Adhesion Testing Methods for Concrete Coatings

February 15, 2026

When it comes to concrete coatings, adhesion strength is the foundation of durability. Without proper bonding, coatings can peel, blister, or delaminate, leading to costly repairs. Adhesion testing ensures that coatings perform as expected, especially in demanding areas like garages, pool decks, and industrial floors. Two main methods are commonly used:

- ASTM D7234 Pull-Off Test: Measures tensile force in psi or MPa, providing precise, quantitative results. Ideal for concrete and high-performance applications.

- ASTM D3359 Tape Test: A quick, qualitative method using a 0-5 scale to evaluate adhesion. Best for field inspections or thinner coatings.

For residential and industrial projects, testing confirms that coatings can handle traffic, chemical exposure, and environmental challenges. This is particularly important in regions like North Idaho and Eastern Washington, where conditions can be tough. Using systems like Penntek Evolution, which boasts adhesion four times stronger than epoxy, ensures long-lasting results.

Key Takeaways:

- Adhesion testing prevents coating failures by identifying weak bonds.

- The pull-off test offers precise measurements, while the tape test provides fast evaluations.

- Proper surface preparation and following ASTM standards are critical for accurate results.

Whether you’re coating a garage floor or an industrial workspace, adhesion testing is a critical step to ensure durability and performance.

8. How to Measure the Pull-Off Adhesion of Coatings on Concrete

This procedure is a critical part of how to assess concrete coating durability to ensure long-term performance.

sbb-itb-a0e5ae3

ASTM D7234 Pull-Off Test for Concrete Coatings

The ASTM D7234 pull-off test provides exact numerical results in pounds per square inch (psi) or megapascals (MPa). It’s the standard method for confirming that a coating meets the necessary performance criteria for demanding environments, such as high-traffic or industrial areas.

"The test determines the greatest perpendicular force (in tension) that a surface area can bear before a plug of material is detached." – ASTM International

Although this is a destructive test that requires repairing the removed coating section, it delivers highly dependable data.

How the Pull-Off Test Works

The test begins by attaching a cylindrical metal dolly to the coating surface using a high-strength adhesive. Before this step, the coating is scored down to the concrete substrate around the dolly’s exact diameter. This ensures the test measures adhesion only within the intended area.

Once the adhesive cures completely, a portable pull-off adhesion tester is connected to the dolly. The tester applies an increasing tensile force perpendicular to the surface until a plug of material detaches. The maximum force at failure is recorded. Afterward, the fracture surface is analyzed to determine if the failure was in the adhesive, within the coating layers, or in the concrete itself.

| Step | Procedure Description |

|---|---|

| 1. Preparation | Clean the surface and confirm the coating is fully cured. |

| 2. Scoring | Cut through the coating down to the substrate around the dolly area. |

| 3. Bonding | Attach the dolly to the coating using a high-strength adhesive. |

| 4. Testing | Use the tester to apply tensile force perpendicular to the surface. |

| 5. Detachment | Record the maximum force at the point of failure. |

| 6. Analysis | Examine the fracture surface to identify the failure mode (adhesive, cohesive, or substrate). |

Precision is key. Misalignment during the test can produce uneven stress, leading to inaccurate results. Additionally, the adhesive must be fully cured and free from air bubbles to ensure the glue bond doesn’t fail prematurely.

Advantages of the Pull-Off Test

One of the primary benefits of this test is its accuracy. Instead of relying on subjective assessments, it provides a precise measurement of the force a coating can endure. This makes it particularly effective for confirming that coatings meet stringent industrial specifications.

Another plus is its adaptability. The test can be performed on a variety of coatings, including epoxies, polyurethanes, acrylics, and sealers. It’s suitable for both laboratory and field testing. By identifying weak adhesion points early, the test helps avoid costly coating failures in the future.

"This test is essential in assessing the coating performance, specifically its ability to adhere to a concrete surface." – Infinita Lab

The test also offers failure mode analysis, allowing you to determine the weakest point in the system. Whether the issue lies in surface preparation, a specific coating layer, or the concrete substrate itself, this analysis provides valuable insights.

Applications of the Pull-Off Test

The ASTM D7234 test is indispensable in high-performance settings where coating durability is non-negotiable. It’s commonly used for industrial floors in warehouses, manufacturing plants, bridges, chemical containment structures, and facilities in the automotive or aerospace industries.

