Antimicrobial Testing for Concrete Coatings: Process Explained

February 17, 2026

Antimicrobial testing for concrete coatings ensures these products effectively reduce bacteria, viruses, and fungi while maintaining durability over time. This process evaluates coatings for:

- Residual Efficacy: The ability to kill microbes for hours or days after application.

- Resistance to Microbially-Induced Corrosion (MIC): Preventing structural damage caused by bacteria lowering concrete’s pH.

- Durability: Withstanding cleaning cycles, abrasion, and exposure to disinfectants like bleach.

Key testing methods include EPA MB-40, ASTM standards (e.g., E2180, C1904), and ISO protocols. These tests simulate real-world conditions to verify coatings meet EPA benchmarks, such as achieving a 99.9% microbial reduction (3-log) or higher. Results help ensure coatings maintain hygiene, prevent biofilm buildup, and resist long-term damage.

This testing is vital for spaces like restrooms, kitchens, and public areas, where coatings must balance hygiene with durability. Croc Coatings‘ Penntek Evolution system exemplifies this by combining antimicrobial protection with long-lasting performance.

Why Antimicrobial Testing Is Necessary for Concrete Coatings

Concrete coatings without antimicrobial protection face serious risks, including pathogen buildup and structural damage caused by biofilm-forming bacteria. These biofilms create a protective barrier that shields microbes from dehydration and disinfectants. The EPA highlights this issue by stating:

Bacteria in biofilm have the capacity to survive environmental stress and may serve as a reservoir of human pathogenic bacteria.

Testing ensures that coatings can effectively prevent harmful organisms like Staphylococcus aureus and Pseudomonas aeruginosa from thriving on surfaces.

This is especially critical in public spaces where routine manual disinfection isn’t feasible. For example, SARS-CoV-2 can persist on surfaces for hours or even days, with porous materials extending its survival time. Antimicrobial coatings provide a constant layer of protection, minimizing the survival of viruses and bacteria on high-touch surfaces without requiring constant intervention. These challenges highlight the need for thorough hygiene tests and durability assessments.

Hygiene and Safety Benefits

To receive EPA approval for biofilm elimination on hard surfaces, coatings must achieve a six log reduction – effectively eliminating 99.9999% of viable bacteria. However, standard antimicrobial tests using free-floating (planktonic) cells often fall short. Biofilm bacteria are genetically and metabolically distinct, making them much harder to eliminate .

In high-moisture areas like restrooms or locker rooms, testing against biofilms becomes particularly important. These microbial communities are highly resistant to environmental stresses, reinforcing the need for rigorous antimicrobial evaluations. Beyond immediate hygiene benefits, controlling pathogens also enhances the coating’s longevity by preventing microbially-induced damage.

Product Durability and Lifespan

Antimicrobial testing plays a crucial role in determining how long a coating will last. Microbially-induced corrosion (MIC) is a major concern, as sulfur-oxidizing bacteria can lower concrete’s pH from 12.5 to below 4 by producing corrosive sulfuric acid. Testing helps verify whether antimicrobial additives can halt this acidification process before it leads to irreversible damage.

Environmental stress tests, such as those under ASTM E2149-13, simulate real-world conditions like UV exposure and water immersion. These tests confirm whether antimicrobial agents remain active and chemically bonded over time. By doing so, they help prevent the bio-deterioration that causes cracks, staining, and premature coating failure.

sbb-itb-a0e5ae3

Testing Standards and Guidelines

Standardized protocols are essential for ensuring consistent antimicrobial testing results across different laboratories. Without these protocols, companies might either overestimate how effective their products are or fail to identify critical weaknesses. The EPA bases its evaluations of public health claims – especially those targeting human pathogenic bacteria – on strict adherence to these standards.

Below are examples of ASTM standards designed to address specific testing challenges.

