) is another effective tool. This putty forms a 1.5-inch impression of the surface when pressed and allowed to cure. Once hardened, the replica’s peak-to-valley height can be measured with a micrometer or digital gauge, making it useful for lab analysis or resolving disputes. Additionally, AMPP SP21513 provides guidelines for determining conformance, specifying the number and locations of readings required to identify areas that do not meet the standard. These tools work together to confirm the profiles established by CSP chips.

Preparing Surfaces for CSP Measurement

Before taking CSP measurements, it’s crucial to ensure the concrete surface is clean and dry. Any residue – like laitance, dust, curing compounds, sealers, oil, or grease – can interfere with the reading by masking the actual profile. Similarly, standing water or slurry can obscure the texture, so the surface must be completely dry before measurements begin. To account for variability, divide the surface into grids. This is particularly important because edges often differ in texture compared to the center. Following procedures like those in AMPP SP21513, take multiple measurements in each grid section to check for uniformity and identify any over-prepared or under-prepared patches. If the project documents don’t specify the number or locations of measurements, it’s best to agree on these details during a pre-job meeting to ensure consistency and accuracy.

How to Assess CSP: Step-by-Step Methods

Visual and Tactile Comparison with CSP Chips

One of the easiest ways to evaluate the concrete surface profile (CSP) is by using ICRI CSP chips. These are molded rubber or plastic replicas that represent CSP levels from 1 to 10. Start by cleaning the concrete surface thoroughly and ensuring it’s completely dry. Then, in good lighting, hold the CSP chips at a 45° angle and visually compare the surface’s texture to the chips, focusing on the peaks and valleys. To refine the comparison, use your fingertip to feel both the chip and the surface. This combined use of sight and touch helps reduce subjectivity and provides a dependable assessment.

This method allows for quick verification. Be sure to examine multiple spots across the surface, as textures can differ between the edges and the center. Document each comparison with photos that show the chip next to the surface. If the texture falls between two CSP levels, note the range and choose the higher CSP number to ensure proper coating adhesion.

Measuring with Depth Micrometers

After using CSP chips for a visual assessment, depth micrometers provide precise, numeric measurements. Tools like the PosiTector SPG TS, used in line with ASTM D8271, are designed for this purpose. These digital gauges feature a 1-inch diameter base that rests on the surface’s peaks, while a spring-loaded probe measures the valleys in mils or millimeters, with a maximum depth of 6 mm (about 0.236 inches).

To use a depth micrometer, first prepare the surface and calibrate the device using the manufacturer’s reference plate. Within a 6×6-inch area, take at least 15 readings. Exclude extreme outliers caused by large pits or cracks, then calculate the average, range, and standard deviation. Many digital gauges can automatically display these statistics and flag any readings that fall outside acceptable ranges. For larger surfaces, take measurements at grid intersections spaced 10 to 20 feet apart to ensure a comprehensive analysis.

Using Replica Putty for Detailed Assessment

For surfaces where direct measurement is challenging, replica putty offers a practical solution. As outlined in ASTM D7682, this two-component epoxy putty creates a permanent impression of the concrete surface. When pressed onto the surface and allowed to cure for 15 to 30 minutes, the putty forms a 1.5-inch diameter replica. Once hardened, the replica can be measured with a micrometer or digital gauge to determine peak-to-valley height, either on-site or in a lab.

To use replica putty, mix the components until they’re uniform, then roll the putty into a ball. Press it firmly onto the concrete without sliding it. After curing, remove the replica and measure its peak-to-valley heights at several points. Average these readings and compare them to the CSP scale. For instance, a CSP 3 typically measures between 0.04 and 0.08 inches. This method is particularly helpful for irregular surfaces or when detailed documentation is required, such as for warranty-supported installations.

Matching CSP to Your Coating System

CSP Requirements for Different Coatings

Once you’ve nailed down the right technique for measuring Concrete Surface Profile (CSP), the next step is matching it to your coating system. Each type of coating has a specific CSP range it thrives in for proper adhesion. For example, light-duty coatings like sealers work best with CSP 1-3, while medium-build systems like epoxy paints need CSP 3-5. Heavy-duty industrial overlays? They require a more rugged CSP 5-9 to create a strong mechanical bond.

Take Croc Coatings’ Penntek Evolution system as an example. It’s designed for a CSP range of 4-6. This range strikes the perfect balance – deep enough for strong mechanical bonding but not so rough that it complicates installation. This sweet spot supports their one-day installation process and backs the lifetime warranty they offer for garage floors, patios, pool decks, basements, and industrial floors across North Idaho, Spokane, and the Tri-Cities. Getting the CSP right from the start can save you from headaches later, especially when deviations occur.