For residential projects, such as garage floors or pool decks, the test ensures coatings can handle heavy traffic, chemical exposure, and environmental challenges. Products like Croc Coatings‘ Penntek Evolution system, which is four times stronger than epoxy, are specifically designed for these rigorous demands. The pull-off test confirms the system’s superior adhesion strength, making it ideal for applications across North Idaho and Eastern Washington, including Spokane and the Tri-Cities.

Professional ASTM D7234 testing services typically start at around $100, depending on sample quantity and site conditions. For those seeking detailed technical guidance, the ASTM D7234-22 standard document is available for $72.00. Up next is the ASTM D3359 tape test, a faster method for qualitative adhesion evaluation that complements the pull-off test’s detailed results.

ASTM D3359 Tape Test Method

The ASTM D3359 tape test offers a quick and affordable way to assess adhesion. Unlike the pull-off test, which provides exact numerical data, this method uses pressure-sensitive tape to evaluate how well a coating sticks to concrete. Results are rated visually on a scale from 0 to 5, where 5 means no peeling and 0 indicates severe removal.

This test applies shear forces – forces parallel to the surface – rather than perpendicular ones. This approach mimics real-world peeling or undercutting scenarios, making it helpful for identifying adhesion issues that tensile tests might miss.

"The shear tests are oftentimes more definitive because they better replicate the way in which coatings fail. That is, coatings generally do not disbond from a substrate or other coating as a result of forces that are exerted perpendicular to the surface." – KTA University

Although originally designed for metal, the ASTM D3359 method works well on concrete. The official standard spans eight pages and costs $86.00.

How the Tape Test Works

The tape test can be performed using two standard methods:

- Test Method A (X-Cut): Best for field inspections and coatings over 5 mils (125 µm) thick. An "X" is cut into the coating at a 30°–45° angle, ensuring the cut reaches the substrate.

- Test Method B (Cross-Cut): Used in labs for coatings thinner than 5 mils. A lattice pattern is cut into the coating: 11 cuts spaced 1 mm apart for coatings up to 2.0 mils thick, or 6 cuts spaced 2 mm apart for coatings between 2.0 and 5.0 mils.

After making the cuts, pressure-sensitive tape is applied using a pencil eraser to ensure even contact. The tape stays in place for about 60 seconds before being removed quickly at an angle close to 180°. The resulting damage is visually rated, with scores of 4 or 5 indicating good adhesion.

For consistent results, operators must maintain uniform cut depth, tape pressure, and removal angle. Using a metal straightedge helps keep cuts straight, and blades should be replaced often since concrete dulls them quickly. If the surface is heavily chalked, the chalk layer should be removed before testing to assess the coating itself.

Strengths and Weaknesses of the Tape Test

The tape test stands out for its simplicity and speed. With just a knife, tape, and straightedge, it’s perfect for quick quality checks and field inspections. Plus, it’s non-destructive, leaving only minor cuts that are easy to repair.

That said, it’s not without its limitations. The test is qualitative, offering visual ratings rather than precise bond strength measurements in psi or MPa. It’s also less effective for detecting small adhesion differences and isn’t suitable for materials like acrylic elastomeric coatings on cement or stucco, which may peel too easily after cutting – even if their bond strength is acceptable.

| Feature | ASTM D3359 (Tape Test) | ASTM D7234 (Pull-Off Test) |

|---|---|---|

| Measurement Type | Qualitative (0–5 scale) | Quantitative (psi or MPa) |

| Force Applied | Shear (parallel to surface) | Tensile (perpendicular to surface) |

| Best Use Case | Quick field screening/quality control | Engineering evaluations |

| Equipment Cost | Low (knife, tape, straightedge) | Higher (portable tester) |

| Sensitivity | Low; detects only large differences | High; distinguishes fine variations |

The tape test complements the pull-off test by offering a fast, qualitative way to spot adhesion issues. For routine inspections or preliminary checks, it’s a practical tool. However, for critical applications like industrial floor coatings or high-traffic areas, where precise adhesion data matters, the ASTM D7234 pull-off test is the better choice. At Croc Coatings, we use both methods to ensure our concrete coatings meet the highest adhesion standards for long-lasting performance.