ASTM Standards for Antimicrobial Testing

ASTM E2180-24 ($64.00) focuses on hydrophobic coatings that repel water-based solutions. To overcome the challenge of maintaining contact between bacteria and these surfaces, this standard employs an agar slurry to create a "pseudo-biofilm." This ensures uniform interaction with the treated surface. As the standard explains:

This method tests hydrophobic surfaces by using an agar slurry to ensure uniform contact.

For non-leaching antimicrobial agents, ASTM E2149-13 ($86.00) uses a dynamic shake flask test. The constant agitation in this method ensures microbes come into contact with the treated surface, addressing the limitations of static tests that could lead to false negatives.

ASTM C1904-20 ($80.00) is designed for concrete products, specifically targeting microbially induced corrosion (MIC). It evaluates how well antimicrobial additives prevent biogenic acidification, tracking the pH drop from an initial 12.5 to below 4. Another critical standard, ASTM E1054 ($86.00), focuses on neutralization procedures. It ensures that antimicrobial activity stops immediately after testing, avoiding overestimation of effectiveness. The standard emphasizes:

Inefficient or incomplete neutralization will permit killing or inactivation of microorganisms to continue beyond the experimental exposure time, resulting in an overestimation of antimicrobial activity.

ISO and EN Testing Protocols

In addition to ASTM standards, international ISO and EN protocols offer alternative testing methods tailored to different environments. For instance, ISO 22196:2011 tests under wet conditions, requiring over 90% relative humidity and a 24-hour incubation period at 95°F ± 1.8°F. On the other hand, ISO 7581:2023 (CHF 135, approximately $153.00) uses a dry testing approach, conducted at 30–65% humidity with a much shorter incubation time of just 1–2 hours.

The primary distinction lies in how the inoculum is applied. While ASTM E2180 uses an agar slurry, ISO 22196 employs a polyethylene cover film to spread the inoculum. ISO 7581, designed for dry environments, applies a 1 µL inoculum that is dried under a laminar flow hood before testing. This dry protocol specifically measures bactericidal action, making it ideal for surfaces that are typically dry.

| Standard | Environment | Incubation Time | Primary Application | Price |

|---|---|---|---|---|

| ASTM E2180 | Agar slurry (pseudo-biofilm) | 24 hours | Hydrophobic/polymeric surfaces | $64.00 |

| ASTM E2149 | Dynamic shake flask | Variable | Non-leaching agents | $86.00 |

| ISO 22196 | Wet (>90% humidity) | 24 hours | General antimicrobial activity | – |

| ISO 7581 | Dry (30–65% humidity) | 1–2 hours | Bactericidal activity | ~$153.00 |

| ASTM C1904 | Biogenic acidification | Variable | Concrete-specific MIC | $80.00 |