Fixing CSP Problems

If your CSP doesn’t align with the coating’s requirements, you’ll need to address it before moving forward. An insufficient CSP – where the surface is too smooth, with a profile under 2 mils – can lead to delamination because the coating lacks a proper mechanical grip. To fix this, use mechanical grinding with coarse diamond grits or opt for scarification or shot-blasting, depending on the CSP range you’re aiming for. Once corrected, thoroughly clean the surface of debris and re-measure to confirm you’ve hit the target profile.

On the flip side, an overly aggressive CSP – with deep valleys exceeding 20 mils – can cause issues like pooling, pinholing, or uneven coating thickness. To resolve this, apply polymer-modified cementitious patching compounds or self-leveling underlayments to fill the valleys. Afterward, perform light sanding to refine the surface to the desired CSP range. Finally, verify your adjustments using replica putty impressions.

How CSP Affects Coating Durability

Getting the CSP right isn’t just about avoiding immediate issues – it’s about long-term durability. A 2021 AMPP study revealed that CSP 3-5 offers the best adhesion for epoxies, with pull-off test results exceeding 200 psi. In contrast, CSP 1 showed 50% weaker bond strength, while CSP 8 and above led to uneven wear. For heavy-duty systems, CSP 5-7 supports coatings that are up to four times stronger than epoxy, reducing failure rates by 30-40% in high-traffic areas.

When the CSP is properly matched to the coating, the mechanical bond between the coating and concrete can extend its lifespan to over 20 years. However, mismatches can lead to specific problems: too-low CSP results in peeling and delamination, especially under heavy traffic like forklifts, while too-high CSP can cause thin spots and cracking, particularly on garage floors.

For Croc Coatings’ Penntek Evolution system, maintaining a CSP range of 4-6 ensures the coating delivers its full strength and abrasion resistance, which is four times stronger than epoxy. This precise preparation helps uphold their lifetime warranty by preventing adhesion failures that could arise from improper surface prep.

sbb-itb-a0e5ae3

Documenting CSP Assessments

Recording and Storing CSP Results

Once you’ve accurately measured the Concrete Surface Profile (CSP), proper documentation is key to ensuring quality and accountability. Start by recording all essential project details, such as the project name, address, date, concrete age, preparation method, equipment used, target CSP, achieved CSP, and the names of the inspectors. Environmental conditions like ambient temperature, slab temperature, relative humidity, dew point, and moisture test results should also be logged – these details can be critical for warranty claims.

High-resolution, date-stamped photos are incredibly useful for keeping a visual record. Take wide shots to capture the overall area, close-ups with the CSP chip or micrometer for scale, and before-and-after photos of any areas that needed rework. File names should be clear and consistent, such as "2025-12-15_SmithGarage_Bay1_CSP4.jpg", and link them to specific zones on a simple floor plan. Store all files in a reliable cloud-based system with regular backups, and keep these records for at least as long as the coating warranty lasts, which is often 10 years or more.

For complex projects with multiple areas – like garages, basements, or pool decks – divide the space into clearly labeled zones. Assign each zone a unique ID, and log CSP readings for each one. Use a table to organize details such as the preparation method, target CSP, measured CSP range, and any relevant notes. This structured approach ensures easy troubleshooting. For example, if peeling occurs in one corner of a garage years down the road, you’ll be able to quickly pull up the exact CSP records and installation conditions for that specific spot.

Following Standard CSP Procedures

Sticking to standardized procedures eliminates guesswork and ensures consistent quality across all projects and crews. Industry guidelines like ICRI Guideline 310.2R, ASTM D7682, ASTM D8271, and AMPP SP21513 provide a framework for accurate CSP measurement, reducing subjectivity and improving reliability.

Croc Coatings enhances these standards with its own best practices. For example, they document CSP both before and after repairs, use calibrated instruments across all teams, and set a minimum measurement density – such as one test area per 200 square feet – for garages, patios, pool decks, and basements. Their Penntek Evolution system is specifically designed to work within a required CSP range, so tying documentation directly to this requirement ensures strong adhesion and durability. This approach supports their lifetime warranty for customers in North Idaho and Eastern Washington. By following these procedures, they also create a solid foundation for training and quality assurance.

Training Resources for CSP Assessment

Good documentation and standardized procedures are the backbone of effective training programs. To ensure consistent application of the Penntek Evolution system, Croc Coatings relies on standard operating procedures, live demonstrations, and hands-on practice sessions.