Factors Affecting Adhesion Test Results and Best Practices

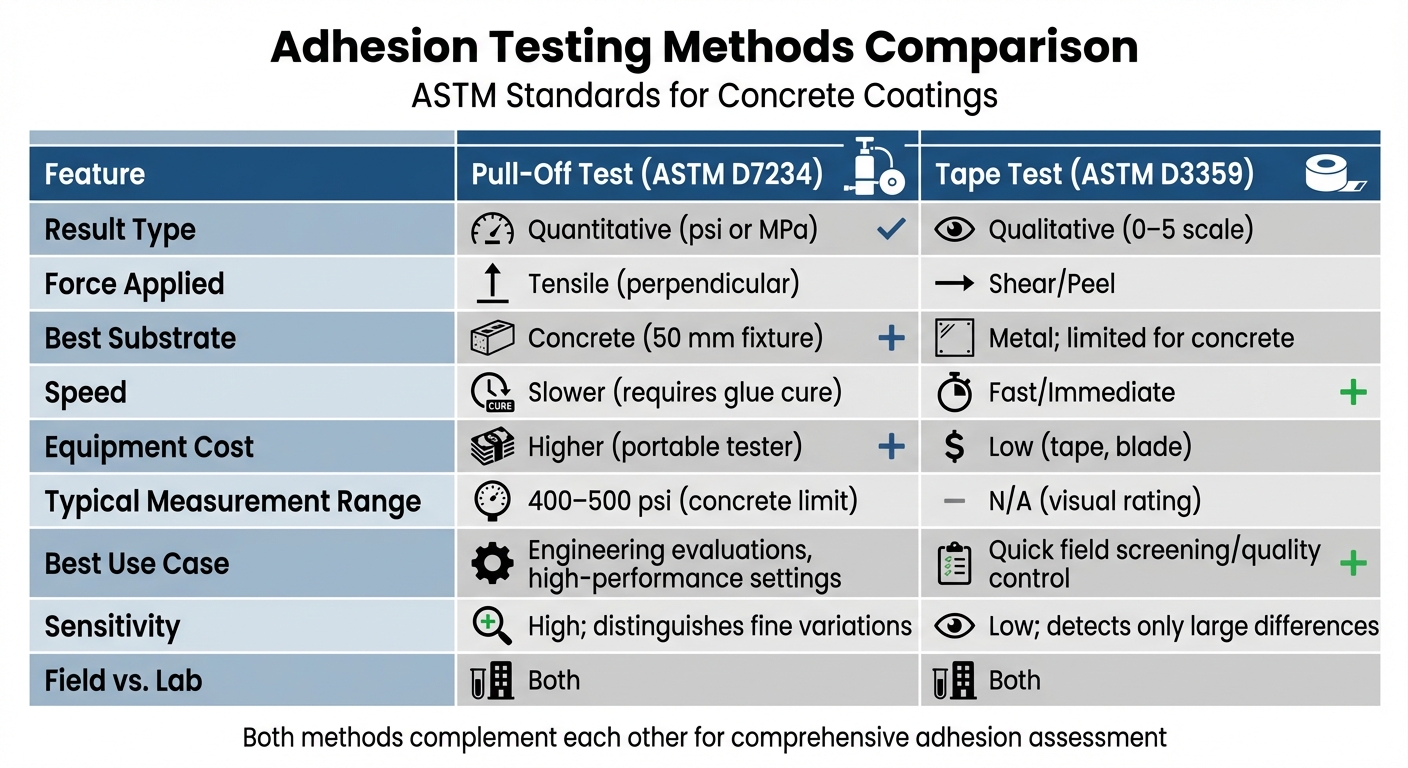

ASTM D7234 Pull-Off Test vs ASTM D3359 Tape Test Comparison Chart

Key Variables Impacting Test Results

Accurate adhesion test results hinge on managing several critical factors. Surface contaminants like grease, oil, dirt, chalking paint, or even moisture in concrete can throw off readings, making it essential to start with a properly prepared surface.

Cure time and coating type are other major players. Testing before a coating has fully cured leads to unreliable results. Factors like low temperatures or high humidity can extend cure times, so always check the manufacturer’s guidelines for the specific site conditions. Concrete, as a substrate, adds its own challenges. With a typical tensile strength of 400–500 psi, concrete often fractures before the coating bond fails, making it hard to assess the coating’s true adhesion strength.

Environmental factors, such as temperature and humidity, also influence test outcomes. These conditions impact not only the performance of the coating but also the adhesives and tapes used in testing. For pull-off tests, the glue type and its curing behavior are crucial. If the glue fails instead of the coating – a result known as a "glue break" – and this occurs over more than 25% of the loading area, the test is deemed invalid.

Understanding these variables is key to comparing the effectiveness of different adhesion tests, as summarized below.