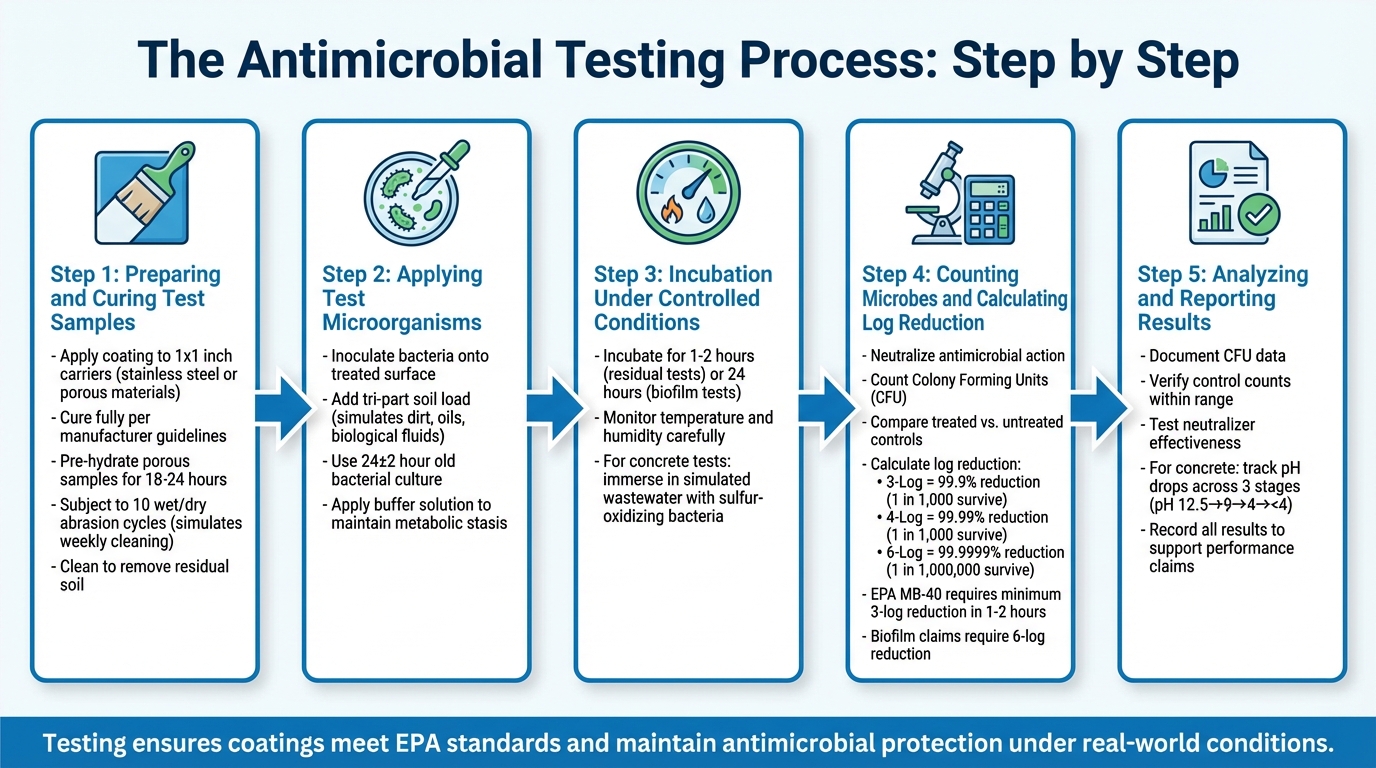

The Antimicrobial Testing Process: Step by Step

5-Step Antimicrobial Testing Process for Concrete Coatings

Laboratories follow a structured five-phase process to evaluate antimicrobial coatings under conditions that mimic actual use.

Step 1: Preparing and Curing Test Samples

The first step involves applying antimicrobial coatings for concrete floors to surfaces that resemble real-world installations. Commonly used carriers include 1 x 1 inch brushed stainless steel, although porous surfaces like concrete require cementitious or ceramic-like materials to reflect their natural porosity. Once applied, the coating must cure fully according to the manufacturer’s guidelines before testing begins.

For porous materials such as concrete, samples undergo pre-hydration by resting on a moistened wipe for 18 to 24 hours. This step prevents the substrate from pulling moisture from the microbial inoculum, which could otherwise lead to misleading results by dehydrating bacteria instead of relying on the coating’s antimicrobial properties.

To simulate real-life wear and tear, cured samples are subjected to 10 alternating wet/dry abrasion cycles, mimicking weekly cleaning routines. After this, surfaces are cleaned to remove any residual soil, leaving them ready for the application of microorganisms in the next step.

Step 2: Applying Test Microorganisms

Once the coating has cured, microorganisms are applied directly to the treated surface. For static surface testing, such as EPA SOP MB-40, bacteria are inoculated onto the 1 x 1 inch carriers. In dynamic tests like ASTM E2149, treated samples are immersed in a bacterial suspension and agitated in a shake flask to maximize contact between microbes and the antimicrobial surface.

To replicate real-world conditions, a tri-part soil load (organic matter) is added to the microorganism suspension. This simulates the presence of dirt, oils, or biological fluids that could interfere with the coating’s function. The bacterial culture is standardized at 24±2 hours old, and a buffer solution is used to maintain metabolic stasis, ensuring consistent conditions during testing. Once inoculated, the samples are moved to controlled incubation.