Their YouTube channel complements these efforts by offering visual guides on CSP measurement techniques, common CSP targets for different surfaces, and real-world job walkthroughs. These videos also demonstrate how to properly photograph and log CSP before applying the Penntek Evolution system. Crews can access these resources on-site using tablets or smartphones, making it easy to follow the same process every time. This combination of training tools ensures that every team member delivers consistent, high-quality results.

Conclusion

Recap of CSP Assessment Steps

To achieve the right Concrete Surface Profile (CSP), start by identifying the ICRI CSP level required for your project. Prepare the surface to meet that target, then verify your work using both visual-tactile methods and precise measurement tools. Use CSP chips for a quick qualitative check, and rely on tools like depth micrometers or replica putty for accurate, quantitative verification. Inspect for any contaminants, laitance, or weak concrete that could compromise adhesion, and address any areas that are over- or under-profiled. Document all readings, locations, and dates in line with AMPP SP21513 guidelines. This combination of qualitative and quantitative checks ensures you have reliable, traceable proof that the surface is ready for coating. Each step enhances the substrate’s readiness, laying the groundwork for a durable and long-lasting coating.

Why CSP Matters for Coating Performance

The correct CSP is a key factor in determining how well a coating performs, especially in high-traffic or challenging environments like garages, warehouses, and pool decks. If the CSP is too low, coatings may peel or delaminate. On the other hand, an overly high CSP can cause issues like pooling and weak spots. Ensuring the profile matches the manufacturer’s specifications improves adhesion and extends the lifespan of the coating. Documenting this match not only reduces the risk of premature failure but also strengthens warranty claims if needed. Ultimately, taking the time to conduct a thorough CSP assessment is far more cost-effective than dealing with the fallout of a failed coating system.

Choose Croc Coatings for Superior Results

Croc Coatings understands the importance of CSP in achieving professional, long-lasting results. Their meticulous CSP assessment and documentation process ensures surfaces meet ICRI, ASTM, and AMPP standards, enabling one-day installations backed by a lifetime warranty. By combining ICRI CSP chips with precise quantitative checks, Croc Coatings delivers results homeowners and facility managers across North Idaho and Eastern Washington can trust. Their commitment to industry standards ensures the Penntek Evolution system, known for being "4x stronger than epoxy", performs as promised. With Croc Coatings, you’re not just protecting your coating investment – you’re safeguarding the value and durability of your concrete surfaces.

How to Measure Surface Profile with PosiTector SPG Digital Depth Micrometers

Measuring profile is a critical component of surface preparation for concrete coatings, ensuring the substrate is ready for optimal adhesion.

FAQs

What tools do I need to measure a concrete surface profile (CSP) accurately?

To measure a concrete surface profile (CSP) accurately, you’ll need a few essential tools: a surface profile gauge, a straightedge or ruler, and a depth comparator or surface roughness tester. These instruments are key to assessing the texture and roughness of the surface with precision.

Using the correct tools isn’t just about getting accurate readings – it also ensures the surface is prepared correctly for coatings. For example, products like those from Croc Coatings require specific CSP levels to achieve the best adhesion and long-lasting durability.

How does the concrete surface profile (CSP) impact the durability of coatings?

The concrete surface profile (CSP) is a key factor in determining how well a coating will perform over time. When the surface is prepared with the correct CSP, it creates a strong bond between the coating and the concrete, minimizing the risk of peeling or delamination. This bond is what helps the coating last longer and perform better under various conditions.

Getting the CSP right is especially important in areas like garage floors, patios, or industrial spaces where durability is non-negotiable. A well-prepared surface not only boosts the coating’s ability to handle daily wear and tear but also ensures it remains resilient in the long run.

What should I do if the concrete surface profile doesn’t meet the required standard?

If the concrete surface profile (CSP) falls short of the required standard, here’s what you can do to address it:

- Clean the surface thoroughly: Make sure to remove any dirt, oil, or debris that might interfere with the profiling process. A clean surface is essential for proper preparation.

- Use mechanical methods: Techniques like shot blasting, grinding, or scarifying can help you achieve the desired CSP. Choose the method that best suits your project needs.

- Consider a bonding primer: If necessary, apply a bonding primer to improve adhesion and ensure the coating sticks effectively.

- Reassess the profile: Before moving ahead, double-check that the surface meets the required profile standards. This step is crucial to avoid future issues.

For added peace of mind, it’s always a good idea to consult a coating expert. They can confirm that your surface is ready for the specific coating system you’re using. A well-prepared surface is key to ensuring the durability and longevity of your concrete coating.

Related Blog Posts

- Top Abrasion Tests for Concrete Coatings

- Concrete Surface Prep: Inspection Checklist

- Ultimate Guide to Surface Preparation for Concrete Coatings

- Concrete Surface Profiles Explained