Comparison of Test Methods

| Feature | Pull-Off Test (ASTM D7234) | Tape Test (ASTM D3359) | Knife Test (ASTM D6677) |

|---|---|---|---|

| Result Type | Quantitative (psi or MPa) | Qualitative (0–5 scale) | Subjective/Qualitative |

| Force Applied | Tensile (perpendicular) | Shear/Peel | Shear/Peel |

| Best Substrate | Concrete (50 mm fixture) | Metal; limited for concrete | Rigid surfaces |

| Speed | Slower (requires glue cure) | Fast/Immediate | Fast/Immediate |

| Equipment Cost | Higher (portable tester) | Low (tape, blade) | Low (utility knife) |

| Typical psi Range | 400–500 psi (concrete limit) | N/A (visual rating) | N/A (subjective) |

| Field vs. Lab | Both | Both | Field (quick checks) |

These factors highlight the strengths and limitations of each method, which is why following best practices is so important for reliable results.

Best Practices for Adhesion Testing

Start with proper surface preparation. Clean the test area thoroughly and ensure it’s completely dry before applying adhesives or tape. For pull-off tests, use 50 mm (2-inch) fixtures and, for coatings thicker than 20 mils, score down to the substrate to avoid interference from lateral bonds.

Conduct at least three replicate tests in each area. A single low reading might indicate a localized issue or testing error. Also, calibrate your equipment regularly – ideally on the manufacturer’s schedule or at least every three years. When testing concrete coatings, keep the loading rate under 30 psi per second, completing the test within 5 to 30 seconds.

"The accuracy and precision of the test result obtained by using [tape] methods depends largely upon the skill of the operator and the operator’s ability to perform the test in a consistent manner." – ASTM D3359-23

Document everything – temperature, humidity, cure times, and observed failure modes. Self-aligning testers, such as PATTI or PosiTest AT, help achieve more consistent pull-off values by compensating for uneven concrete surfaces. At Croc Coatings, we adhere to these protocols rigorously, ensuring our Penntek Evolution industrial coating system meets the highest standards. This meticulous approach supports our claim of delivering a coating system that’s four times stronger than epoxy, backed by adhesion testing that surpasses industry benchmarks.

Conclusion

Key Takeaways

Adhesion testing plays a crucial role in verifying the durability of coatings. Whether you’re using the pull-off test (ASTM D7234) to measure tensile strength or the tape test (ASTM D3359) for quick evaluations, both methods provide essential insights into the bond between a coating and its substrate. These tests not only identify the weakest bond plane but also confirm whether surface preparation was done correctly.

For context, concrete typically has tensile strengths ranging from 400 to 500 psi. However, high-performance polyaspartic systems like Penntek Evolution deliver average adhesion pull-off strengths of 891 psi – making them 178%–222% stronger than the concrete itself. In practice, this means the bond strength surpasses the concrete’s strength, leading to substrate failure rather than adhesive failure during testing. These results highlight the importance of rigorous testing for demanding applications.

Croc Coatings ensures quality by following ASTM-compliant protocols for every installation in North Idaho and Eastern Washington. Using the Penntek Evolution industrial coating system, which boasts adhesion performance four times stronger than epoxy, they back their work with a lifetime warranty for residential installations. This level of performance is achieved through thorough surface preparation, proper curing, and strict adherence to ASTM standards.

FAQs

What pull-off psi value is considered “good” for a garage or industrial floor coating?

A pull-off psi value exceeding 900 psi is regarded as "good" for garage or industrial floor coatings. Coatings with this level of adhesion strength are built to last, typically enduring 15–20 years while standing up well to wear and tear.

When should I use the tape test instead of the pull-off test on concrete?

The tape test is a handy tool for quick and portable adhesion checks, particularly for coatings thinner than 125 µm (5 mils). It’s a non-destructive method, making it a go-to option when you need to evaluate surface adhesion without causing damage. This is especially useful for coatings that don’t demand the more invasive pull-off test.

What causes an adhesion test to fail even if the coating looks fine?

When an adhesion test fails, it might seem puzzling, especially if the coating looks perfectly fine. However, appearances can be deceiving. Factors like poor surface preparation, lack of adequate surface roughness, moisture presence, or incorrect application techniques can all undermine the bond strength. Even though the coating might look intact, these underlying issues can significantly weaken its adhesion.

Related Blog Posts

- Why Adhesion Strength Matters for Concrete Coatings

- Top Abrasion Tests for Concrete Coatings

- How To Assess Concrete Coating Durability

- How to Check Concrete Coating Adhesion