Step 3: Incubation Under Controlled Conditions

Samples are incubated under specific temperature and humidity levels as defined by the testing protocol. For residual antimicrobial tests, microorganisms are typically left on the surface for 1 to 2 hours. During this time, environmental conditions are carefully monitored to ensure accuracy.

In biofilm testing, samples are placed in a reactor where bacteria can adhere and develop into a mature biofilm matrix. For concrete-specific tests like ASTM C1904, samples are immersed in simulated wastewater containing sulfur-oxidizing bacteria to replicate microbially induced corrosion stages.

Step 4: Counting Microbes and Calculating Log Reduction

After incubation, the antimicrobial action is neutralized using a chemical neutralizer, ensuring that only surviving microbes are counted. Microbial populations are measured in Colony Forming Units (CFU) per test carrier or coupon.

The log reduction is calculated by comparing microbial counts from treated samples to untreated controls. Results are expressed as the mean log density of CFU counts across replicates.

| Log Reduction | Percent Reduction | Microbial Survival Rate |

|---|---|---|

| 3-Log | 99.9% | 1 in 1,000 survive |

| 4-Log | 99.99% | 1 in 10,000 survive |

| 6-Log | 99.9999% | 1 in 1,000,000 survive |

To meet the EPA MB-40 standard for residual antimicrobial coatings, a product must achieve at least a 3-log reduction (99.9%) within 1–2 hours. For biofilm claims, the EPA typically requires a minimum six-log reduction (99.9999%) across test coupons. As the EPA explains:

"Attain a minimum mean six log reduction (CFU/coupon) across five coupons in viable bacteria in biofilm."

- U.S. Environmental Protection Agency

These measurements confirm the coating’s effectiveness.

Step 5: Analyzing and Reporting Results

After counting CFUs, the data is analyzed and documented. For biofilm testing, control counts must fall within specific ranges: 8.0 to 9.5 CFU per coupon for Pseudomonas aeruginosa and 7.5 to 9.0 CFU per coupon for Staphylococcus aureus. Laboratories also test the neutralizer’s effectiveness for the specific antimicrobial batch to ensure accurate log reduction results.

For concrete-specific tests, as outlined in ASTM C1904, efficacy is determined by the coating’s ability to prevent pH drops across three stages: Stage I (pH 12.5 to 9), Stage II (pH 9 to 4), and Stage III (pH < 4). All results are meticulously recorded to support any claims about the product’s performance.

Common Microorganisms Used in Testing

In antimicrobial testing for concrete coatings, specific microorganisms are chosen based on their relevance to everyday and challenging environments. Two of the most commonly used are Staphylococcus aureus (a Gram-positive bacterium) and Escherichia coli (a Gram-negative bacterium). These two pathogens are frequently referenced in standard testing protocols like ISO 22196 and JIS Z 2801. Their widespread presence on surfaces makes them ideal baseline indicators for evaluating antimicrobial effectiveness. However, testing often expands to include organisms that thrive in harsher, moisture-heavy conditions.

For instance, high-moisture environments call for testing against Pseudomonas aeruginosa, a Gram-negative bacterium notorious for forming tough biofilms. These biofilms act as protective barriers, shielding bacteria from dehydration and disinfectants. According to the EPA, overcoming biofilm resistance requires a six-log reduction in bacterial count. This makes Pseudomonas aeruginosa a critical challenge organism in antimicrobial performance testing.

Fungal testing, on the other hand, focuses less on health risks and more on preventing visible damage caused by fungi. Organisms like Aspergillus niger, Chaetomium globosum, and Penicillium funiculosum are used to evaluate a coating’s ability to resist staining, odors, and material degradation. Chris Liu, Microbiology Lab Manager at Thomson Research Associates Inc., explains:

The antimicrobial is added at the point of manufacture to inhibit the growth of undesirable microorganisms, such as bacteria or fungi that cause staining, odors and/or material degradation.

These fungal tests, alongside bacterial assessments, provide a well-rounded analysis of a coating’s performance under various microbial threats.

For concrete-specific durability, sulfur-oxidizing bacteria (SOB) are used to replicate corrosive conditions found in environments like sewage systems. These bacteria convert sulfur compounds into sulfuric acid, which aggressively corrodes concrete through a process known as Microbially Induced Corrosion (MIC). Using ASTM C1904 standards, coatings are tested to see how effectively they can prevent pH drops during three stages of corrosion – from an initial pH of 12.5 down to levels below 4. The choice of test organisms is tailored to match the coating’s intended application, ensuring it performs effectively in its target environment.

Understanding Test Results and Performance Claims

Once antimicrobial testing is complete, interpreting the results becomes essential for evaluating how well a coating performs. One key metric is log reduction, which measures the percentage of live microbes eliminated. For example, a 3-log reduction means 99.9% of microbes are removed, while a 5-log reduction equates to 99.999%, and a 6-log reduction hits 99.9999% effectiveness.

The type of product being tested also plays a major role in how results are assessed. Residual disinfectants are required to achieve a 5-log reduction (99.999%) for bacteria within 10 minutes or less to meet EPA standards for stand-alone disinfection. On the other hand, supplemental residual coatings are designed to complement – not replace – routine cleaning. These coatings typically achieve a 3-log reduction (99.9%) within 1–2 hours and must meet EPA standards for this timeframe. For claims related to biofilms, the EPA sets an even higher bar, requiring a minimum 6-log reduction to deem a product effective against these tough microbial structures.

| Feature | Residual Disinfectants | Supplemental Residual Coatings |

|---|---|---|

| Performance Standard (Bacteria) | 5-log reduction (99.999%) | 3-log reduction (99.9%) |

| Contact Time | ≤ 10 minutes | 1–2 hours |

| EPA Standard Met | Meets disinfection standard | Does not meet disinfection standard |

| Usage | Stand-alone treatment | Supplement to standard disinfection |

These comparisons emphasize the need for clear and precise performance claims. Supplemental coatings, in particular, must include a label qualifier to avoid confusion, such as:

This product DOES NOT achieve the same level of efficacy as an EPA-registered disinfectant; it is only intended to provide supplemental protection.

It’s also critical to verify that the testing conditions and microbial challenges match the product’s intended application. For instance, just because a coating is proven effective against Staphylococcus aureus doesn’t mean it will work equally well against biofilms or viruses unless it has been specifically tested for those scenarios.

Durability testing is another essential step. Beyond initial efficacy, these tests confirm that antimicrobial performance holds up under real-world conditions. This involves subjecting the coating to 10–12 wet/dry abrasion tests cycles and exposing it to commonly used cleaning agents like bleach or hydrogen peroxide. Without such durability checks, even high initial log reduction values may fail to reflect long-term performance – especially on high-traffic surfaces like concrete floors that undergo daily cleaning.

Antimicrobial Testing and Croc Coatings‘ Penntek Evolution System

Croc Coatings’ Penntek Evolution system undergoes extensive testing to ensure dependable antimicrobial protection in high-traffic areas like garage floors, patios, pool decks, and commercial spaces. Its design allows it to work consistently between cleaning cycles – an essential feature for spaces where hygiene is a top priority.

The system’s antimicrobial properties are validated through ASTM E2180 testing, which confirms that antimicrobial agents are embedded within the polymer for long-term effectiveness. Additionally, EPA MB-40 testing simulates 1–4 weeks of cleaning using common disinfectants like bleach and hydrogen peroxide, ensuring the coating maintains its protective qualities under real-world conditions. To meet EPA standards for supplemental residual antimicrobial products, the coating must reduce microorganisms by at least 99.9% within 1–2 hours of contact.

Durability is another key strength of the Penntek Evolution system. Laboratory tests simulate weekly cleaning routines by applying 10 alternating wet/dry abrasion cycles, demonstrating that its antimicrobial agents remain active even after repeated wear. This ensures the coating continues to perform well beyond the initial weeks after installation.

The system has been tested against significant pathogens, including Staphylococcus aureus and Pseudomonas aeruginosa, offering broad-spectrum protection in environments prone to bacterial growth. For concrete surfaces, it also helps prevent microbial-induced corrosion (MIC) by delaying pH drops caused by biogenic acidification, effectively protecting the substrate beneath the coating.

Beyond its antimicrobial capabilities, the Penntek Evolution system boasts 4x the strength of epoxy, enhanced UV stability, and slip resistance, making it a reliable choice for long-term use. Whether it’s a residential garage, a pool deck, or a commercial kitchen floor, the coating provides an added layer of protection, particularly in areas where moisture fosters microbial growth.

These rigorous tests highlight Croc Coatings’ dedication to developing durable, high-performing antimicrobial solutions, reinforcing their commitment to quality in concrete coatings.

Conclusion: The Role of Antimicrobial Testing in Coating Quality

Antimicrobial testing plays a key role in ensuring that concrete coatings meet high standards for hygiene, durability, and long-term performance. Protocols like ASTM E2180 and EPA SOP MB-40 are designed to confirm that antimicrobial properties hold up against repeated cleaning and years of use. These tests not only assess immediate effectiveness but also validate how coatings perform over time.

This process tackles important quality concerns across both residential and commercial settings. For example, preventing microbially induced corrosion is crucial, as sulfur-oxidizing bacteria can significantly reduce pH levels – from 12.5 to below 4.0 – leading to potential substrate damage. Simulated wear tests ensure that antimicrobial agents remain effective even after repeated exposure to harsh disinfectants. To back hygiene claims, coatings must demonstrate at least a 99.9% reduction in pathogens like Staphylococcus aureus and Pseudomonas aeruginosa, ensuring they deliver residual antimicrobial protection.

Testing also verifies whether antimicrobial agents are securely bonded within the coating or risk being removed during regular maintenance. Standards like ASTM E2149 confirm that these agents are non-leaching, which is especially important in high-traffic areas where constant cleaning is unavoidable.

For property owners, verified testing ensures that coatings perform as promised. Whether it’s a garage floor, a pool deck, or a commercial kitchen, rigorously tested coatings provide reliable protection against bacteria, biofilms, and structural damage. At Croc Coatings, we rely on these thorough testing measures to uphold the reliability of our Penntek Evolution system, delivering dependable performance and durability for both residential and commercial applications. Antimicrobial testing is the foundation of quality and longevity for concrete coatings in any environment.

FAQs

What’s the difference between a residual disinfectant and a supplemental antimicrobial coating?

A residual disinfectant works by offering extended antimicrobial activity on a surface, steadily decreasing microbial presence over time. In contrast, a supplemental antimicrobial coating acts as an additional layer aimed at increasing resistance to microbial growth. These coatings are generally used in combination with routine disinfection methods to provide added protection.

Which test standards matter most for antimicrobial concrete coatings (EPA MB-40, ASTM, or ISO)?

The key test standard in the U.S. for antimicrobial concrete coatings is EPA MB-40-00. This standard focuses on assessing how effective antimicrobial surface coatings are against biofilm bacteria. While ASTM standards such as C1904-20 and E2180-24 offer testing methods for antimicrobial additives and incorporated agents, EPA MB-40-00 is the go-to standard for evaluating the performance of surface coatings.

How can I tell if antimicrobial protection will last after repeated cleaning and abrasion?

The strength of antimicrobial protection is often assessed using standardized tests developed by organizations like ASTM and EPA. These tests mimic real-world conditions, including repeated cleaning and abrasion, to determine how well a coating retains its antimicrobial properties over time.

Related Blog Posts

- ASTM D2794: Impact Resistance Test Explained

- UV Testing for Concrete Coatings Explained

- ASTM Standards for Chemical Resistance in Coatings

- How Antimicrobial Coatings Protect Concrete Floors